4

Substance

Concentration limit (particles/m

3

)

NOTE:

Dust particle diameter ≥ 5 µm

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion

and premature aging of components, as shown in

Table1-3 Harmful gas limits in an equipment room

Gas

Max. (mg/m

3

)

SO

2

0.2

H

2

S

0.006

NH

3

0.05

Cl

2

0.01

NO

2

0.04

Cooling system

For adequate cooling of the firewall, follow these guidelines:

•

Install the firewall at the installation site with its airflow direction meeting the ventilation

requirements.

Workbench mounting

—Ensure a minimum clearance of 100 mm (3.94 in) around the air

inlet and outlet vents of the chassis.

19-inch rack mounting

—Ensure a minimum clearance of 80 mm (3.15 in) around the air

inlet and outlet vents of the chassis and a distance of 1U (44.45 mm, or 1.75 in) between the

chassis and other devices.

•

Make sure the installation site has a good cooling system.

The F1005 and F1010 firewalls use passive cooling for heat dissipation.

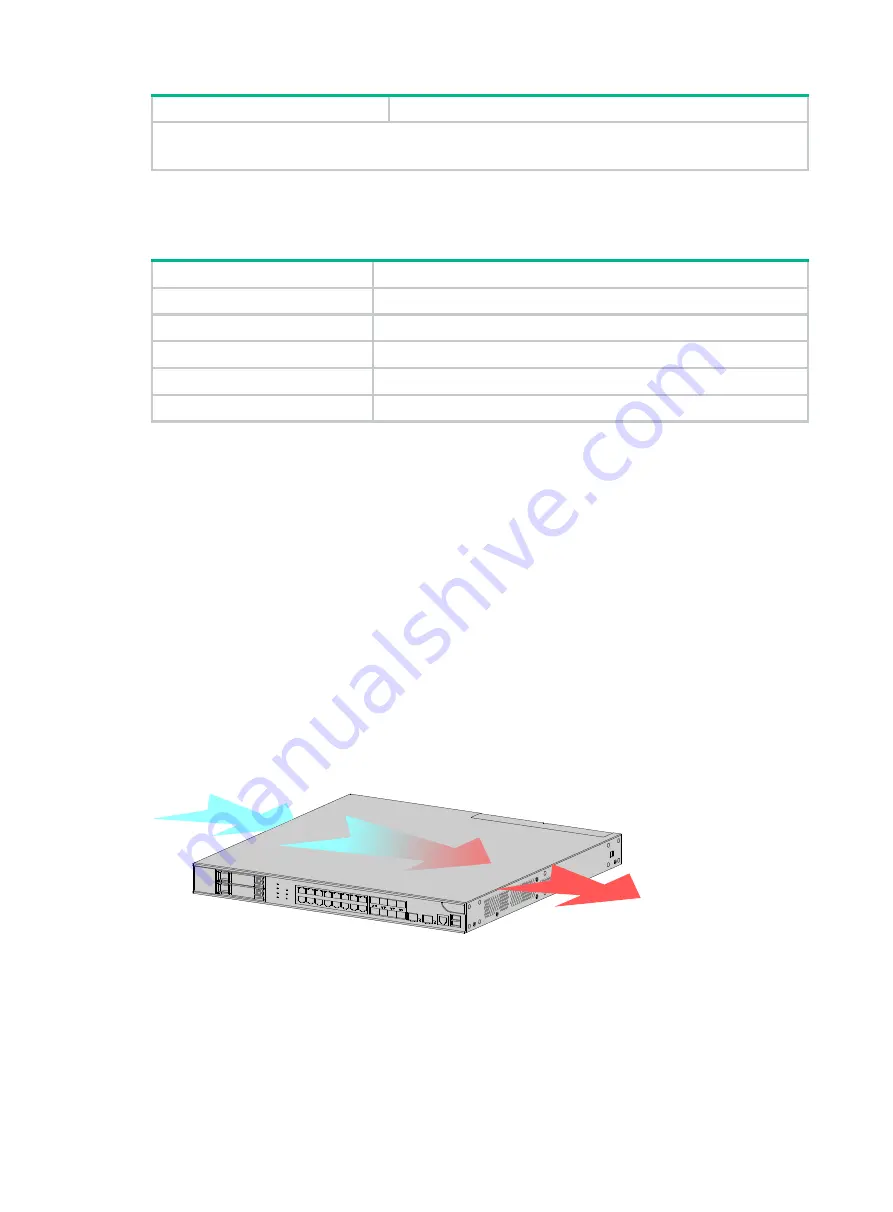

The F1020, F1030, F1050, F1060, F1070, F1080, and F1090 firewalls provide left side-intake and

right-side exhaust airflow for heat dissipation.

Figure1-2 Airflow through the F1080 firewall chassis

ESD prevention

To prevent electrostatic discharge (ESD), follow these guidelines:

•

Make sure the firewall, the workbench, and the rack are reliably grounded.

•

Take dust-proof measures for the equipment room. For more information, see "