4. Using the supplied housing wrench remove the filter

housing.

5. Discard old filters.

6. Clean filter housings with a cleaning brush

7. Follow sanitizing steps in “Sanitizing the System”

section

8. Install new filters in system.

9. Remove and replace GAC Post filter. Remove fittings

from old post filter, re-apply Teflon tape and install

fittings in new post filter.

10. Turn on feed pressure.

11. Open tank valve.

12. Allow water in tank to flush out post filter and run to

drain until empty. Run 2 more complete batches to

drain before using water.

Membrane Replacement

1. Remove the supply tube from the end of the membrane

housing that has only 1 tube.

2. Unthread the cap from the membrane housing.

3. Remove membrane using a pair of pliers.

4. Clean membrane housing with a brush.

Note:

When installing a new membrane be sure to push

the membrane into the housing as far as it will go.

Each time the filters are replaced it is recommended that

the system be sanitized.

Sanitizing the System

After all filters are removed from the system, housings

have been cleaned, tank is empty, and faucet is open…

1. Add 1 gallon of water to a clean bucket.

2. Add 1 teaspoon of unscented household bleach.

3. Add 1 cup of this solution to each filter housing.

4. Tighten filter housings with solution on RO assembly.

5. Connect membrane housing and feed tube.

6. Open tank valve and feed pressure valve.

7. Allow water to fill the RO housing assembly until water

comes out of faucet.

8. Close the faucet

9. Allow water to run for 5 minutes.

10. Shut-off feed pressure.

11. Allow solution to stand for 30 minutes.

12. Open faucet and allow system to drain.

13. Remove water from housings before installing new

filters and membrane.

14. Install new filters, tighten housings, and reconnect all

tubing connections.

15. Open feed pressure valve and check for leaks.

16. Allow the system to make a full tank of water.

17. Run 2 cycles to drain to rinse out sanitizing solution

before using water.

Troubleshooting

RO Systems are highly sensitive to pressure and

temperature. RO Membranes always perform better under

higher pressures. They produce more water, faster, and

of better quality with high pressure. The vast majority of

problems with RO Systems are a result of low pressure.

The effects of low pressure include water constantly

running to the drain, slow water production and low water

volume available in storage tank. In these cases where low

pressure exists, a booster pump will be required.

On the following page

is a table showing RO Membrane

performance over a range of temperatures and pressures.

Membranes are tested at 65 psi of pressure and

temperature of 77 degrees. For each incremental change

in either variable, membrane performance changes

accordingly. Higher pressures increase production and vice

versa.

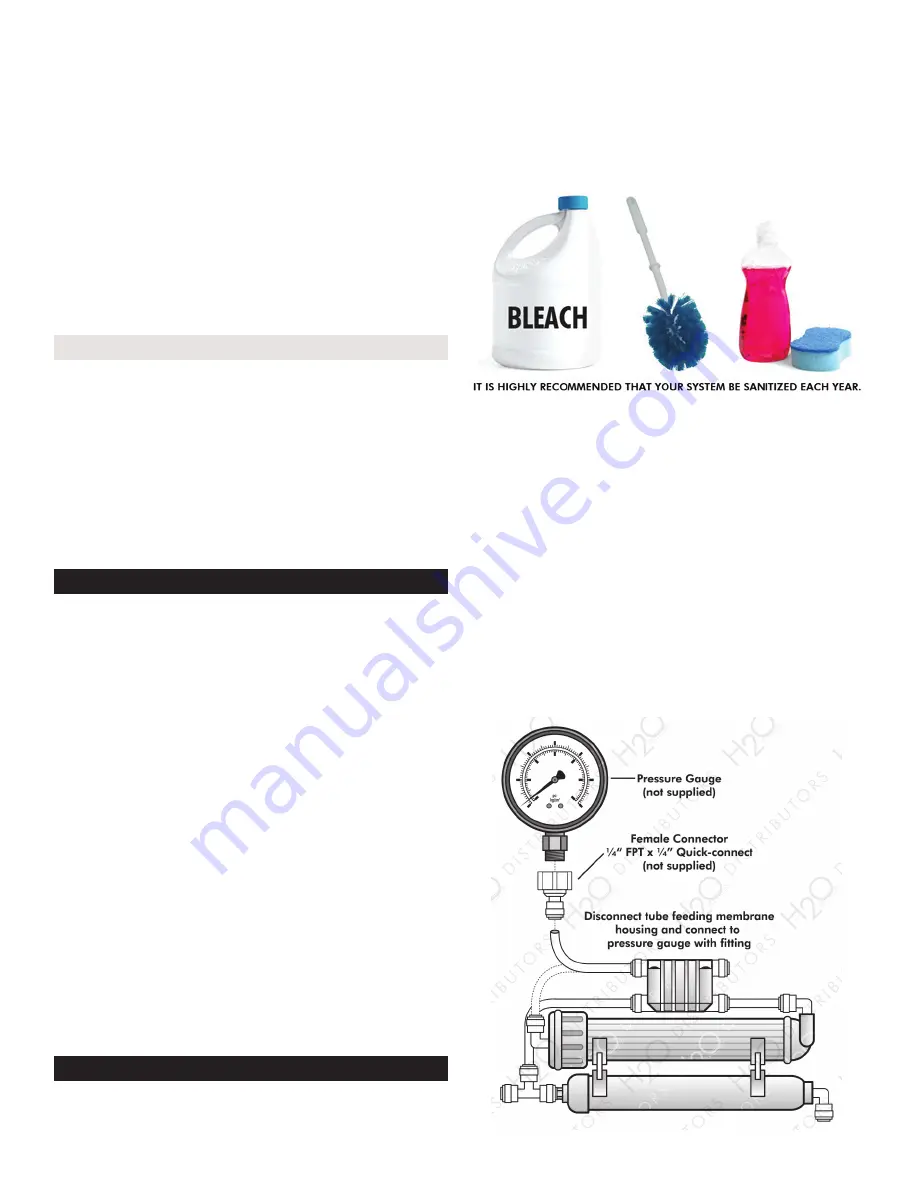

To troubleshoot a poor performing RO System an accurate

measure of the pressure and temperature of water will be

required. This will require a pressure gauge to determine

exactly what the water pressure is that is feeding the

membrane. Descriptions of water pressure such as good,

high or strong, unfortunately, are no help in diagnosing an

RO System.

Summary of Contents for USRO4-100-QC-38

Page 9: ......