2

•

Use the

shutdown

command to disable an interface before you remove a transceiver module

from the interface.

•

Insert a dust cap into any open optical fiber connector and a dust plug into any open fiber port or

transceiver module port to protect them from contamination and ESD damage.

Examining the installation site

The device can only be used indoors. To ensure correct operation and a long lifespan for your device,

install it in an environment that meets the requirements described in the following subsections.

Temperature and humidity

Make sure the temperature and humidity in the equipment room meet the requirements described

in

.

•

Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical

property change of materials, and metal corrosion.

•

Lasting low relative humidity can cause washer contraction and ESD and cause problems

including loose mounting screws and circuit failure.

•

High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the device.

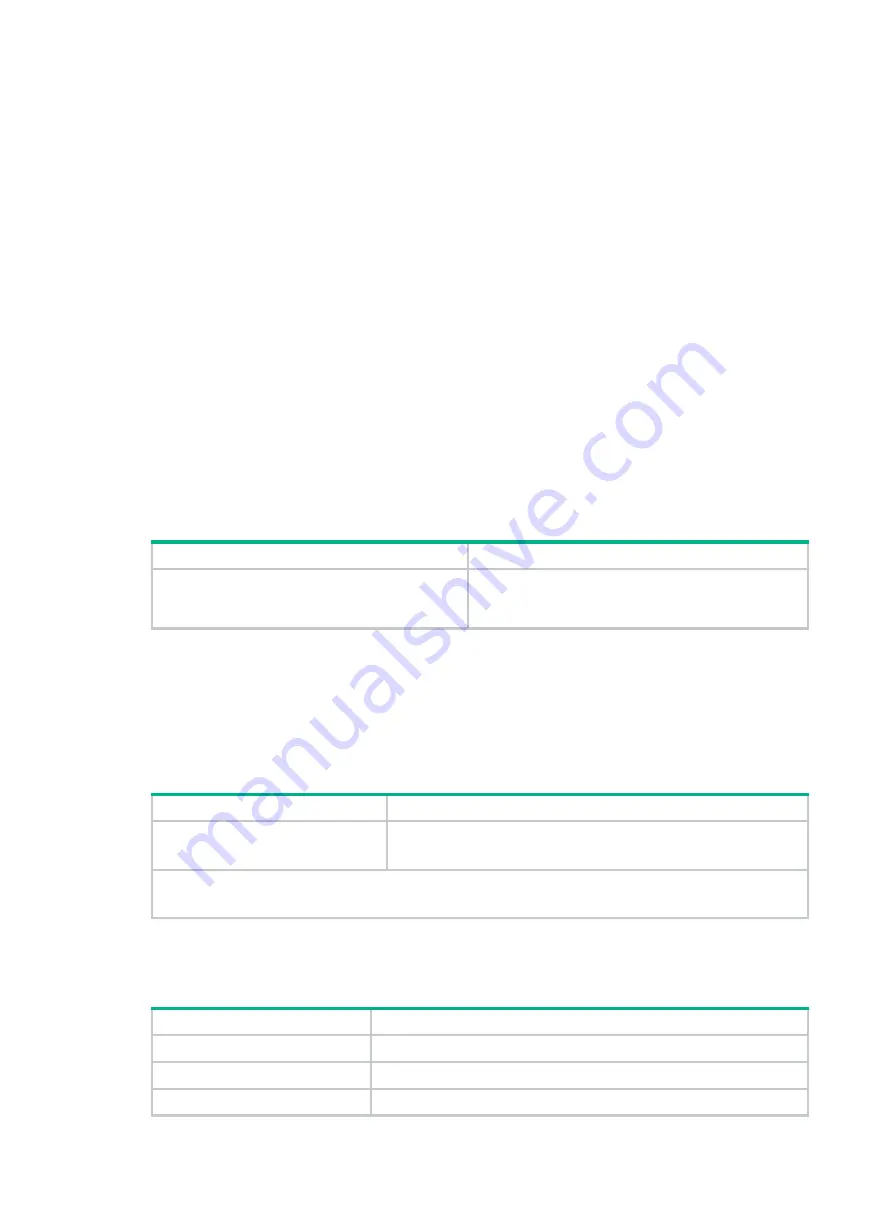

Table 2 Temperature and humidity requirements for the equipment room

Temperature Relative

humidity

•

Without a hard disk: 0°C to 45°C (32°F to

113°F)

•

With a hard disk: 5°C to 40°C (41°F to 104°F)

•

Without a hard disk: 5% to 95%, noncondensing

•

With a hard disk: 10% to 80%, noncondensing

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of

metal components and contact points, especially when indoor relative humidity is low. In the worst

case, electrostatic adsorption can cause communication failure.

Table 3 Dust concentration limit in the equipment room

Substance

Concentration limit (particles/m

3

)

Dust particles

≤

3 x 10

4

(No visible dust on desk in three days)

NOTE:

Dust particle diameter

≥

5 µm

The equipment room must also meet limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in

Table 4 Harmful gas limits in the equipment room

Gas Max.

(mg/m

3

)

SO

2

0.2

H

2

S 0.006

NH

3

0.05