27

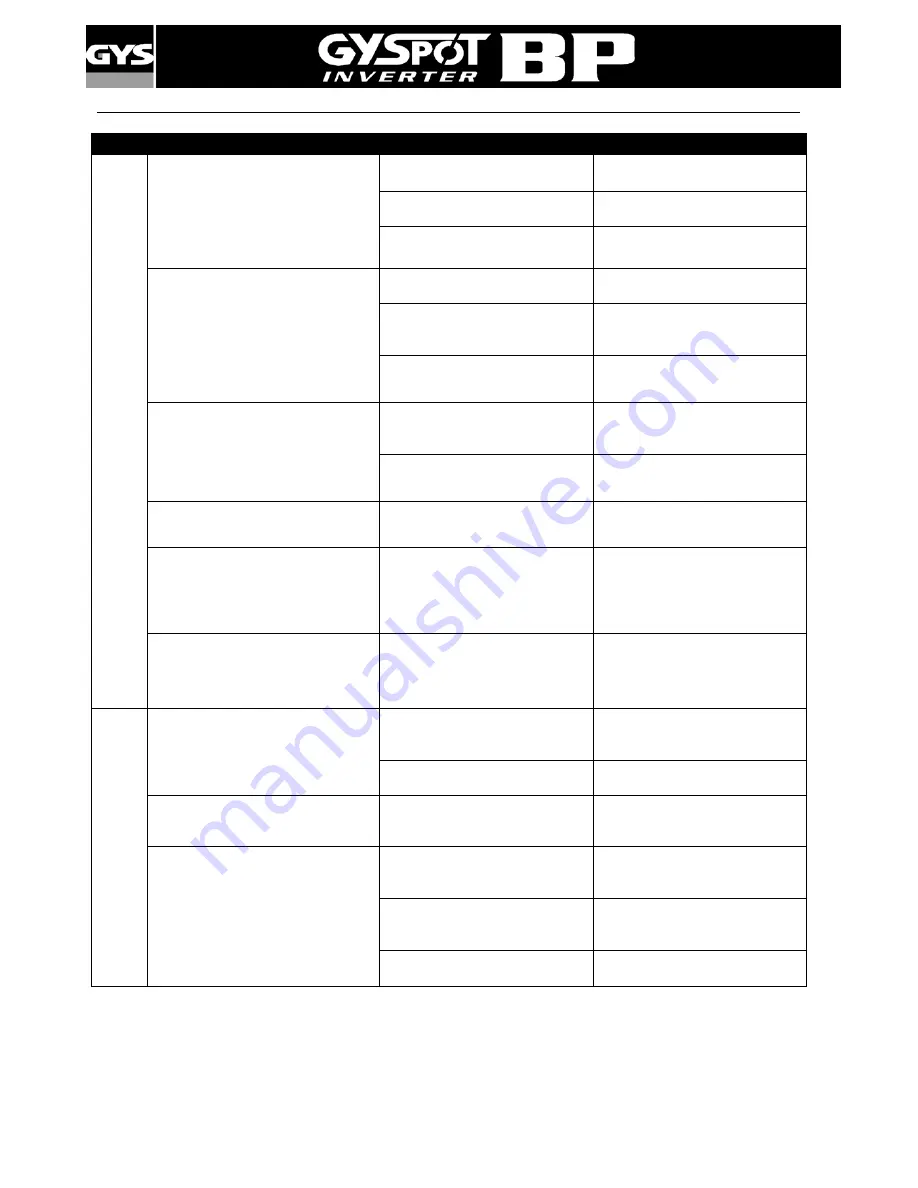

6-SYMPTOMS / REASONS / SOLUTIONS

SYMPTOMS

REASONS

SOLUTIONS

C

la

mp

The Spot weld doesn’t hold / is

not good

The caps used are worn

out/faulty

Replace the caps

Insufficient preparation of the

work-piece

Sand and clean the metal

sheet again

The arm selected doesn’t

match the one installed

Check the arm with the

software

The spotter cuts the metal

The caps used are worn

out/faulty

Replace the caps

Not enough pressure

Check the compressed air

network

(min. 7 bar)

Insufficient preparation of the

work-piece

Sand and clean the metal

sheet again

Lack of power at the clamps (C

and X)

Power supply issue

Check the stability of voltage

delivered

Caps worn out or damaged

Change the caps

Lack of power only at the C clamp

Bad tightening of the arm

Please follow the instruction in

the C arm adjustment chapter

GYSPOT BP.LCX

Machine overheats quickly.

Power cable expands.

Excessive pressure when

changing the X arm.

C arm missing on the the C

clamp.

C arm cooling pipes are

disconnected

Assemble the C arm on the C

clamp.

Connect the C arm cooling

pipes

GYSPOT BP.LC

Machine overheats quickly.

Power cable expands.

C arm cooling pipes are

disconnected

Connect the C arm cooling

pipes

W

el

di

ng

G

un

Abnormal overheating of the gun

Bad tightening of the chuck

Check the tightening of the

chuck, the star support chuck,

and the liner condition.

Gun liner out

Put back the liner to have the

air cool going to the gun

The spot weld made doesn’t hold

Bad positioning of the earth

clamp

Check the earth clamp is

securely connected to the

metal sheet

Lack of power in the gun

Bad contact of the earth clamp

Check the earth clamp is

securely connected to the

metal sheet

Loose chuck or accessories

Check the tightening of the

chuck and accessories, and the

condition of the liner

Worn out / Damaged

consumables

Replace the consumables