30

User manual

WF 35

Translation of the original

instructions

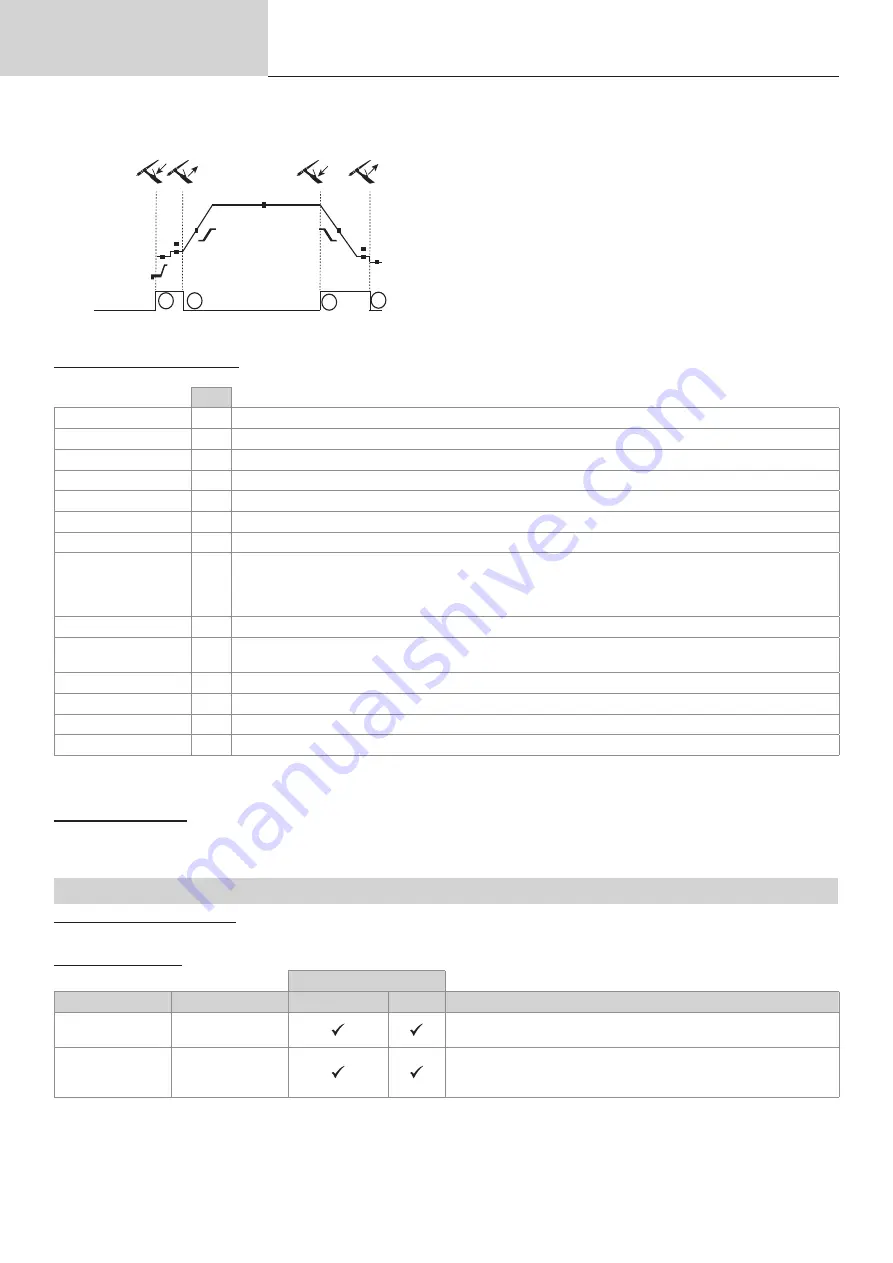

• 4T

t

t

t

t

t

t

T2

T1

Main button

T3

T1

Main button

T2

T4

T3

T1

Main button

T2

T4

>0.5s

<0.5s

<0.5s

T1 - The main button is pressed, the cycle starts from Pre-Gas and

stops at the I_Start phase.

T2 - The main button is released, the cycle continues to upslope

and welding.

T3 - The main button is pressed, the cycle goes to downslope and

stops in the I_Stop phase.

T4 - The main button is released, the cycle ends with the Post-Gas.

NB: for torches, double buttons and double potentiometer

=> «up/weld current» button turns on the potentiometer, the «down»

button turns it off.

For dual button or dual trigger torches, the «high» trigger retains the same functionality as the single trigger torch . The «low» trigger is not active.

CONFIGURING THE SETTINGS

Units

End current

%

This idling current is the next phase after the current is lowered.

Starting current

%

This start-up bearing current is a warm-up phase before the current is raised.

Welding current

A

Welding current.

Cold current

%

Second welding current known as a «cold» welding current.

Pulse duration

s

Manual or time-controlled spot pulse phase

Spot duration

s

Either manual or a set time.

Crater-fill feature

s

Avoids cratering at the end of welding and the risk of cracking, particularly in light alloys.

Frequency

frequency

Hz

Pulse frequency (setting guidelines):

- If welding with manual filler metal, then the F(Hz) is synchronised to the filler action,

- If the metal is thin and without filler (< 0.8mm), F(Hz) > 10Hz

- If welding in position, then F(Hz) < 100Hz

Rising current

s

Allows a gradual increase in welding current.

Post-Gas

s

Duration of the gas protection after the arc is extinguished. It protects the workpiece and the electrode from

oxidation during cooling.

Pre-Gas

s

When the torch is bled and the gas shield is created before ignition.

Stopping time

s

This idling time is a phase that comes after the current is lowered.

Starting time

s

Starting time before the current is raised.

Cold weather

%

Pulsed hot current (I) time balance

Access to some of the welding parameters depends on the selected display mode: Settings/Display mode: Easy or Expert. Refer to the HMI ma

-

nual.

MANUAL GAS PURGE

The presence of oxygen in the torch can lead to a decrease in mechanical quality and can result in less corrosion resistance. To flush the gas from the

torch, press and hold button no. 1 and follow the on-screen procedure. Refer to the HMI manual.

MMA (SMAW) WELDING MODE

INSTALLATION AND GUIDANCE

See power source manual.

PROCESS SETTINGS

Welding processes

Settings

Settings

Standard

Pulsed

Electrode type

Rutile

Basic

The type of electrode determines the settings in order to optimise its

weldability depending on the type of electrode used.

Anti-Sticking

ON-OFF

The anti-stick feature is recommended to safely remove the electrode in

the event of it sticking to the workpiece (the current is cut off automati

-

cally).

Access to some of the welding parameters depends on the selected display mode: Settings/Display mode: Easy or Expert. Refer to the HMI ma

-

nual.