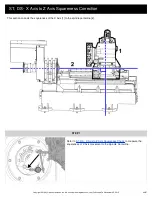

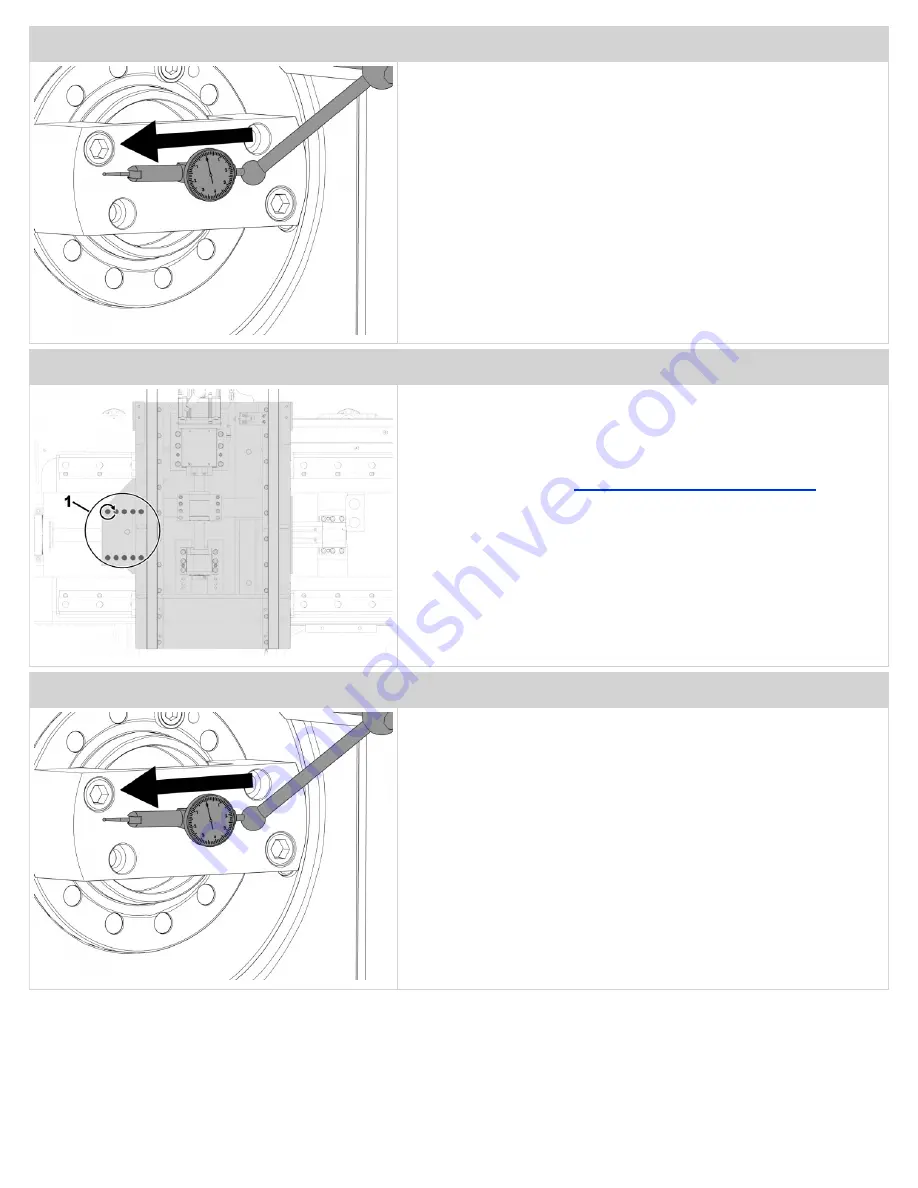

STEP 20

Measure the squareness. If the alignment is not correct, repeat the

previous steps.

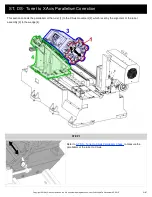

STEP 21

If the alignment is correct, tighten the (10) screws [1] that attach the

wedge to the ballscrew nut housing. Tighten to approximately half of the

specified torque.

For torque values, refer to

Haas Fastener Torque Specifications

.

STEP 22

Measure the squareness.

Copyright 2018 by Haas Automation, Inc. No unauthorized reproduction | Last Published On November 05, 2015

21/67