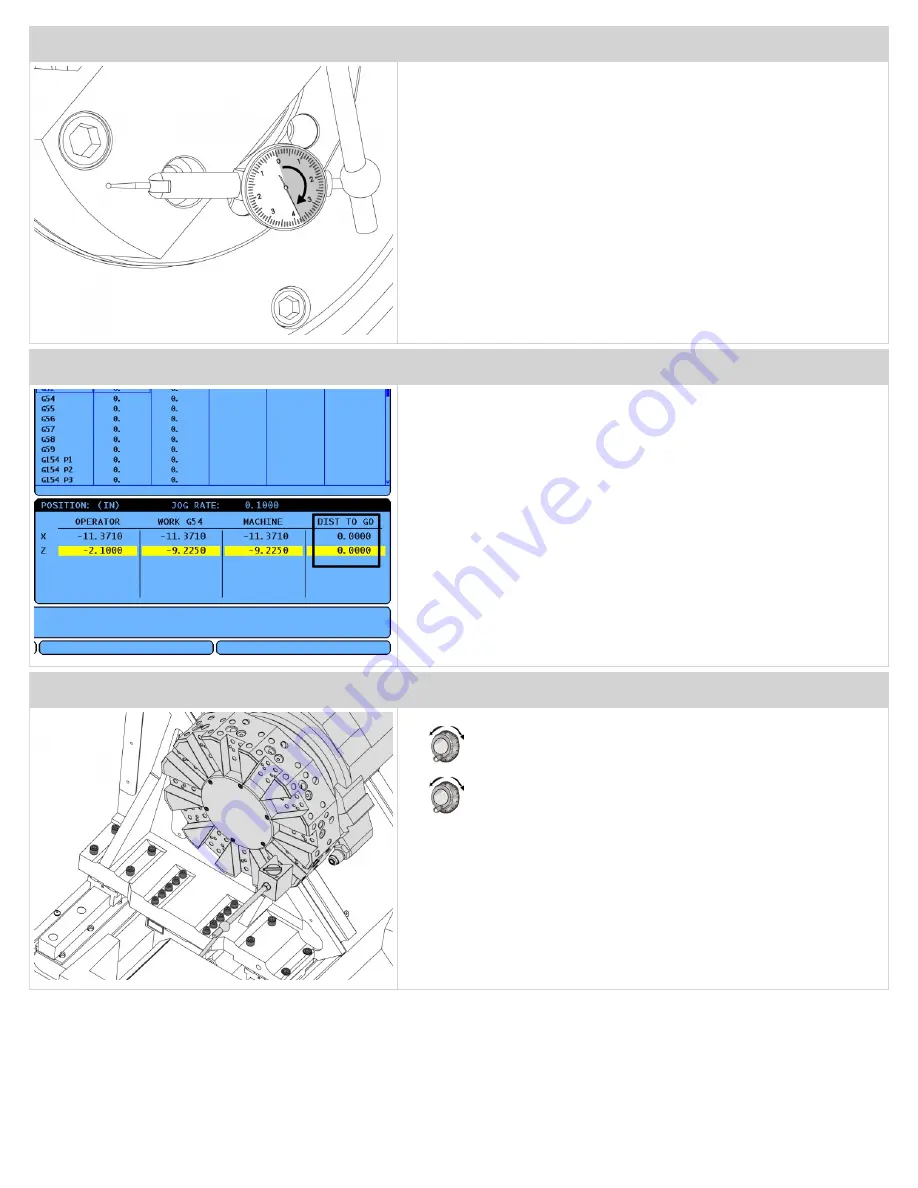

STEP 2

Look at the indicator to see the amount and the direction of the error.

STEP 3

Press

[ZERO RET]

to set the

DIST TO GO

values to 0. Press

[HAND

JOG]

to see the coordinate position display. We will return to this 0

DIST

TO GO

position in the steps that follow.

STEP 4

Jog the Z Axis a small amount to move the indicator away

from the spindle.

Jog the X Axis to move the turret to get access to the screws.

Copyright 2018 by Haas Automation, Inc. No unauthorized reproduction | Last Published On November 05, 2015

24/67