58

GYSPOT INVERTER PTI.G

EN

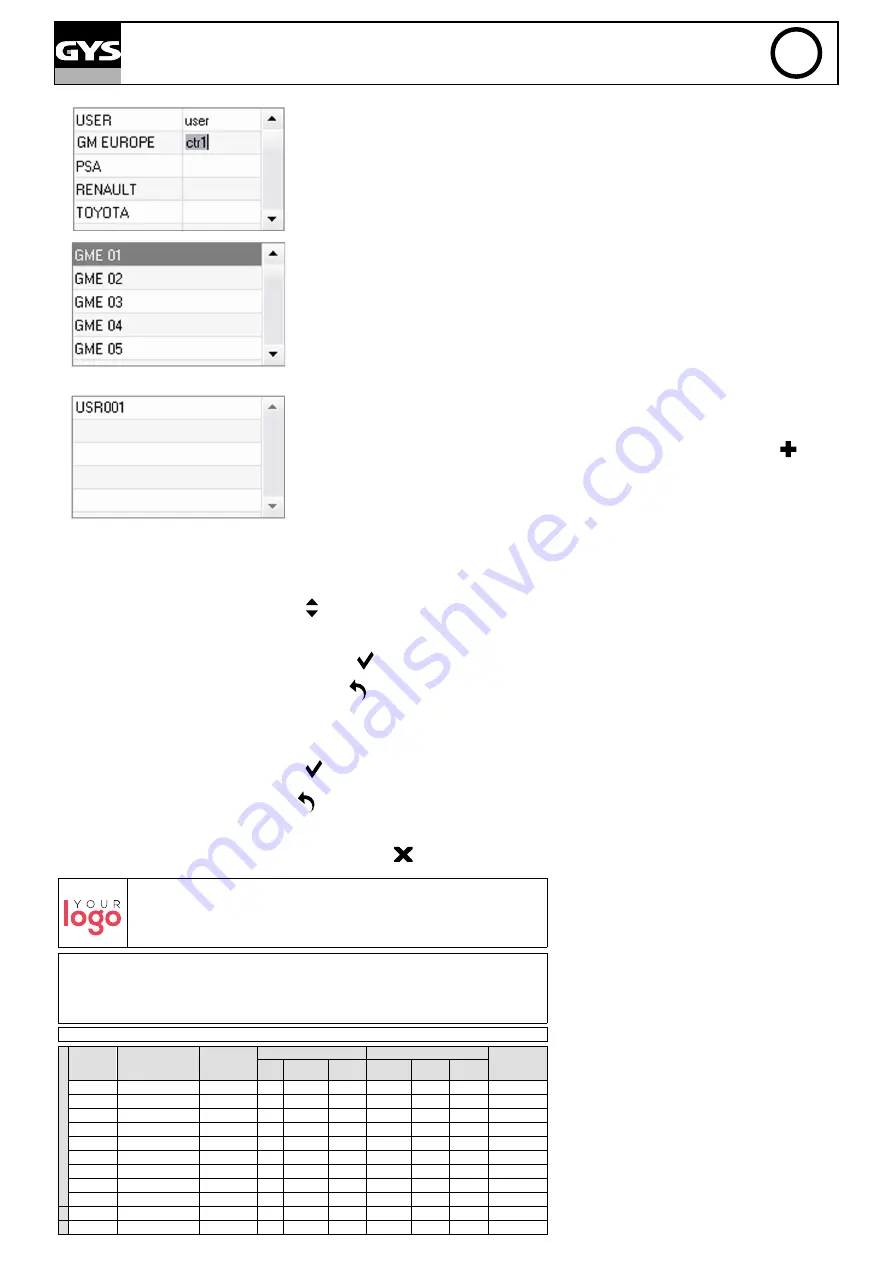

Then double-click in the second column to select a manufacturer file previously downloaded from our

website.

The list of spots set by the manufacturer is displayed in the second list. Select a configured point to

view the chronogram and configured parameters.

4.2 - Add a configured spot in the USER file :

To add a spot to the USER file, select the USER file from the file list and click on the button

to the

right of the list of configured spots. Enter the name of the spot and press the TAB key or click outside

the list of configured spots to configure the welding parameters.

For a spot to be configured, it is possible to configure:

The pre-tightening stage

The pre-heating stage

The different pulses (4 pulses maximum)

And the hot and cold forging stage.

