EN

31

User manual

WF 35

Translation of the original

instructions

WELDING PROCESSES

• Standard

This standard MMA welding mode is suitable for most welding applications. It enables welding with all types of coated, rutile, basic and cellulosic

electrodes, as well as on all materials: steel, stainless steel and cast iron.

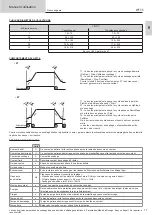

• Pulse

The pulsed MMA welding mode is suitable for upright (PF) applications. The pulsed setting keeps the weld pool cold while promoting material transfer.

Without pulsing, vertical upward welding requires a ‘Christmas tree’ movement, i.e. a difficult triangular movement. Thanks to Pulsed MMA welding,

it is no longer necessary to perform this movement. Depending on the thickness of your workpiece, a straight upward movement should suffice.

However, if you want to enlarge your weld pool, a simple sideways movement similar to downheld welding is sufficient.. In this case, you can set the

frequency of your pulsed current on the display screen. This method offers greater control of the vertical welding operation.

CHOOSING COATED ELECTRODES

• Rutile electrodes: very easy to use in any position.

• Basic electrodes: it can be used in all positions and is suitable for safety work due to its increased mechanical properties.

CONFIGURING THE SETTINGS

Units

Arc Force

Arc Force is an overcurrent administered to prevent sticking when the electrode or weld bead touches the weld

pool.

Welding current

A

The welding current is determined by the type of electrode chosen (see electrode packaging).

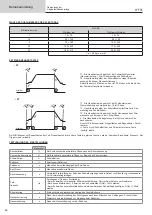

Duration of Hot Start

s

Hot Start is an overcurrent at the ignition stage which prevents the electrode from sticking to the workpiece. The

intensity (% of welding current) and the time (seconds) can be programmed.

Pulse

frequency

Hz

PULSE mode’s PULSING frequency.

Percentage Hot Start

%

Hot Start is an overcurrent at the ignition stage which prevents the electrode from sticking to the workpiece. The

intensity (% of welding current) and the time (seconds) can be programmed.

Percentage I cold

%

Cold weather

s

Access to some of the welding parameters depends on the selected display mode: Settings/Display mode: Easy or Expert. Refer to the HMI ma

-

nual.

ADJUSTING THE WELDING INTENSITY

The following settings correspond to the applicable current range depending on the type and diameter of the electrode used. These ranges are quite

large as they depend on the usage and the welding position.

electrode Ø (mm)

Rutile E6013 (A)

Basic E7018 (A)

1.6

30-60

30-55

2.0

50-70

50-80

2.5

60-100

80-110

3.15

80-150

90-140

4.0

100-200

125-210

5

150-290

200-260

6.3

200-385

220-340

ADJUSTING THE ARC FORCE

It is advisable to set the Arc Force to the middle position (0) to start welding and then adjust it according to the results obtained and individual welding

preferences. Note: The adjustment range of the Arc Force is specific to the type of electrode chosen.

ROLLERS (B) OPTIONAL

Diameter

Reference (x2)

Diameter

Reference (x2)

Steel

Aluminum

Flux-cored wire

ø 0.6/0.8

042353

-

ø 0.9/1.2

042407

ø 0.8/1.0

042360

042377

ø 1.0/1.2

046849

040915