9

b.

Visually check all hydraulic connections (cylinders, hoses, couplings, power pack) for hydraulic leakage. If you notice a slight

leak, tighten the connection until there is no more leakage. If you see a large leak, immediately press "DN" (down) until the

QUICK LIFT is lowered to the ground. Tighten the connection firmly and repeat the test until there is no more leakage.

It is advisable to place a cardboard box between the floor and the QUICK LIFT

and even at the level of the quick connections in order to identify possible leaks

more easily during the first start-up.

Be meticulous when applying a sealing tab or Teflon to hydraulic connections. Do

not pollute or clog the hydraulic system. There are filters that could become

clogged and prevent the QUICK LIFT from working properly.

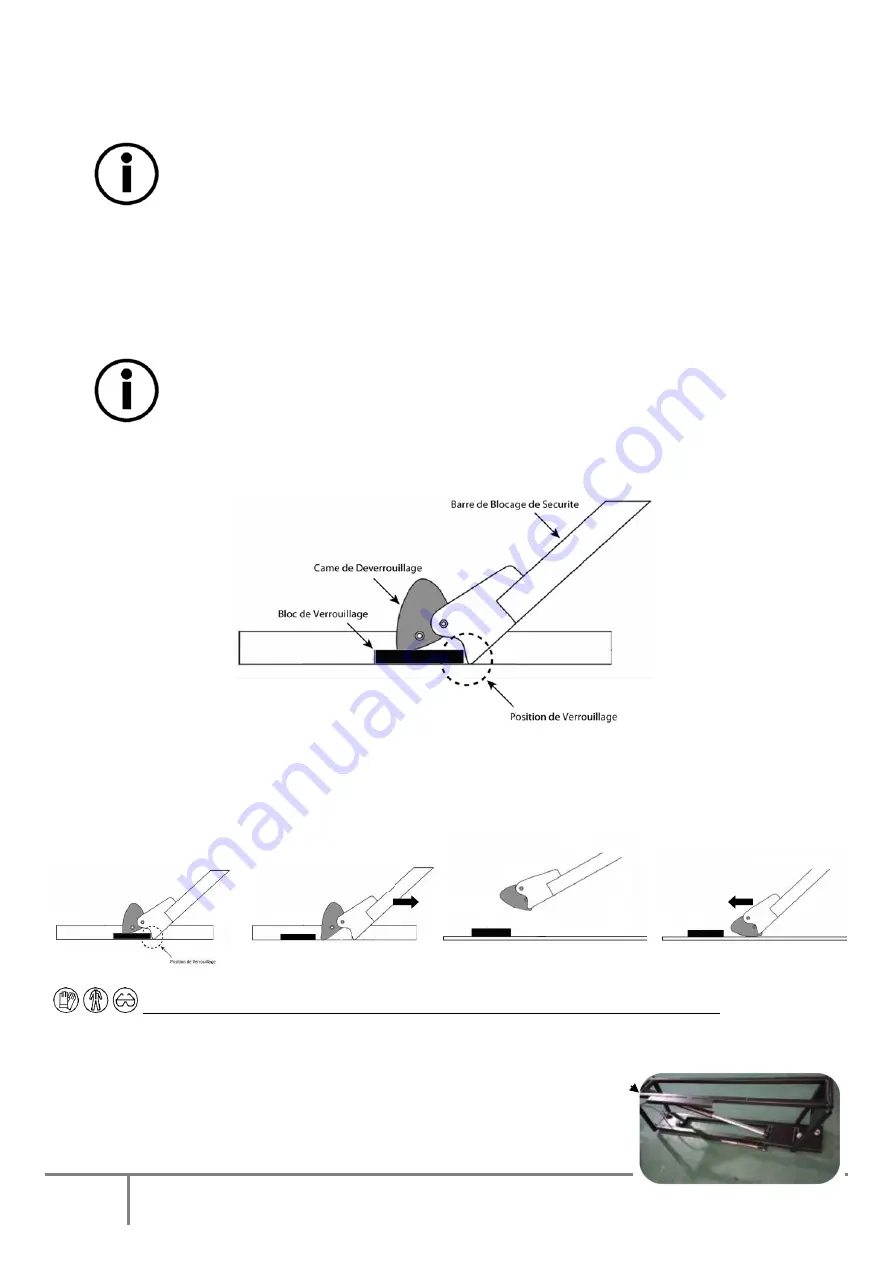

3/ CHECKING THE SAFETY SYSTEM AT HEIGHT 1:

Press "UP" again and move a few centimetres higher than height 1 so that the safety devices of both ramps protrude

a few centimetres above the locking block at height 1.

When empty, there may be a greater offset in the height of the ramps in relation

to each other and therefore in the passage of the locking bars on the blocks. This

is normal. On load, the ramps will be synchronized and the offset will be

corrected.

Pressing "DN" (down) will lower the ramps until both locking levers are in the locked position as shown in the diagram

below.

4/ DOWN THE RAMPS TO THE GROUND:

a.

Press "UP" to raise the QUICK LIFT by 2-3cm and then raise the safety locking bars with your hand or foot so that the

unlocking cam can come into contact with the ground when it is in its resting position.

b.

Make sure both release cams are resting on the ground before pressing "DN" (down).

c.

Press "DN" (down) until QUICK LIFT has returned to the initial position.

5/ PURGE THE WORMS:

Make sure you have the necessary protection: pair of glasses, safety shoes and gloves.

There may be air in the hoses or cylinders before first use. Unlike hydraulic oil, air is compressible. You might get the

impression that the ramps work like a shock absorber. To expel the air, it is necessary to bleed the circuit through the

cylinders.

Turn over the 2 ramps of your QUICK LIFT as shown in the photo opposite, taking

care not to injure yourself or get your fingers caught in the mechanical structure

(carry out this operation with 2 people if necessary) and follow the procedure for

Height 1

« UP »

« DW»

Summary of Contents for LUXMAIN QUICK LIFT L520E

Page 17: ...17...