Summary of Contents for HSP 7 Diana 450.08

Page 4: ......

Page 6: ...Dimensions GB 2 2 Dimensions ...

Page 10: ...Maintenance work GB 6 Figure 1 Removing the flue baffle ...

Page 11: ...Maintenance work GB 7 Figure 2 Removing the cleaning cover ...

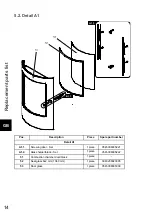

Page 12: ...Maintenance work GB 8 Figure 3 Removing the side wall ...

Page 19: ...Circuit diagram GB 15 6 Circuit diagram Circuit diagram IO 33 3 ...

Page 21: ......

Page 22: ......

Page 23: ......