5

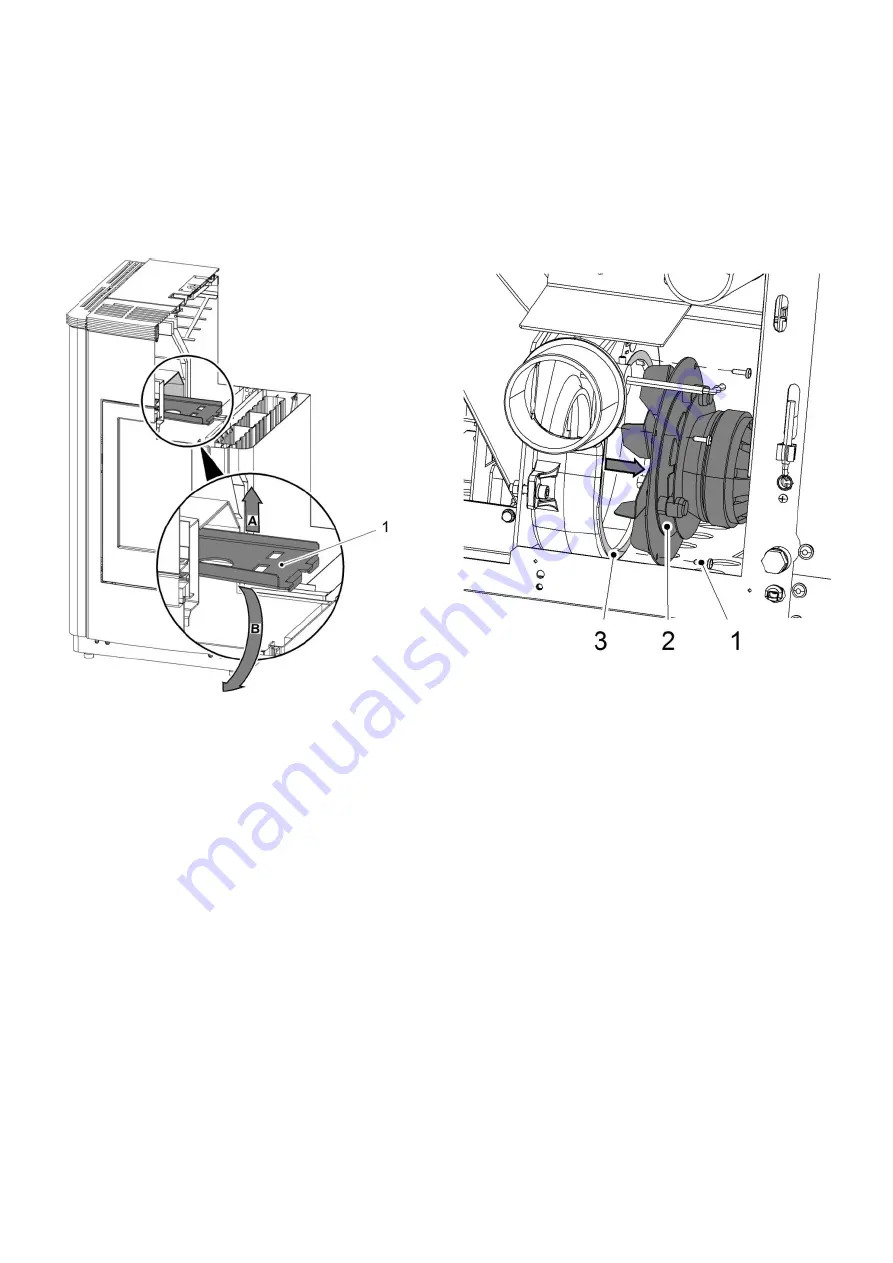

1.6.

Cleaning the flue gas passes - annual

maintenance

First pull the stove away from the wall so as to create

enough room to work at the back.

To clean the flue gas passes, proceed as follows:

Disconnect the flue baffle (1) from the guide by lifting it.

Draw the right cladding (2) down out of the guide and

place it down in the ash space. Then the flue baffle can

be removed and the upper part of the combustion

chamber can be cleaned. (See Figure 4a).

Figure 4a:

Removing the flue baffle

Then remove the right side wall. This is fixed with

screws (1) at the back and at the front with 3 connectors.

Remove the screws from the back and pull the side wall

off sideways. (See Figure 4b).

1.7.

Cleaning the induced draught housing and fan

This housing is made accessible for cleaning by undoing

the 4 nuts shown in Figure 5. (See arrows).

Remove the induced draught motor by pulling it out.

Now clean the flue gas passes, the induced draught fan

and the flue tubes with a brush and an ash vacuum

cleaner.

Then reassemble the components in reverse order.

Make sure that the seal is seated in the right position

again. It is essential to replace defective seals.

Make sure of the electrical connections on the fan motor

and their correct positions.

Figure 5: Induced draught fan

1 = Screw

2 = Blower motor

3 = Seal

Summary of Contents for Pelletto III 419.08

Page 8: ...8 Figure 6 Dimensions of Pelletto III 419 08 Pelletto III 419 08 C ...

Page 9: ...9 Figure 7 Dimensions of Pelletto III 434 08 Pelletto III 434 08 C ...

Page 10: ...10 Figures 8 Replacement parts Pelletto III 419 08 Pelletto III 419 08 C ...

Page 11: ...11 Figures 9 Replacement parts Pelletto III 434 08 Pelletto III 434 08 C ...

Page 13: ...13 4 Circuit diagram ...