GB

8

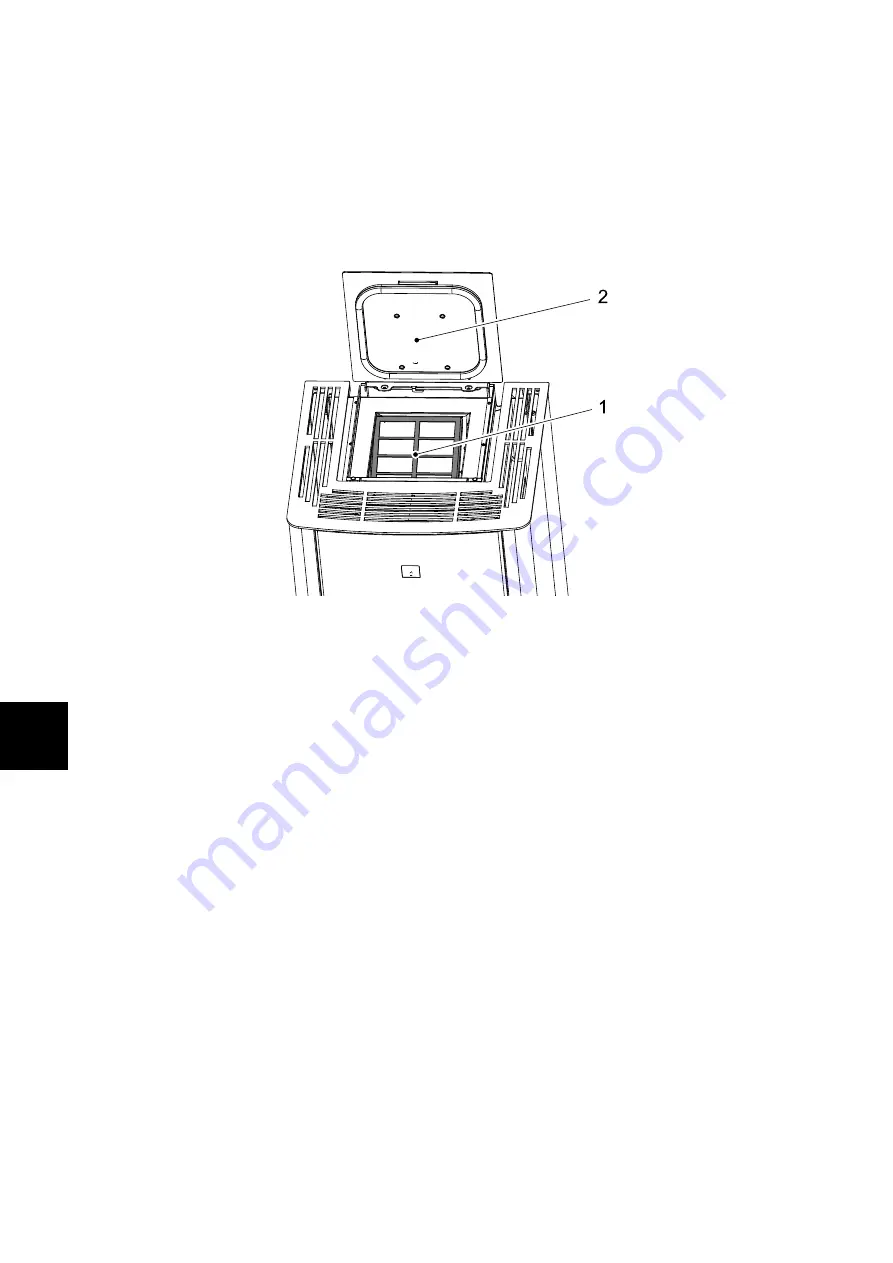

4.2. Cleaning the pellet container - annual maintenance

• Heat the pellet stove until the storage tank is completely empty.

• Then the protective grille (1) in the pellet tank may be removed.

• Then clean the tank and the intake of the screw conveyor housing with a vacuum cleaner.

• After cleaning, it is essential to put back the protective grille. When doing this, make sure that no screws fall

into the pellet tank so as to avoid consequential damage to the screw conveyor.

Figure 3: Pellet tank

1 Protective grille

2 Tank cover

Summary of Contents for HSP 6 Pelletto-IV 419.08

Page 4: ......

Page 10: ...Maintenance work GB 6 Figure 1 Removing the flue baffle...

Page 18: ...Circuit diagram GB 14 6 Circuit diagram Circuit diagram IO 33 3...

Page 20: ......