33

TITANIUM 400 AC/DC

EN

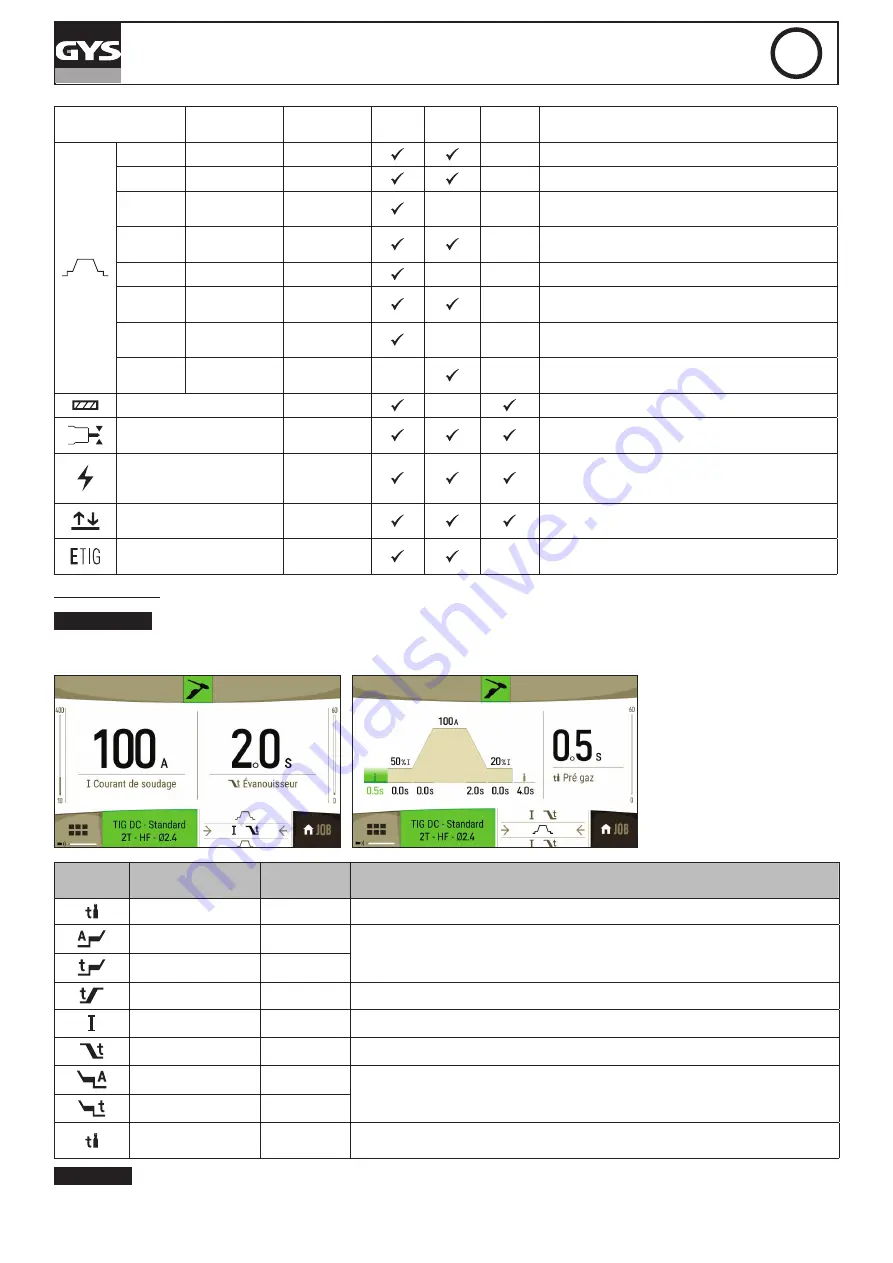

Settings

Designation

Adjustable

settings

TIG DC

TIG AC

TIG

Synergic

Recommendations

Standard

Smooth current

-

-

Pulsed

Pulse current

-

-

Fast

Pulsed

Inaudible

pulsed current

-

-

-

Spot

Smooth poin-

ting

-

-

Tack

Pulse pointing

-

-

-

Multi

SPOT

Repeated

smooth pointing

-

-

Multi TACK Repeated pul

-

sed pointing

-

-

-

AC MIX

Mixing current

AC and DC

-

-

-

Type of materials

Fe, Al, etc.

-

Choice of the material to be welded

Diameter of the Tungsten

electrode

1 - 4 mm

Choice of electrode diameter. Allows to refine HF

priming currents and synergies.

Type of priming

HF - LIFT

Select Starting Function. In ADVANCED display mode,

the HF is adjustable in time [0.01s; 3s] and voltage

indexed from [0;+10].

Trigger mode

2T - 4T -

4TLOG

Choice of trigger welding management mode.

Constant energy welding

ON - OFF

-

Constant energy welding mode with correction of arc

length variations

TIG DC WELDING

TIG DC - Standard

The TIG DC Standard welding process allows high quality welding on most ferrous materials such as steel, stainless steel, but also copper and its

alloys, titanium... The many possibilities of current and gas management allow you to perfectly control your welding operation, from priming to final

cooling of your welding rod.

Settings

Designation

Adjustable

settings

Description & advice

Pre-gas

0 - 60 sec.

Time to purge the torch and to protect the area with gas before ignition

Starting current

10 - 200 %

This starting bearing current is a phase before the current rise ramp.

Starting time

0 - 10 sec.

Rising current

0 - 60 sec.

Current rise ramp.

Welding current

3 - 400 A

Welding current.

Downslope

0 - 60 sec.

Downslope current.

End current

10 - 200%

This stopping stop current is a phase after the current descent ramp.

End duration

0 - 10 sec.

Post-gas

0 - 60 sec.

Duration for which gas is released after the arc has stopped. It protects the weld pool

and the electrode against oxidisation when the metal is cooling down.

TIG DC - Pulse

This pulsed current welding mode is a combination of high current pulses (I, welding pulse) and low current pulses (I_Cold, part cooling pulse).

This pulse mode allows to assemble pieces while while keeping the machine cooler.