Installation Manual

H3C SecPath F1000-E Firewall

Chapter 3 Preparing for Installation

3-2

A long-term low relative humidity will result in looseness of fastening screws owing

to shrinkage of insulation washers, or electrostatic discharge (ESD), which may

damage the CMOS circuit on the firewall.

A high temperature will speed up the aging of insulation materials, which greatly

lowers the firewall’s reliability and shortens the service life.

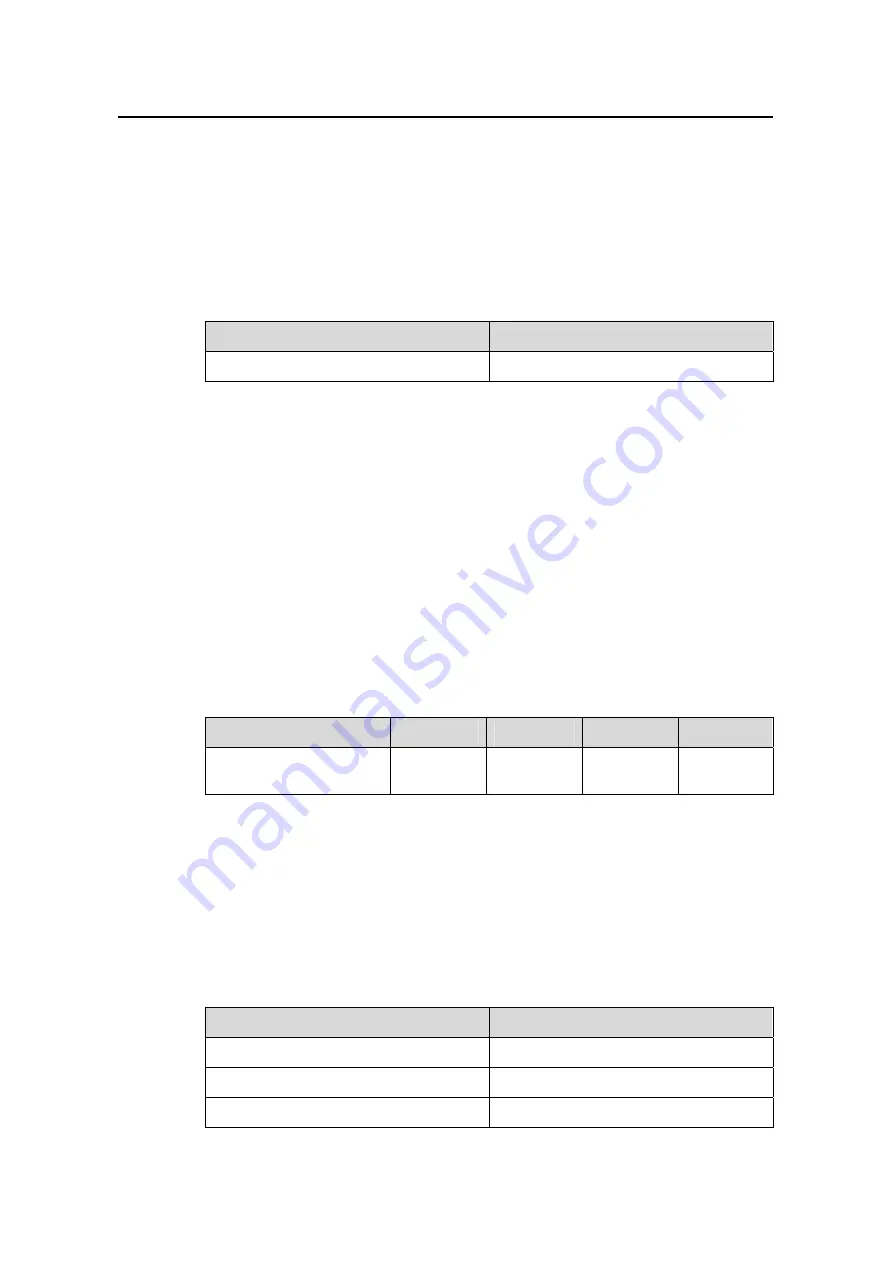

Table 3-1 lists the requirements on temperature and humidity for the F1000-E.

Table 3-1

Temperature and humidity requirements in the equipment room

Temperature

Relative humidity

0°C to 45°C (32°F to 113°F)

10% to 95% (noncondensing)

3.1.3 Cleanness Requirements

I. Concentration limit of dust

Dust is harmful to the safe operation of the firewall. Dust on the chassis may result in

static adsorption, which causes poor contact between metal connectors or joints. The

poor contact may not only shorten the service life of the firewall, but also bring about

communication failures. Especially under the condition of low indoor humidity, dust is

apt to adsorb.

Table 3-2 lists the requirements on the dust concentration and diameters in the

equipment room.

Table 3-2

Limitation on dust concentration and diameter in the equipment room

Diameter (

μ

m)

0.5

1

3

5

Concentration limit

(particles/m³)

1.4×10

7

7×10

5

2.4×10

5

1.3×10

5

II. Concentration limit of harmful gases

Besides, the contents of salts, acids, and sulfides in the equipment room of the firewall

should be strictly restricted. Harmful gases could accelerate the corrosion of metal

parts and the aging of some parts. Table 3-3 lists the concentration limit of SO

2

, H

2

S,

NH

3

, and CI

2

in the equipment room.

Table 3-3

Concentration limit of some harmful gases in the equipment room

Gas

Max (mg/m

3

)

SO

2

0.2

H

2

S 0.006

NH

3

0.05