094278_t_de_gb_fr_es_it_pt_eseilwi_s

haacon hebetechnik gmbh – T49 (0) 9375 - 84-0 – Fax +49 (0) 9375 - 84-66

27

GB

Inserting the crank interrupts the power supply of the motor.

The appropriate switch has already been connected accor-

ding to the circuit diagram, if a factory control unit is installed.

Otherwise it is the responsibility of the operator to correctly

connect the switching element to the control unit.

The switch is a safety component.

– Examine regularly, however at least once annually, as well

as before commissioning.

The operator must ensure, that the brake is not inad-

vertently vented during normal operation.

e.g. the lever can be unscrewed with 400 V drive units

and screwed in into the crank mounting.

8.5 Drum Release

Drum release only without load!

Only for boat, vehicle salvage, and towing winches;

not permissible for lifting winches!

m

The drum can be separated from

drive unit and brake to remove the

unloaded rope.

z

Move coupling lever (m) toward

the drum.

The coupling is positive locking against independent release.

z

If necessary, turn the drum manually and release coupling.

The rope is not braked when taking off manually. Slack rope

can develop, causing the rope coil to jump of the drum. A pres-

sure roll (Chapter 8.2) can prevent this.

The coupling is equipped with a switch, which interrupts the

power supply of the motor. This switch has already been con-

nected according to the circuit diagram, if a factory control unit

is installed. Otherwise it is the responsibility of the operator to

correctly connect the switching element to the control unit.

The switch is a safety component.

– Check regularly, howeverat least once annually.

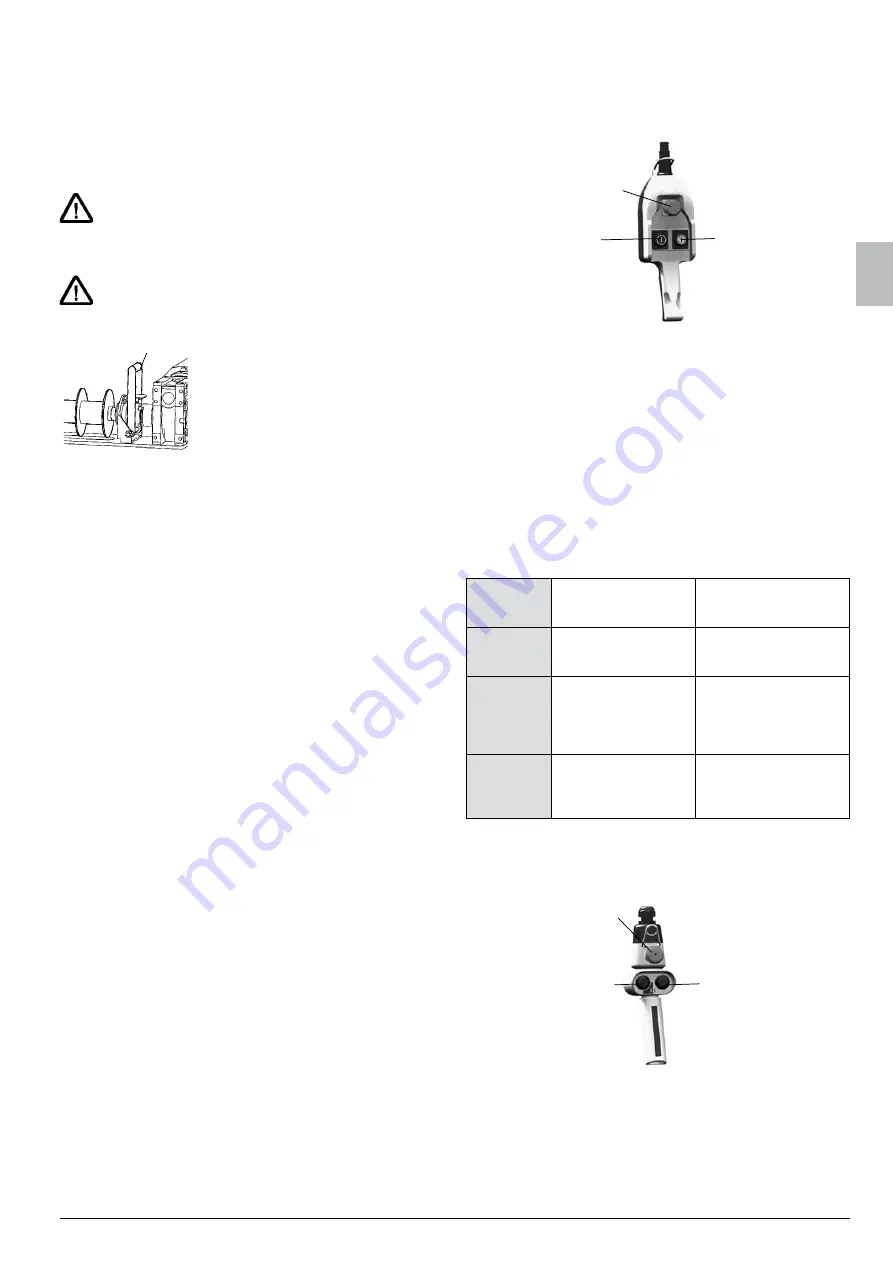

8.6 control with Pendant Pushbutton, direct

The control unit is attached to the gear, if not ordered other-

wise. The motor and a pendant pushbutton (standard supply

line 2 m) are connected to the control unit. The current is con-

ducted via the pendant pushbutton

directly

to the motor.

Emergency stop

Lowering /

unreeling the rope

Lifting /

reeling the rope

8.7 control with Pendant Pushbutton, indirect

The control unit is attached to the gear unit, if it has not

been ordered differently. The motor and, depending on

the equipment, all electrical switches (end position 8.1, slack

rope 8.3, emergency manual 8.4, coupling 8.5) are connected

to the control unit. The power supply to the motor is realised

indirectly

via control circuits.

Pendant pushbutton with control units similar to Chapter 8.6.

Circuit diagram –> Control box. The operator provides the

power supply (–> Chapter 5.1), examines the rotation direction

of the motor and the function of the switches. A warning lamp

(red) on the control box indicates a "malfunction" of normal

operation.

Possible causes:

Emergen-

cy stop

pressed

First release, then conti-

nue working.

Lamp extinguishes

Slack Rrpe

switch actu-

ated

Only „Lifting“ operation

is possible (reeling the

rope).

Lamp extinguishes, as

soon as the rope is tensi-

oned again.

Emergency

hand switch

actuated

Release emergency

hand switch.

As soon as the actuation

of the switch has been

released, the lamp extin-

guishes and continuing

work is possible.

coupling

switch actu-

ated

Engage coupling.

If the switch is no longer

actuated, the lamp extin-

guishes and continuing

work is possible.

The lamp does not light up in the case of disconnection in the

end positions (option 8.1). The device can be however only

driven in the opposite direction.

8.7.1 Operation via pendant push button

Emergency stop

Lowering /

unreeling the rope

Lifting /

reeling the rope