59

GYSPOT INVERTER PTI.G

EN

SAFETY AND MAINTENANCE

User training

People operating this machine must receive suitable training in order to get the most out of the machine capabilities and carry out good quality repairs

(examples: car body work training).

Preparation of the parts to be assembled

It is essential to clean and accost the area to be welded.

In the case of a protective application, make sure that it is conductive by first testing a sample.

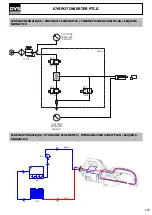

Monopoint electrode welding

When repairing a vehicle, check that the manufacturer allows this type of welding process.

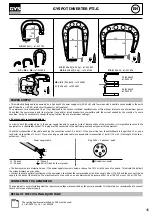

Using the underwing arm

The maximum pressure is 100 daN.

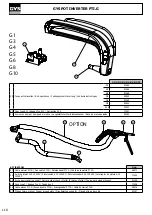

O-rings for the locking nuts of G arm.

Inside the 2 arm locking nuts, there are 2 O-rings that must be replaced in case of a leak or every 6 months. These 2 seals are necessary to avoid

any risk of leakage.

These seals are O-rings d=25, group of 4. When replacing these seals, grease must be applied to them. (ref. 050440 : contact grease)

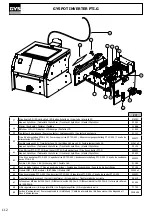

Quantity and quality of the coolant

The coolant level is important for the correct operation of the machine. It must always be between the minimum and maximum level indicated on the

trolley. Top up with demineralized water if necessary.

Replace the coolant every 2 years :

