2

Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

•

Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical

property change of materials, and metal corrosion.

•

Lasting low relative humidity can cause washer contraction and ESD and cause problems

including loose mounting screws and circuit failure.

•

High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the switch.

For the temperature and humidity requirements for the switch, see

S6826 & S9826 Switch Series

Hardware Information and Specifications.

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of

metal components and contact points. In the worst case, this might shorten the device's lifetime and

even cause communication failure.

describes the dust concentration limits in the equipment

room.

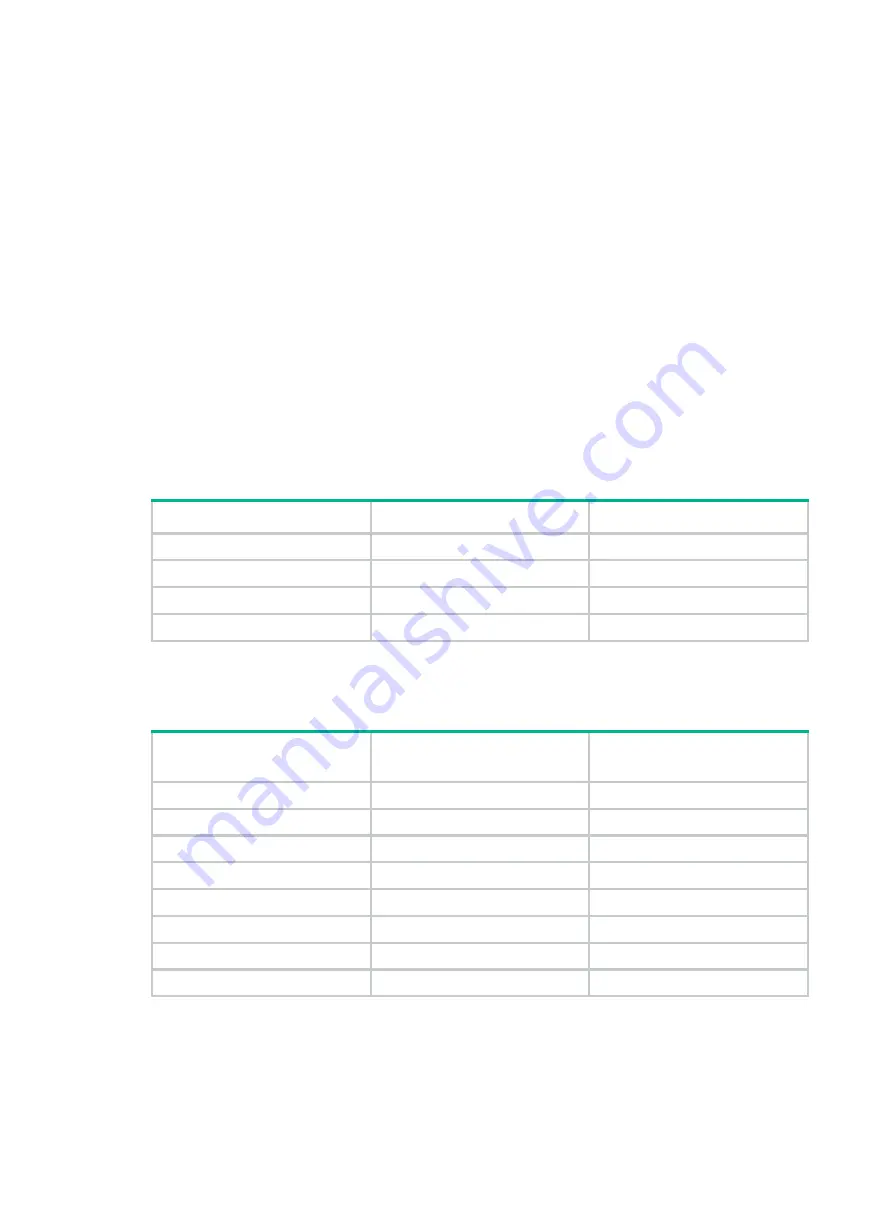

Table1-1 Dust concentration limit in the equipment room

Substance

Particle diameter

Concentration limit

Dust particles

≥ 0.5 µm

≤ 3.5 × 10

6

particles/m

3

Dust particles

≥ 5 µm

≤ 3 × 10

4

particles/m

3

Dust (suspension)

≤ 75 µm

≤ 0.2 mg/m

3

Dust (sedimentation)

75 µm to 150 µm

≤ 1.5 mg/(m

2

h)

Corrosive gases can accelerate corrosion and aging of metal components. Make sure the corrosive

gases in the equipment room do not exceed the concentration limits as shown in

Table1-2 Harmful gas limits in the equipment room

Gas

Average concentration

(mg/m

3

)

Maximum concentration

(mg/m

3

)

SO

2

0.3

1.0

H

2

S

0.1

0.5

Cl

2

0.1

0.3

HCI

0.1

0.5

HF

0.01

0.03

NH

3

1.0

3.0

O

3

0.05

0.1

NO

X

0.5

1.0

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in the following ways: