20

MAGYS 400-4 / 400 GR / 500 GR / 500 WS

EN

RISK OF INJURY DUE TO MOVING PARTS

The wire feeders contain moving parts that may catch hands, hair, clothes or tools and lead to injuries!

• Do not touch rotating / moving / feeding parts of the machine!

• Make sure that all panels remain closed when in use!

• Do not wear gloves when setting up the wire and changing the wire reel.

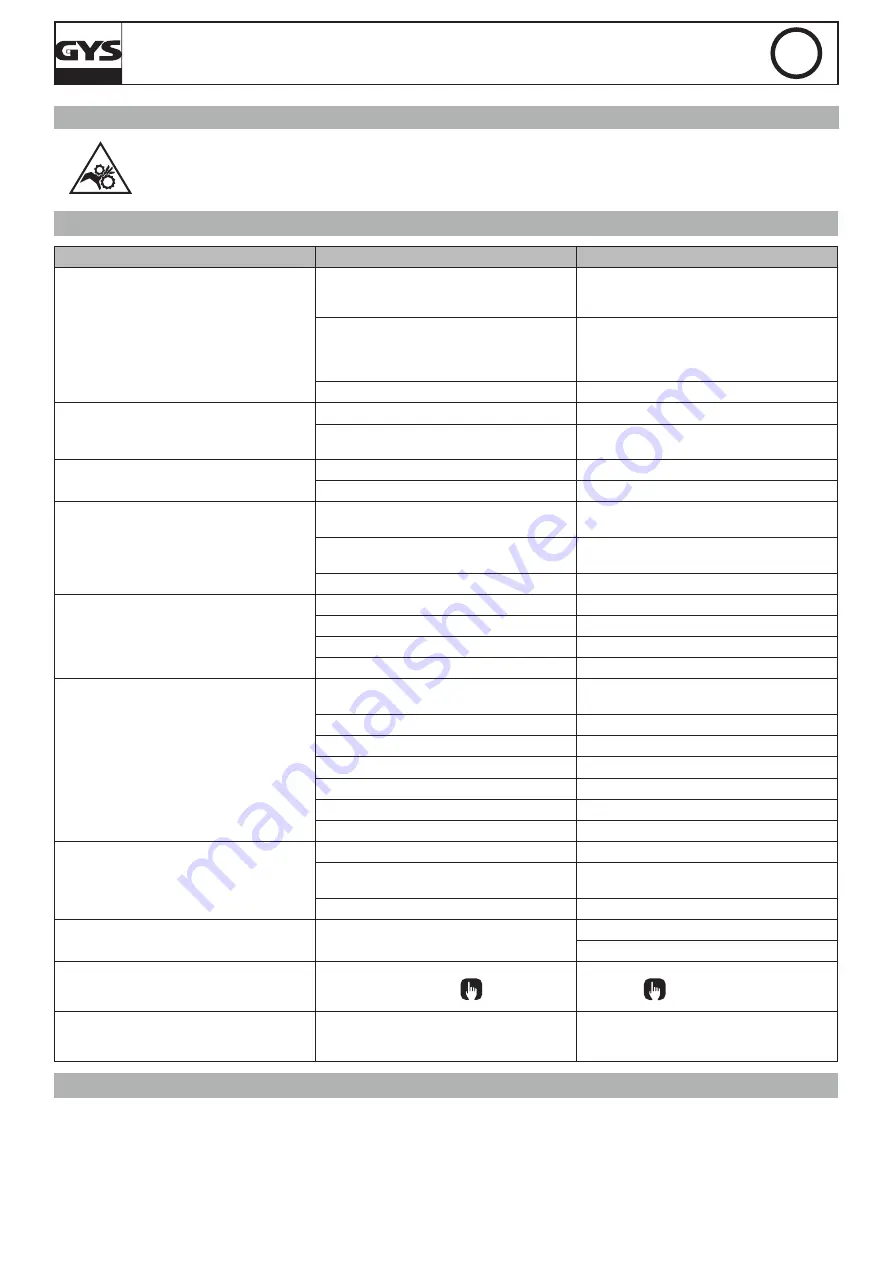

TROUBLESHOOTING

SYMPTOMS

POSSIBLE CAUSES

REMEDIES

The welding wire speed is not constant.

Debris is blocking up the opening.

Clean out the contact tip or change it and

replace the anti-adherence product.

Ref. 041806

The wire skids in the rollers.

• Check the roller pressure or replace it.

• Wire diameter incompatible with roller

• Covering wire guide in the torch incompa-

tible.

The rollers slide over the wire

Check and tighten the roller’s screws.

The wire-feeder motor doesn’t operate.

Reel or roller brake too tight.

Adjust the brake and rollers.

Electrical supply problem.

Check that the power switch is in the "On"

position.

Bad wire feed.

Covering wire guide dirty or damaged.

Clean or replace

Reel brake too tight

Adjust the brake

No welding current

Bad connection to the main supply.

Check the mains connection and ensure the

supply is 400 V (3PH).

Bad earth connection.

Check the earth cable (connection and clamp

condition).

Torch trigger inoperative.

Check the torch trigger / replace torch

The wire jams (after the rollers)

Guide wire sheath crushed.

Check the sheath and torch body.

Wire jammed in the torch

Clean or replace.

No capillary tube.

Check the presence of capillary tube.

Wire speed too fast

Reduce the wire speed

The welding bead is porous

The gas flow rate is not sufficient.

Adjust flow range 15 to 25 L / min.

Clean the work-piece.

Gas bottle empty.

Replace

Gas quality unsatisfactory.

Replace

Air flow or wind influence.

Prevent drafts, protect welding area.

Gas nozzle dirty.

Clean or replace the gas nozzle.

Poor quality wire.

Use suitable WIRE for MIG-MAG welding.

Work-piece in bad condition. (rust, etc…)

Clean the metal before welding.

The arc produces a lot of sparks

Arc voltage too low or too high.

See welding settings.

Bad earth connection.

Check the earth cable (connection and clamp

condition)

Insufficient gas flow.

Adjus the gas flow.

No gas flow at the end of the torch.

Bad gas connection.

Check that the gas pipe is plugged properly.

Check the solenoid valve.

When powering on:

The display (9) shows « Err » and the display

(10) shows « 002 ».

At least one of the 3 keys

is pressed.

The 3 keys

must be released.

When powering on:

The display (9) shows « Err » and the display

(10) shows « 001 ».

The Torch’s trigger is pressed.

The trigger must be released.

WARRANTY

The warranty covers faulty workmanship for 2 years from the date of purchase (parts and labour).

The warranty does not cover:

• Transit damage.

• Normal wear of parts (eg. : cables, clamps, etc..).

• Damages due to misuse (power supply error, dropping of equipment, disassembling).

• Environment related failures (pollution, rust, dust).

In case of failure, return the unit to your distributor together with:

- The proof of purchase (receipt etc ...)

- A description of the fault reported