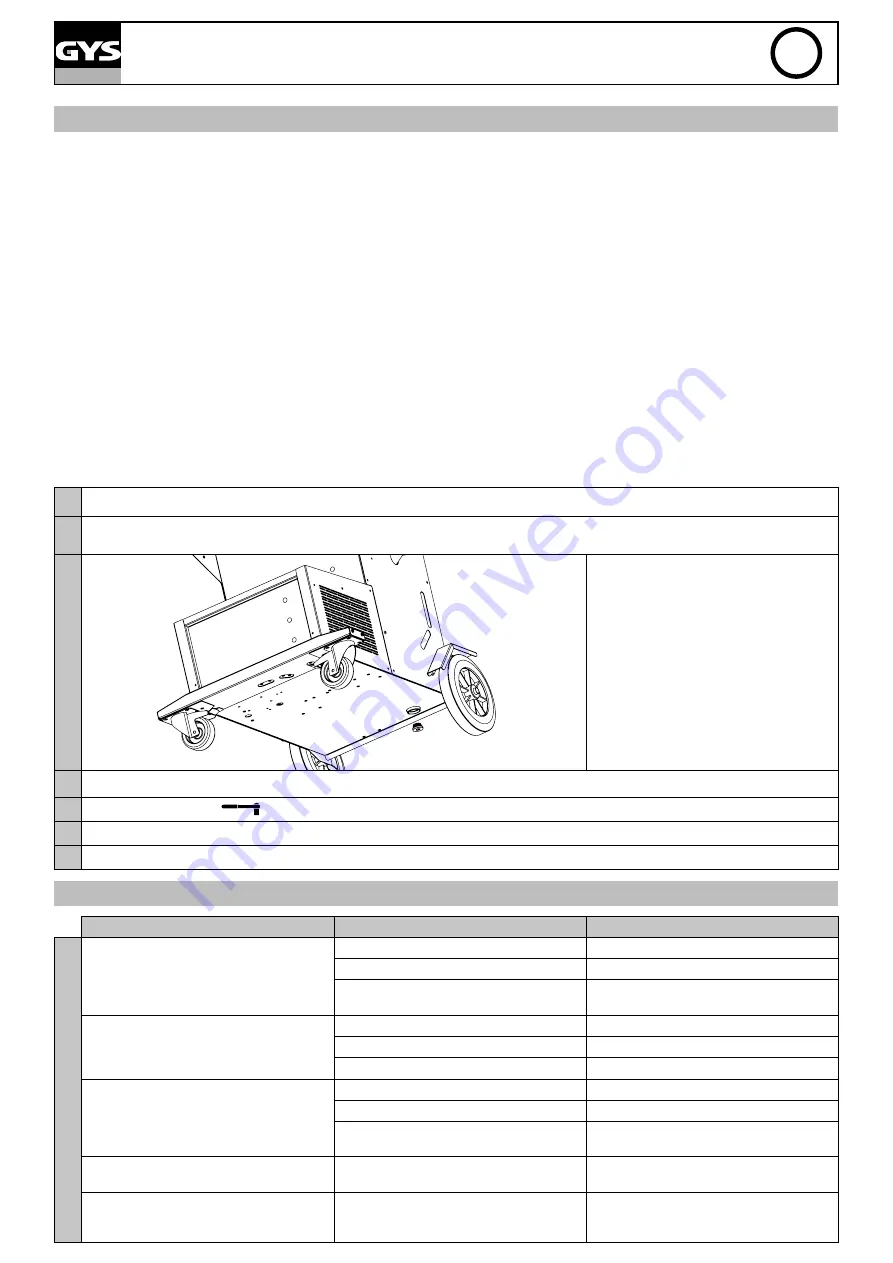

1

Switch off the power supply using the switch located at the rear of the machine (OFF position) and disconnect the unit from the mains.

2 Place a bucket (min. 30 l capacity) under the machine drain hole.

3

Unscrew the drain plug located under the

machine using a 10 mm torx spanner.

(Ref. S6262)

4 Rinse the inside of the tank with running water to remove deposits.

5 Replace the drain plug. (

:

4 N.m)

6 Fill the tank with coolant (5l : 062511 / 10l : 052246)

7 Turn the power back on (ON position) and check for leaks.

TROUBLESHOOTING

TROUBLESHOOTING

CAUSES

SOLUTIONS

Clamp welding

The spot made does not hold or does not

enough

The caps are worn out.

Change the caps.

The sheets are not clean enough.

Check the preparation work.

The arm selected does not match the one

mounted.

Check the arm selected in the software.

The machine makes a hole in the sheet.

The caps are worn out.

Change the caps.

Insufficient air pressure.

Check the air pressure (min. 8 bar)

The surface is not properly prepared.

Prepare/clean the surface to be worked on

Lack of power

Power supply problem.

Check the stability of the mains voltage

Caps blackened or damaged.

Change the caps.

Incorrect arm locking.

Refer to the chapter "Assembly and changing

the arms".

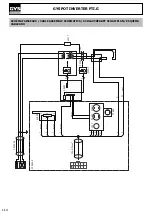

- Fast overheating of the machine.

- Power cable inflation.

No or poor circulation of the coolant.

Open the cart tank cap and observe the

movement of the coolant and correcrt return.

- Pump stopping

- Polluted coolant

- Circuit blocked.

Obstruction in the cooling circuit (pinched

pipe)

Check the sheathing between the trolley.

Check that the pump is working properly.

Check the condition of the coolant.

Summary of Contents for PTI.G

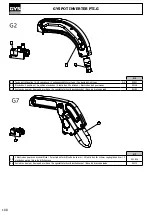

Page 7: ...7 GYSPOT INVERTER PTI G M5 x 12 4 N m 7 8 M8x16 x4 M5x12 x2 20 N m 4 N m...

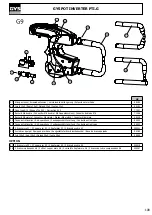

Page 11: ...11 GYSPOT INVERTER PTI G 12...

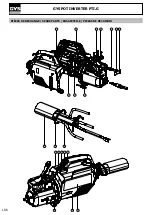

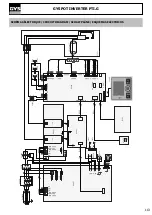

Page 17: ...17 GYSPOT INVERTER PTI G FIG 1 FIG 2 3 4 5 1 9 10 11 7 8 6 2 6 7 1 2 3 8 9 5 4...

Page 52: ...118 SAS GYS 1 rue de la Croix des Landes CS 54159 53941 SAINT BERTHEVIN Cedex FRANCE...