43

GYSPOT INVERTER PTI.G

EN

The manufacturer does not accept any liability in relation to damages caused to objects or harm caused to persons as the result

of incorrect and/or dangerous use of the machine.

MAINTENANCE / RECOMMENDATIONS

• The operators must have received suitable training in order to use the machine at its maximum potential and weld correctly.

• Check which welding process is authorised by the manufacturer before attempting any vehicle repair.

The maintenance and repair of the machine can only be undertaken by the manufacturer. Any work undertaken by a third party on

the machine will invalidate the warranty. The manufacturer will not accept liability in the event of an incident that would occur after

this work was undertaken.

Ensure the machine is unplugged from the mains, and then wait 2 minutes before carrying out maintenance work. Inside the

machine, voltage and current levels are high and dangerous.

• Prior to any work on the machine, turn the air supply off and depressurise the circuit of the machine.

• Make sure to purge the filter of the dehumidifier located at the back of the machine regularly.

• The device is fitted with a balance system designed for easier handling. However, it is not recommended to leave the clamp hanging at the end of

the cable of the balancing system for prolonged periods of time as it might increase wear. Do not drop the clamp repetitively or it might damage the

balancing system.

• It is possible to adjust the tension of the balancing system spring using the spanner provided.

•The level of the cooling liquid is important for the machine to work correctly. It must always be between the «minimum» and «maximum» marks on

the machine. Regularly check the level and top-up when needed.

• It is recommended to renew the cooling liquid every 2 years.

• All the welding tools will wear off with use. Ensure that these tools are clean to get the best results.

