30

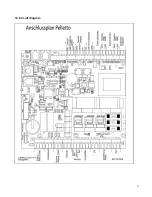

13. Replacement parts list

417.08 417.08-

C 432.08

517.08

Front plate cast iron grey

4

0561008046120

0561008046120

-

-

Front plate anthracite

4

0561008006120

0561008006120

0543208006120

0551708016200

Complete combustion chamber

door cast iron grey

10 0561008045300 0561008045300 0561008045300

-

Complete combustion chamber

door anthracite

10 0561008005300 0561008005300 0561008005300

-

Complete combustion chamber

door black

10 -

-

- 0551708005300

Door

hinge

11 0561008005400 0561008005400 0561008005400 0561008005400

Glass

panel

12 0561008005301 0561008005301 0561008005301 0561008005301

Sealing strip, glass panel 10x4

0040210040005

0040210040005

0040210040005

0040210040005

Sealing strip, combustion chamber

door

0040014140005 0040014140005 0040014140005 0040014140005

Tank cover cast iron grey

1

0561008046190

0561008046190

0561008046190

-

Tank cover anthracite

1

0561008006190

0561008006190

0561008006190

0551708006190

Cover hinge pins

9

0030110500181

0030110500181

0030110500181

0030110500181

Seal, tank cover 1.2 m

3

0089000410005

0089000410005

0089000410005

0089000410005

Side wall left cast iron grey

5

0561008006150

0541708016240

0543208006150

-

Side wall right cast iron grey

6

0561008006145

0541708016140

0543208006140

-

Side wall left anthracite

5

0561008046150

0541708006240

-

-

Side wall right anthracite

6

0561008046145

0541708006140

-

-

Side part ceramic maple

-

0541708006185

-

-

Side part ceramic coffee bean

-

0541708026185

-

-

Blanking panel bottom black

40

-

-

-

0551708016205

Closure frame anth.

41

-

-

-

0551708016160

Combustion pot stainless steel

15

0561008006733

0561008006733

0561008006733

0561008006733

Combustion chamber cladding L.

17

0561008005040

0561008005040

0561008005040

0561008005040

Combustion chamber cladding R.

19

0561008005039

0561008005039

0561008005039

0561008005039

Combustion chamber cladding

back

18 0561008005041 0561008005041 0561008005041 0561008005041

Pellet

chute

20 0561008007401 0561008007401 0561008007401 0561008007401

Draught

baffle

plate

21 0561008005701 0561008005701 0561008005701 0561008005701

Allen key 6 mm

9001700060005

9001700060005

9001700060005

9001700060005

Stand

22 0561008006941 0561008006941 0561008006941 0561008006941

Mains cable

0089500380005

0089500380005

0089500380005

0089500380005

Device plug with master switch

23

0089500110005

0089500110005

0089500110005

0089500110005

Main cable set

Cable set, screw conveyor motor

0089500620006 0089500620006 0089500620006 0089500620006

Ignition 350 W

25

0561008005202

0561008005202

0561008005202

0561008005202

OC

24 0089500080005 0089500080005 0089500080005 0089500080005

Induced draught fan

26

0561008005807

0561008005807

0561008005807

0561008005807

Condenser, screw conveyor motor

Screw conveyor motor

27

0089500000006

0089500000006

0089500000006

0089500000006

Screw

conveyor

28 0561008007090 0561008007090 0561008007090 0561008007090

Lower screw conveyor bearing

30

0561008007047

0561008007047

0561008007047

0561008007047

Motor

plate

29 0561008007081 0561008007081 0561008007081 0561008007081

Bottom temperature sensor

31 0561008005543 0561008005543 0561008005543 0561008005543

Flame temperature sensor

32

0561008005541

0561008005541

0561008005541

0561008005541

Flue gas thermosensor

33 0561008005540 0561008005540 0561008005540 0561008005540

Room temperature sensor

34

0089500390005

0089500390005

0089500390005

0089500390005

Door contact switch

35

0561008006510

0561008006510

0561008006510

0561008006510

Plug

set

Connection cable central

unit/operator console

Complete control unit

36

0561008005560

0561008005560

0561008005560

0561008005560

Operator console

8

0561008005510

0561008005510

0561008005510

0561008005510

Backup

battery

37

Fuse T 0,315 A

Fuse T 3,15 A

Complete seal set

0561008006030

0561008006030

0561008006030

0561008006030

Seal set for cleaning openings

0561008006041

0561008006041

0561008006041

0561008006041

Heat exchanger

38 0561008007072 0561008007072 0561008007072 0561008007072

Back

wall

39 0561008006109 0561008006109 0543208006109 0551708006109