10

Figure 18:

Burner with burner rings

1 - 6

Combustion air hole rows

7

Oil inlet

8

Bead

9

Lower burner ring

10

Support pin

11

Upper burner ring

Also ascertain the correct seat of the draught deflection

(see Figures 1 + 2). This is usually inserted already at

the factory but may come loose from the suspension

due to transport vibrations. It must also be correctly re-

installed after cleaning and maintenance operations.

A primary-air limiter (PAL, see Figure 19) is installed in

your oil stove, which compensates delivery pressures

above 20 Pa so that economical heating is possible

also with high delivery pressure (chimney draught).

Please check the perfect operation of the PAL or

draught limiter. To this end observe the instructions in

Chapter 12.3 “Maintenance of primary air limiter”.

Bottom

Figure 19: Primary air limiter (PAL)

1

Primary air limiter

2

Pendulum flap

During initial start-up the oil stove must be heated

carefully, i.e. the output controller should be set to 2 to

3 during the first hour, after which normal heating can

commence. The materials of your new oil stove must

get slowly used to the heat development. Through

careful initial heating you will avoid damages to paint

and distortion of material. Possible development of

smell through post-drying of the protective painting will

disappear after a short time. Thoroughly air the rooms

during the paint curing time several times.

Open the tank shut-off valve 2 to 3 turns anti-

clockwise. If the appliance is connected to a central oil

supply, open the quick closing valve (90° turn).

Important:

Before starting your appliance for the first

time you will have to

lift

the

safety lever

(controller

latch) of the oil controller (make: TOBY DVR, see

Figure 20), after which the lever will drop automatically.

This will enable the oil to flow from the oil tank or from

the central oil supply to the oil controller.

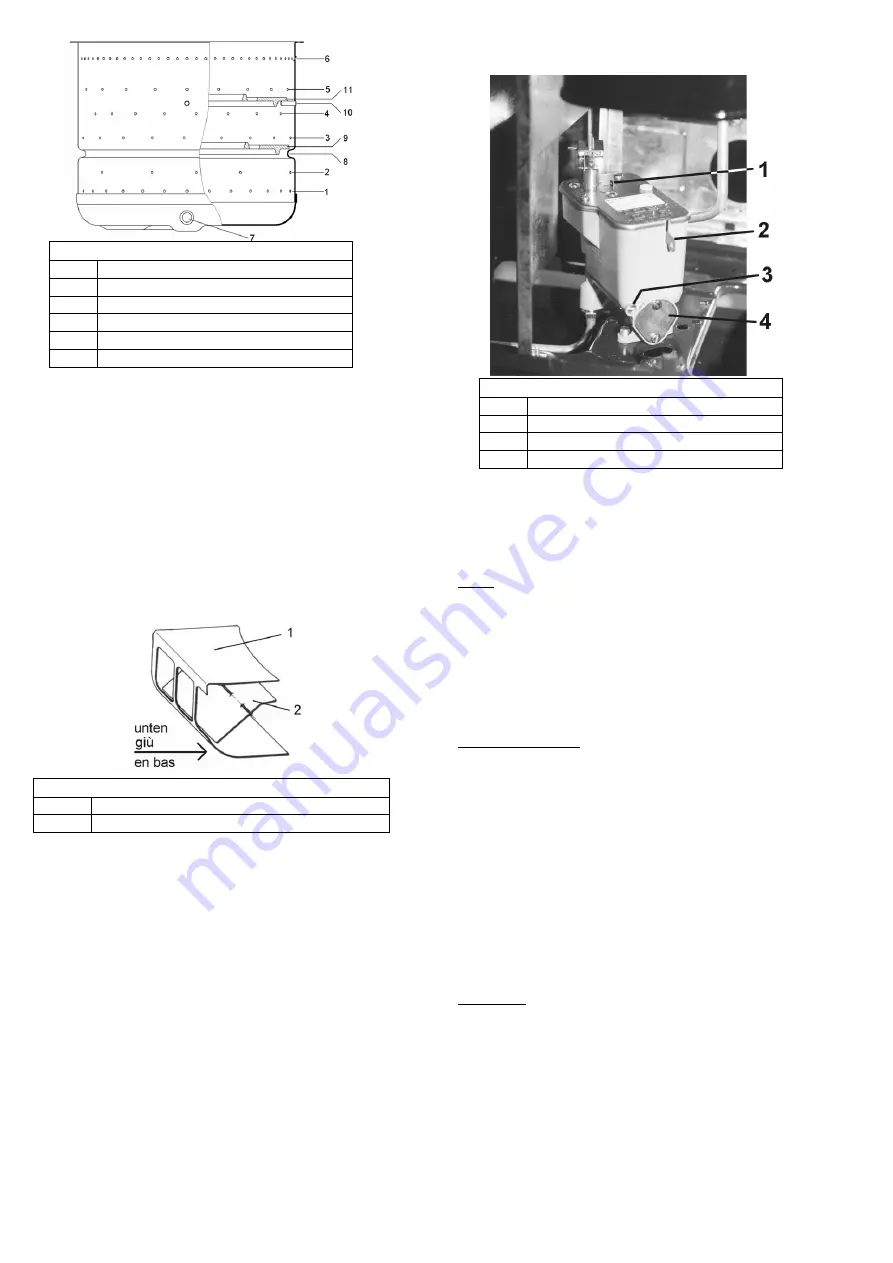

Figure 20:

Oil controller

1

Control pin

2

Safety lever (controller latch)

3

Oil drain plug

4

Filter cover with seal

When igniting during initial start-up, oil controller and

lines must first be allowed to fill with oil. This takes

approximately 3 minutes. With each subsequent start-

up, oil will flow into the burner even after approximately

10

– 15 seconds.

Note: With a new appliance, wax strips are better

suited for lighting than liquid oil stove igniters since the

surface of the burner insert base is still very smooth.

After several starts, fine crusts will form at the base

which increase the surface area, improving oil

evaporation in the burner. At that stage you can start

using liquid oil stove igniters without restriction.

11.4. Igniting and normal operating mode

Note at all times: If the appliance has already been

heated, the oil stove must only be started up again

when the burner insert has cooled down (hand warm).

Otherwise there is a risk of a detonation with additional

consequential damages.

1.

Turn output controller anti-clockwise to position

“6” by overcoming slight noticeable resistance.

On appliances with electric ignition, this serves

to automatically activate the latter. When oil

enters the burner, immediately turn output

controller to position “1”. The marking next to

the output controller indicates the set output

stage.

CAUTION

: Do not allow the burner to be flooded!

Please ensure that only a small amount of oil is in the

burner pot when igniting. If there is a larger amount of

oil in the burner, you will have to absorb the oil for

instance using an entire roll of toilet paper since the

burner base must only be wet but not flooded. A

flooded burner must not be ignited!

2.

On appliances without electric ignition the oil

can now be lit by means of bent wax strips,