ELECTRO FREEZE Soft Serve Model GEN-5099

185242

25

7.3 Cleaning Instructions

(continued)

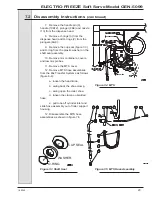

Figure 7-8 Clean beater shaft pin

holes.

e. The beater shafts and the

scraper blade pin holes as shown in figure

7-8.

Important:

Do not leave parts in sanitizer for more

than 15 minutes.

3. After all parts are washed, rinse

and then place them in the sanitizing

solution. Brush the inside of all mix

transfer hoses with sanitizer. For proper

sanitizing, the parts must remain fully

immersed in the sanitizer for 5 minutes.

Allow parts to air-dry after sanitizing.

4. Using a warm dish detergent

solution thoroughly brush; the mix feed

tubes from the refrigerated cabinet to

the cylinders as shown in figure 6-9, the

inside of the cylinders including the back

wall, and the inside of the drain tube, as

shown in figure 7-10.

5. Remove the drip tray and insert.

Wash in a warm dish detergent solution

and rinse with clear water.

6. Wash the outside of the freezer

and inside of the cabinet with a warm dish

detergent solution. Rinse with clear water.

Replace worn

brushes.

Use only Electro

Freeze original

or authorized

replacement parts.

See Accessories

parts list in Part II of

this Manual to order

new brushes.

Figure 7-10 Brush inside of drain

tube.

Figure 7-9

Brush inside of cylinder mix

feed tubes.

Summary of Contents for Electro Freeze GENESIS GEN-5099

Page 2: ......

Page 10: ......

Page 18: ...ELECTRO FREEZE Soft Serve Model GEN 5099 8 185242 4 Part Names and Functions...

Page 74: ......

Page 76: ......

Page 88: ...ELECTRO FREEZE Soft Serve Model GEN 5099 12 185242 Figure 11 Side Back View Breakdown...

Page 94: ......

Page 95: ...ELECTRO FREEZE Soft Serve Model GEN 5099 185242 19 O Ring Chart...