1-3

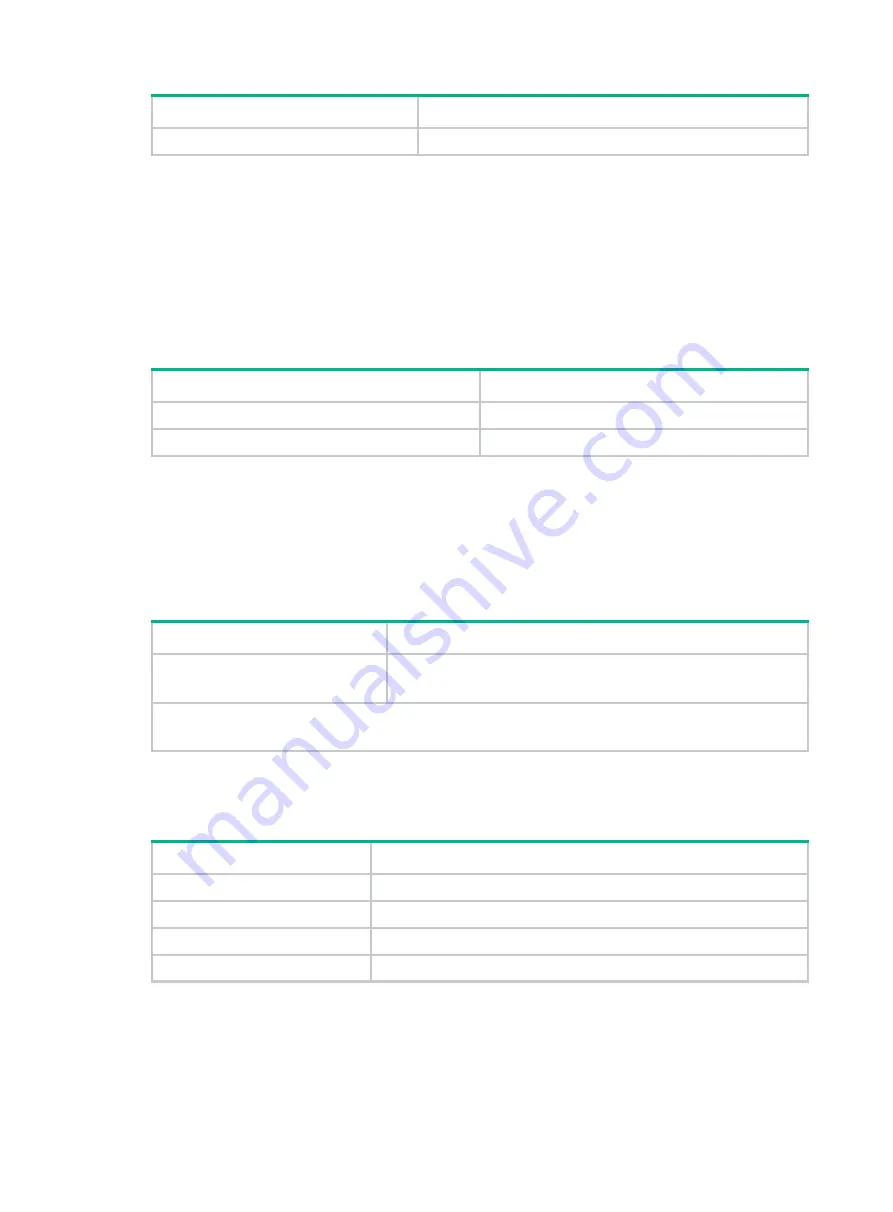

Temperature Range

Storage temperature

–40°C to +70°C (–40°F to +158°F)

Humidity

Maintain appropriate humidity in your equipment room, as described in

•

Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical

property change of materials, and metal corrosion.

•

Lasting low relative humidity can cause washer contraction and ESD and cause problems

including loose mounting screws and circuit failure.

Table 1-2 Humidity requirements

Humidity Range

Operating humidity

5% to 95%, noncondensing

Storage humidity

5% to 95%, noncondensing

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of

metal components and contact points. In the worst case, electrostatic adsorption can cause

communication failure.

Table 1-3 Dust concentration limit in the equipment room

Substance

Concentration limit (particles/m

3

)

Dust particles

≤

3 x 10

4

(No visible dust on desk in three days)

NOTE:

Dust particle diameter

≥

5 µm

The equipment room must also meet limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in

.

Table 1-4 Harmful gas limits in the equipment room

Gas Max.

(mg/m

3

)

SO

2

0.2

H

2

S 0.006

NH

3

0.05

Cl

2

0.01

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the device and application

system, adversely affect the device in the following ways:

•

A conduction pattern of capacitance coupling.