12

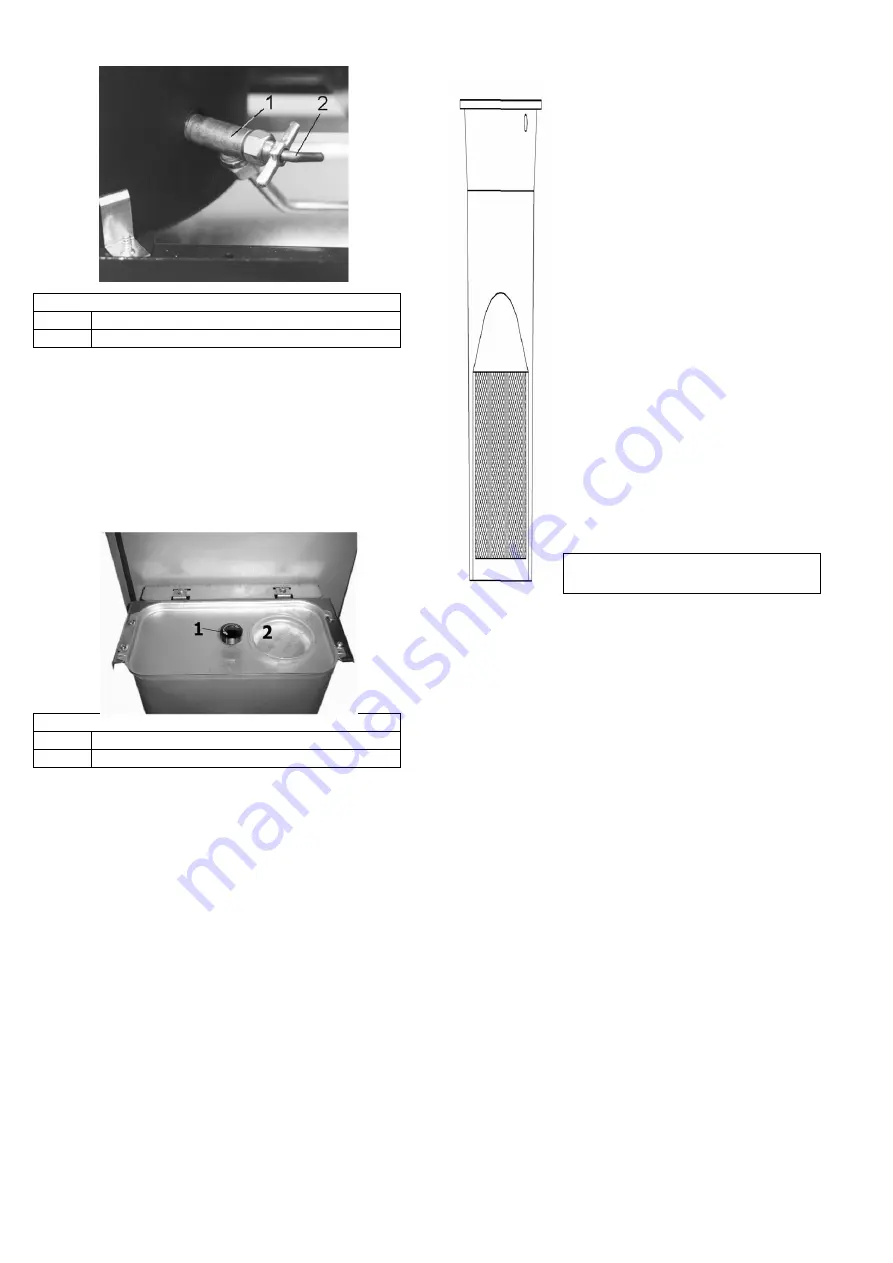

Figure 23:

Plastic filter

Figure 21

1

Inlet spigot

2

Cleaning crank

12.2. Cleaning the oil-carrying parts

Before working on the oil controller (make: TOBY DVR)

it is always necessary to close the tank shut-off valve

(see Figure 22) or, with central oil supply, the quick

closing valve before the stove! You can either place a

shallow vessel under the oil controller for collecting the

oil or allow the oil to drain into the existing oil pan.

Dirt in the oil controller can be removed as follows:

Figure 22: Oil tank

1

Tank shut-off valve

2

Tank insert lid

1. Remove filter cover on the oil controller (2 screws)

and remove filter seal and collect oil (Figure 20).

2. Remove plastic filter and immerse in hot water

(max. 60°C

– do not use boiling water!), for several

minutes, clean with a brush if required. Please do

not use paraffin or petrol for cleaning the filter since

residue containing paraffin in the strainer can only

be removed with hot water.

3. Shake the filter and allow to dry.

4. Slide the filter back into the controller and reattach

the filter seal and the filter cover using the two

screws.

5. Re-establish the oil supply to the oil controller:

open either the tank shut-off valve or, with central

oil supply, the quick closing valve.

Remove water in the heating appliance as follows:

1. Drain oil from the oil controller by opening the drain

plug and the filter cover.

2. Unscrew connection line from the oil controller to

the burner (open-end wrench 14 and 17) and drain.

When installing the oil line, ensure that the screw

connections are tightened carefully without excessive

force to avoid damaging the threads resulting in leaks.

3. With water in the tank, keep the

tank shut-off valve open with opened

filter cover until pure fuel oil runs out.

In rare cases it may happen that the

dosing bar in the oil controller becomes

dirty, obstructing or even entirely

interrupting the oil flow. If applicable,

this can be rectified as follows: Set

output controller to maximum position

“6” and vigorously tap on the control

pin on the oil controller cover (see

Figure 20). After this, turn the output

controller back to “0”.

You might have to push the safety

lever (controller latch) of the oil

controller up (see Figure 20) to release

the oil supply to the controller (see

Chapter 11.3.).

You should also clean the filter in the

filler neck of the tank from time to time

(see Figures 22 + 23). To do so, simply

remove the tank lid and remove the

filter. After this, proceed as described

in paragraph 2. Cleaning the plastic

filter.