To change the settings, click on the buttons .

When the operator changes a parameter, the spot chronogram is updated.

To validate the spot configuration, click on the button

.

To cancel the spot configuration, click on the button

.

4.3 - Modify a spot configured in the USER file:

To change the settings of a spot, select a spot from the list and then change the welding settings.

To validate the changes, click on the button .

To cancel the changes, click on the button .

4.4 - Delete a configured point in the USER file:

Select a spot parameter from the list and click on the button

to the right of the list.

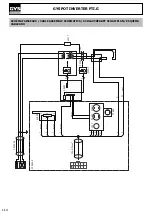

Raison sociale :

Adresse :

Ville :

Code postal :

JBDC

ZI, 134 Bd des Loges

53941

Saint-Berthevin

Email :

contact@companyname.com

www.companyname.com

Site Web :

Téléphone :

Télécopie :

0243510101

0243510102

1450UT53

Immatriculation :

308SW

Modèle :

01/01/2017

Mise en circulation :

AILE ARRIERE

OPERATEUR

Intervenant :

Ordre de réparation :

977AC92

Commentaires

Date du journal :

05/04/2018

Marque :

PEUGEOT

N° châssis :

12365849

Commentaires :

Intervention :

Date

Mode

Outil

Consignes

Temps

(ms) Intensité (kA)

Serrage

(daN)

Mesures

Intensité (kA) Serrage

(daN)

Etat

GYSPOT BP.LG (1712009013)

Epaisseur

(mm)

Id

1

Auto

Pince en C n°1

Point Ok

630

9,4

325

9,4

325

3,5

05/04/18 10:22

2

Auto

Pince en C n°1

Point Ok

630

9,4

325

9,3

325

3,5

05/04/18 10:22

3

Auto

Pince en C n°1

Point Ok

490

8,2

240

8,2

240

2,0

05/04/18 10:22

4

Auto

Pince en C n°1

Point Ok

510

8,3

250

8,2

245

2,1

05/04/18 10:22

5

Auto

Pince en C n°1

Point Ok

510

8,3

250

8,3

245

2,1

05/04/18 10:22

6

Normal

Pince en C n°1

Point Ok

350

7,3

225

7,3

225

-

05/04/18 10:23

7

Normal

Pince en C n°1

Point Ok

350

7,3

225

7,2

225

-

05/04/18 10:23

8

Normal

Pince en C n°1

Point Ok

400

8,1

265

8,0

265

-

05/04/18 10:23

9

Normal

Pince en C n°1

Point Ok

400

8,1

265

8,1

260

-

05/04/18 10:23

10

Normal

Pince en C n°1

Point Ok

400

8,1

265

8,1

270

-

05/04/18 10:23

11

Manuel

Pince en C n°1

Pression faible

400

8,1

510

8,1

440

-

05/04/18 10:23

Summary of Contents for PTI.G

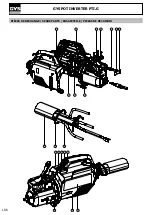

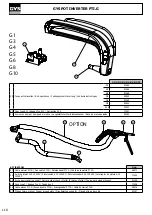

Page 7: ...7 GYSPOT INVERTER PTI G M5 x 12 4 N m 7 8 M8x16 x4 M5x12 x2 20 N m 4 N m...

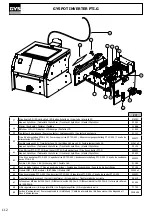

Page 11: ...11 GYSPOT INVERTER PTI G 12...

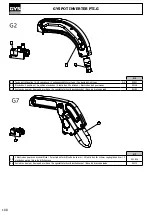

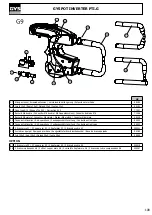

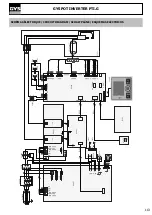

Page 17: ...17 GYSPOT INVERTER PTI G FIG 1 FIG 2 3 4 5 1 9 10 11 7 8 6 2 6 7 1 2 3 8 9 5 4...

Page 52: ...118 SAS GYS 1 rue de la Croix des Landes CS 54159 53941 SAINT BERTHEVIN Cedex FRANCE...