8

Using pneumatic clamps

When using the pneumatic clamp, always disconnect the copper plate used in single sided gun welding.

For the GYSPOT BP.LCX, select the type of clamp to be used with the

key on the front panel.

BP-LCX : to ensure the efficiency of the cooling system, it is essential that both clamps (C and X)

are equipped with their respective arms, and that the pipes are properly attached to their

respective connectors

ATTENTION :

The clamps and gun are connected to the same power supply, therefore when one is in use, current will be

delivered to all tools. For safety, ensure sure that the clamps and gun are always placed on the trolley when

not in use (clamp stand on either side of the trolley, and the gun stand on the arm). Failure to follow this

precaution may result in serious damage to the user, the generator and its tools, and there is a high risk of

sparks and metal spatter.

C clamp

♦

Tighten the C-clamp using the locking lever and check that the screw between the arm and the clamp is correctly

tightened.

♦

The clamping force is calculated by the machine, considering the force setting or the thickness of the sheets selected.

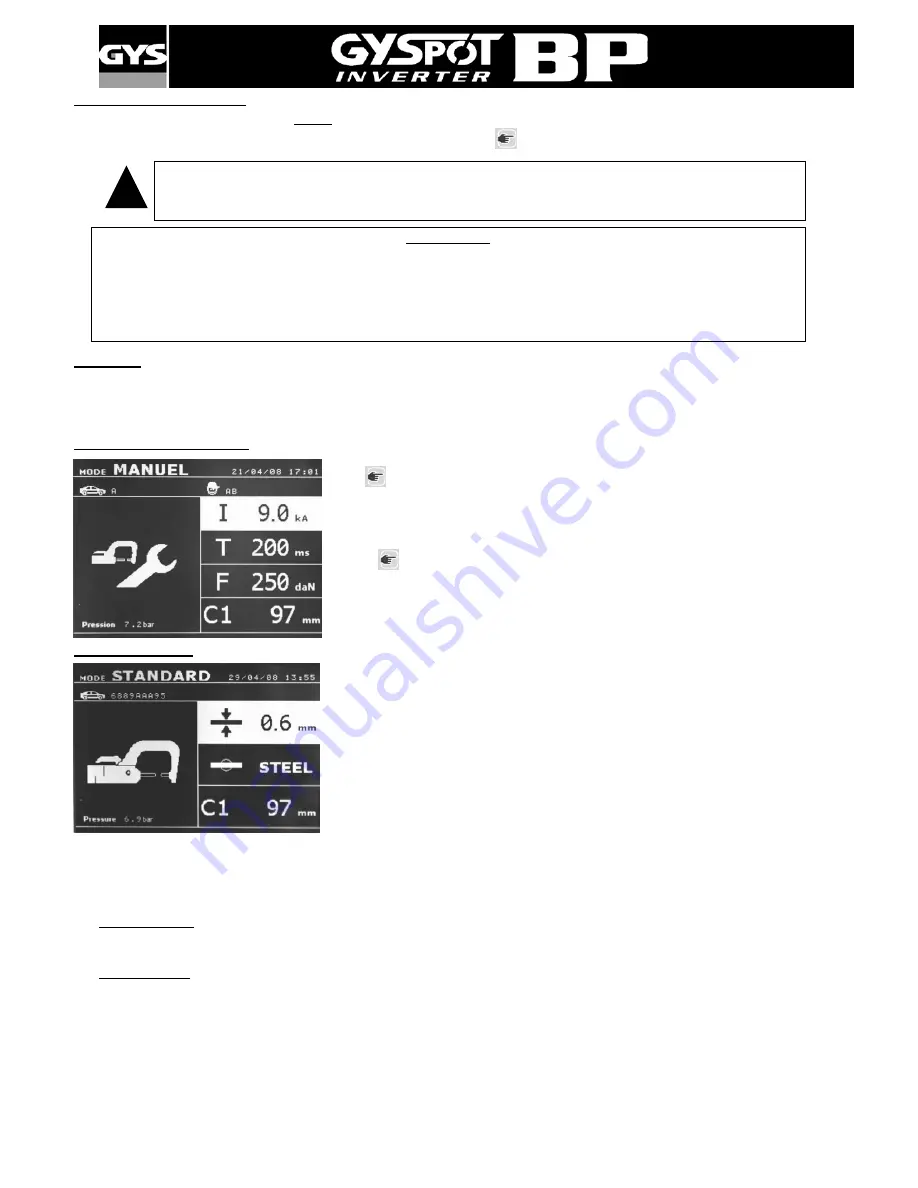

C clamp adjustment mode :

The

key is used to enter the clamp adjustment mode. The clamp adjustment

mode allows the user to close the clamp and apply the programmed force on the

electrodes without any current flowing. This mode is used to adjust the arms.

The clamp will remain closed as long as the button remains pressed; this allows

the user to check the alignment of the electrodes and positioning of the caps.

Press

for 2 seconds to revert back to standard mode.

STANDARD mode :

This is the default mode when the machine starts. Quick and easy spot welding

by selection of:

♦

the type of the tool used,

♦

the metal sheet thickness to select between :

0.6, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.5, 3.0.

When welding 2 metal sheets together, enter the thickness of the thinner one.

When welding 3 metal sheets together, enter the total thickness divided by 2.

♦

the type of metal sheet (coated steel, HTS steel, UHTS steel, BORON steel)

and the arm used.

For the type of metal, select the harder one.

♦

The up and down button (key definition diagram, (3) ) scrolls through the

parameters to modify (sheet thickness, type of steel, arm used). The + and –

keys allow modification of each parameter

Button A on the clamp allows the user change the thickness of the sheets to be welded remotely.

Button B on the clamp allows the user to spot weld with the selected parameters.

Before the weld: If the input air pressure is too low to reach the required electrode force, a warning will sound, and the

machine will display the error message “Pressure too low”. Pressing the button for a second time will force the execution of

the welding spot with the available air pressure.

After the weld: If the welding current measured during the spot is 6% less than the setting, the machine will display the

error message “Current too low” - the welding spot should be checked.

A message will be displayed at the end of every welding spot, showing the measured welding current and electrode force.

This message is displayed on the screen until a key on the control panel is pressed, or until a new welding spot is

performed, by pressing the B button on the clamp.

!