1-6

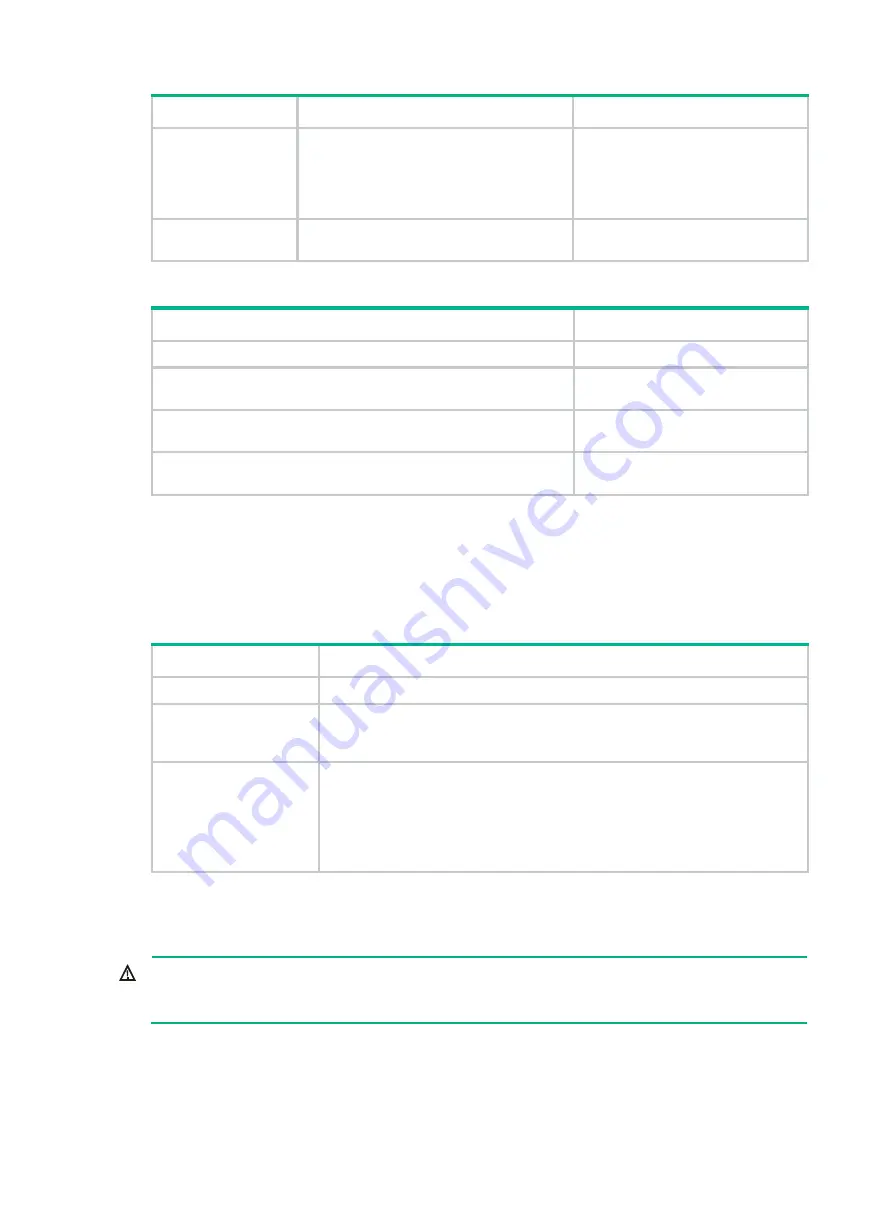

Category

Definition

Example

B2: harsh

environment

•

Unshielded places where the

temperature and humidity are not

controlled.

•

Sea environments or outdoor land

environments near pollution sources.

Islands, ships, and completely

exposed outdoor places near

pollution sources.

C: special

environments

Special application environments

Buried, underwater, or undersea

environments and manholes.

Table1-6 Pollution sources

Category

Radius range

Saline water areas such as oceans and saline lakes

≤ 3.7 km (2.30 miles)

Serious pollution sources such as metallurgic plants, coal mines, and

heat and power plants

≤ 3 km (1.86 miles)

Medium pollution sources such as chemical factories, rubber plants,

and electroplating factories

≤ 2 km (1.24 miles)

Light pollution sources, such as food factories, tanneries, and

heating boilers

≤ 1 km (0.62 miles)

Checking power distribution or power supply

environment

Table1-7 Requirements for power distribution or power supply environment

Item

Requirements

Preparation

The power supply must be available before you install the switch.

Voltage

The voltage provided to the switch must be within the operating voltage range.

For the operating voltage range, see

H3C S1850-X & S1850V2-X & S1850V2-EI

Switch Series Hardware Information and Specifications

.

Power receptacle and

cables

•

If the external power supply system provides an AC power outlet, use a

country-specific AC power cord. Make sure the PE wire of the AC power

supply is grounded reliably.

•

If the external power supply system provides a DC distribution box, prepare

DC power cords yourself.

•

Do not use the power cord provided with the switch on other devices.

Laser safety

WARNING!

Disconnected optical fibers or transceiver modules might emit invisible laser light. Do not stare into

beams or view directly with optical instruments when the switch is operating.

The switch is a Class 1 laser device.