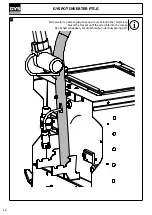

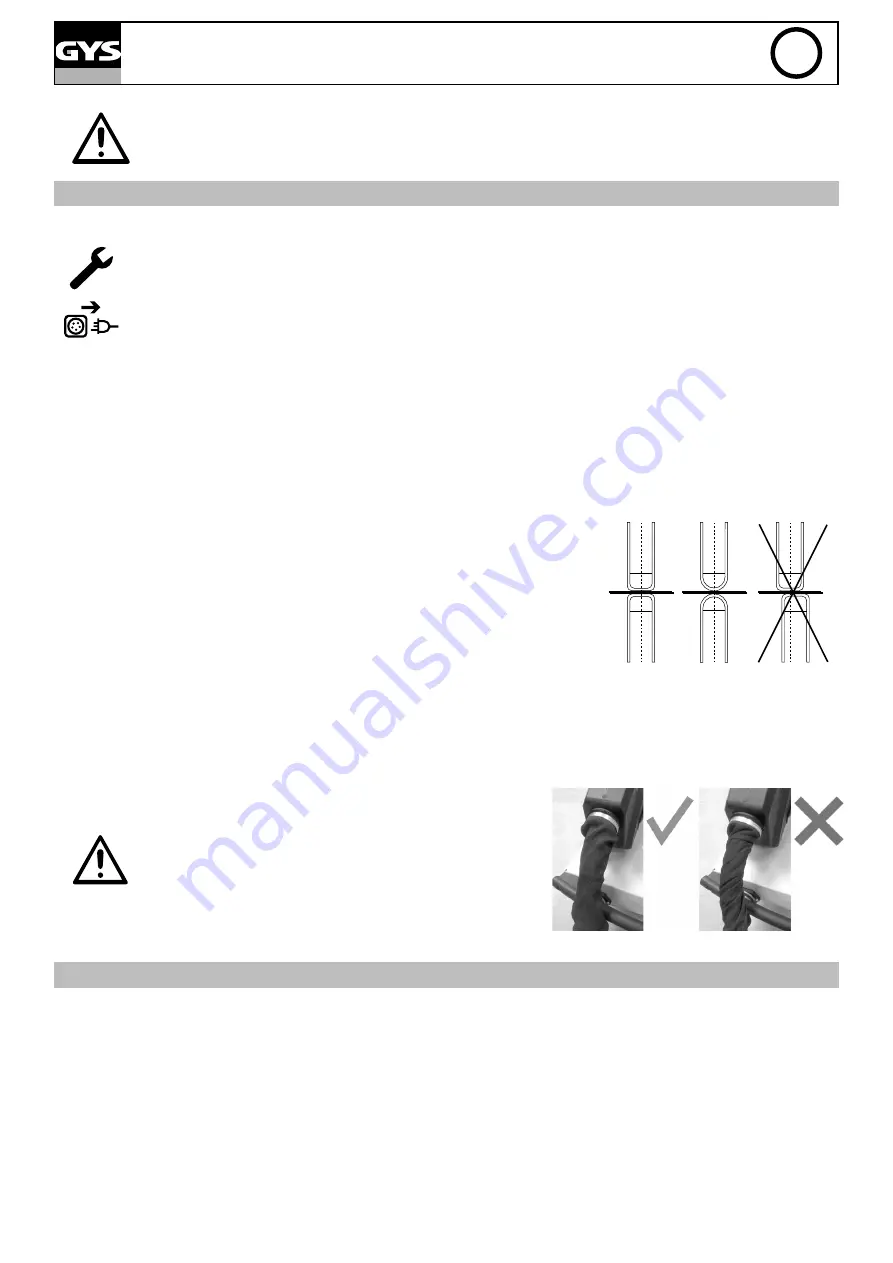

• Prior to using the pneumatic clamp, check the condition of the electrodes/caps (regardless if they are

round or flat). If that is not the case, clean them using sand paper (thin grain) or replace them (see

explanation on the machine).

• To ensure an efficient welding spot, it is necessary to replace the caps every 200 spots. In order to

do so :

- Remove the caps using the caps removing wrench (ref. 050846)

- Fit the caps and apply contact grease (ref. 050440)

• Caps type A (ref : 049987)

• Caps type F (ref : 049970)

• Caps bevelled (ref : 049994)

Warning : the caps must be perfectly aligned. If this is not the case, check the alignment of the

electrodes (cf. chapter «Assembly and replacement of the arms» P. 48)

A

A

F

F

A

A

• Prior to using the gun, check the condition of the different tools (star, single sided electrode, carbon electrode...) and clean or replace if required.

• Remove regularly the casing and any excess of dust. Take this opportunity to have the electrical connections checked by a qualified person, with

an insulated tool.

• Regularly review the condition of the power cable and welding connection cables. In case of visible signs of damage, organise for them to be

replaced by the manufacturer or a qualified technician.

After each use make sure that the harness is not left twisted. A constantly

twisted harness leads to its premature deterioration and can present an

electrical hazard to the user.

• Ensure the vents of the device are not blocked to allow adequate air circulation.

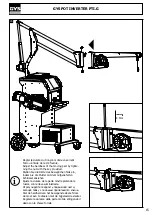

USE OF THE GALLOWS

• The operator must properly fill the coolant canister with coolant before use.

• The use of the bracket is strictly reserved to support the clamp during welding operations.

• Under no circumstances must the jib crane be used as a lifting or other means, as there is a risk of tipping the jib crane trolley assembly.

Summary of Contents for PTI.G

Page 7: ...7 GYSPOT INVERTER PTI G M5 x 12 4 N m 7 8 M8x16 x4 M5x12 x2 20 N m 4 N m...

Page 11: ...11 GYSPOT INVERTER PTI G 12...

Page 17: ...17 GYSPOT INVERTER PTI G FIG 1 FIG 2 3 4 5 1 9 10 11 7 8 6 2 6 7 1 2 3 8 9 5 4...

Page 52: ...118 SAS GYS 1 rue de la Croix des Landes CS 54159 53941 SAINT BERTHEVIN Cedex FRANCE...