24

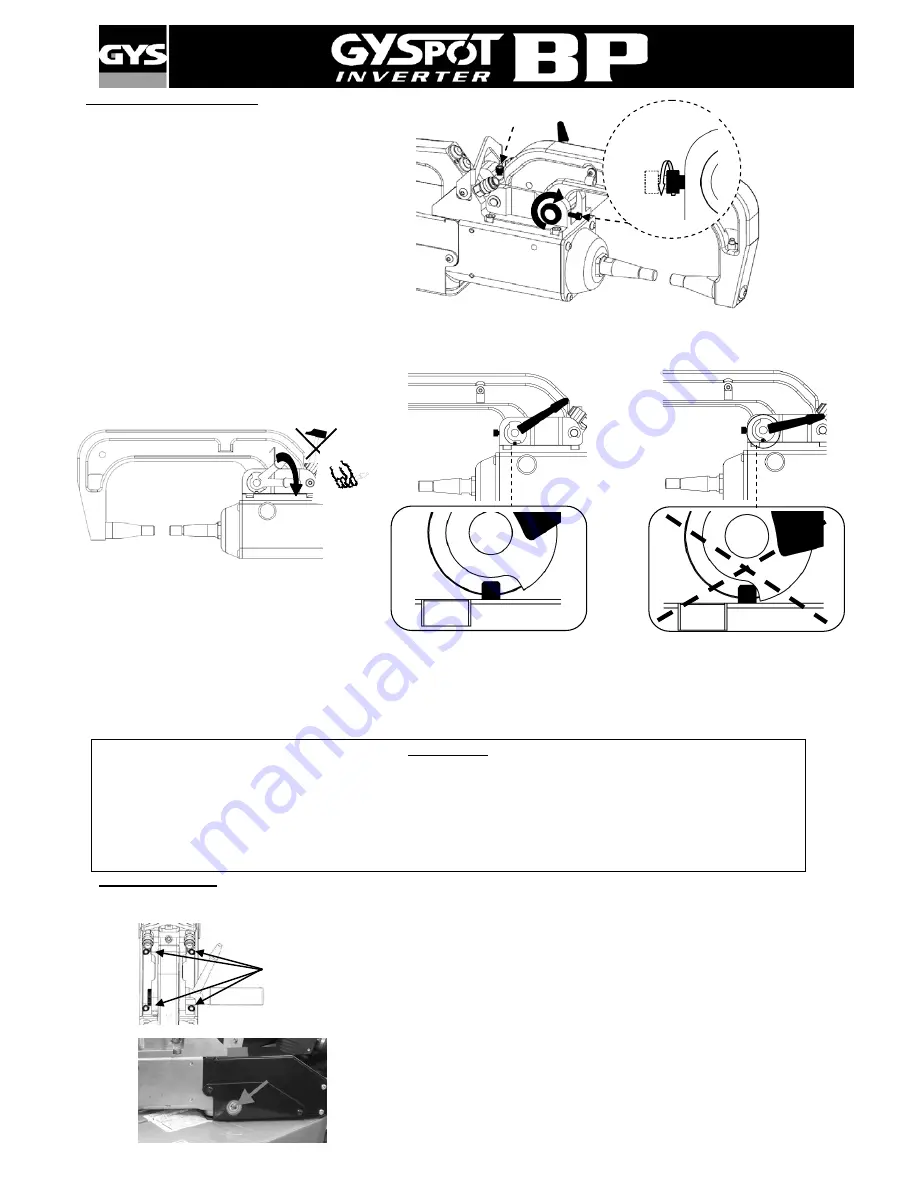

Adjustment of the C arms :

Ⓓ

♦

Position screw

to fix the arm on the

clamp. Tighten it in manually - do not over-

tighten.

♦

Tighten ring

manually, then the tighten

using the Allen key.

Ⓔ

♦

Tighten the lever manually and check it is not end up against the joint stop (see diagram below).

If it is the case go back to step

Ⓓ

.

Warning: Clamp and arm may be damaged if the lever is not tightened properly.

Ⓕ

♦

Check the cooling liquid level.

♦

Check screws and lever, incorrectly tightening can damage the material.

♦

Switch on the machine.

ATTENTION:

The clamps and gun are connected to the same power supply, therefore when one is in use, current will be

delivered to all tools. For safety, ensure sure that the clamps and gun are always placed on the trolley when

not in use (clamp stand on either side of the trolley, and the gun stand on the arm). Failure to follow this

precaution may result in serious damage to the user, the generator and its tools, and there is a high risk of

sparks and metal spatter. The warranty does not cover damages and defects due to a bad tightening or

assembly of the C arms.

C clamp overhaul :

The tightening of the following screws need to be inspected every month:

Screw between the arm and the clamp:

Serrer

These 4 screws fix the arm to the clamp. They need to be tightened to

ensure good transmission of the current. A loose/bad connection leads to

loss of current and even worse can cause irreversible damage to the arm

or clamp.

max

OK

NO

The screw shown opposite ensures secure attachment of the copper cable

which carries current to the clamp. It is recommended that screw tightness is

checked every month to prevent irreversible damage inside the clamp.