Operating

16

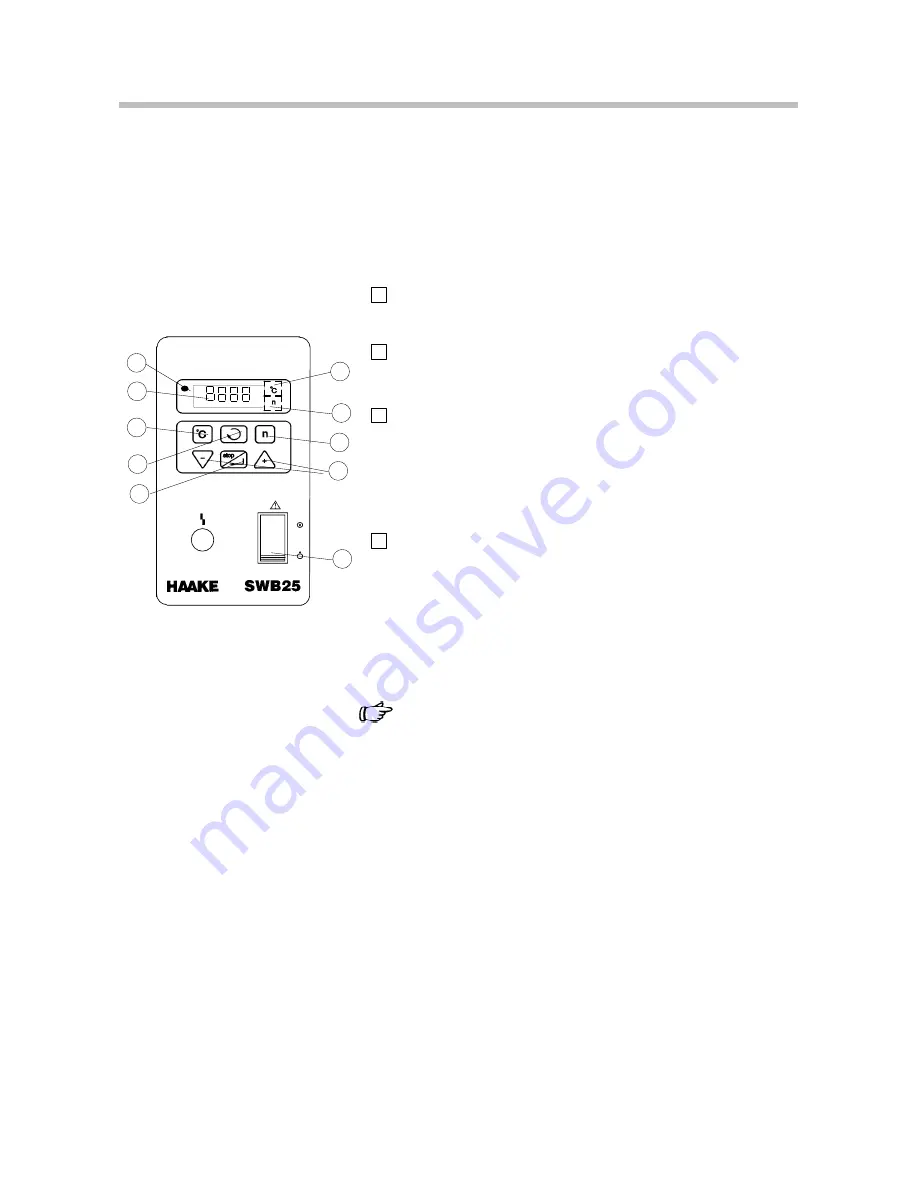

10.6 Adjusting the shaking frequency

Only possible in the speed displaying mode

(Display 17 ”

n

” is lit).

1

Press the menu button 7:

⇒

Small display ”

n

” blinks.

2

Press the shaking frequency button 2:

⇒

Displayed shaking frequency in the display.

3

Increase (+) or decrease (–) the value shown in the dis-

play with the buttons 6.

The first shaking frequency change is thereby passed

slowly and thereafter the rate of shaking frequency

change in the display is five times faster.

4

Press the enter button 8.

⇒

The selected value is stored as new shaking fre-

quency and activated.

⇒

The motor slowly increases the shaking fre-

quency. By pressing the enter button 8 once

again, the actually reached frequency is stored

as new set frequency.

The new value is not saved until the Enter button

has been pressed. The unit continues to use the

old value.

The display 16 automatically switches back to actual sha-

king frequency display after a short time.

16

19

17

18

1

2

6

8

7

3