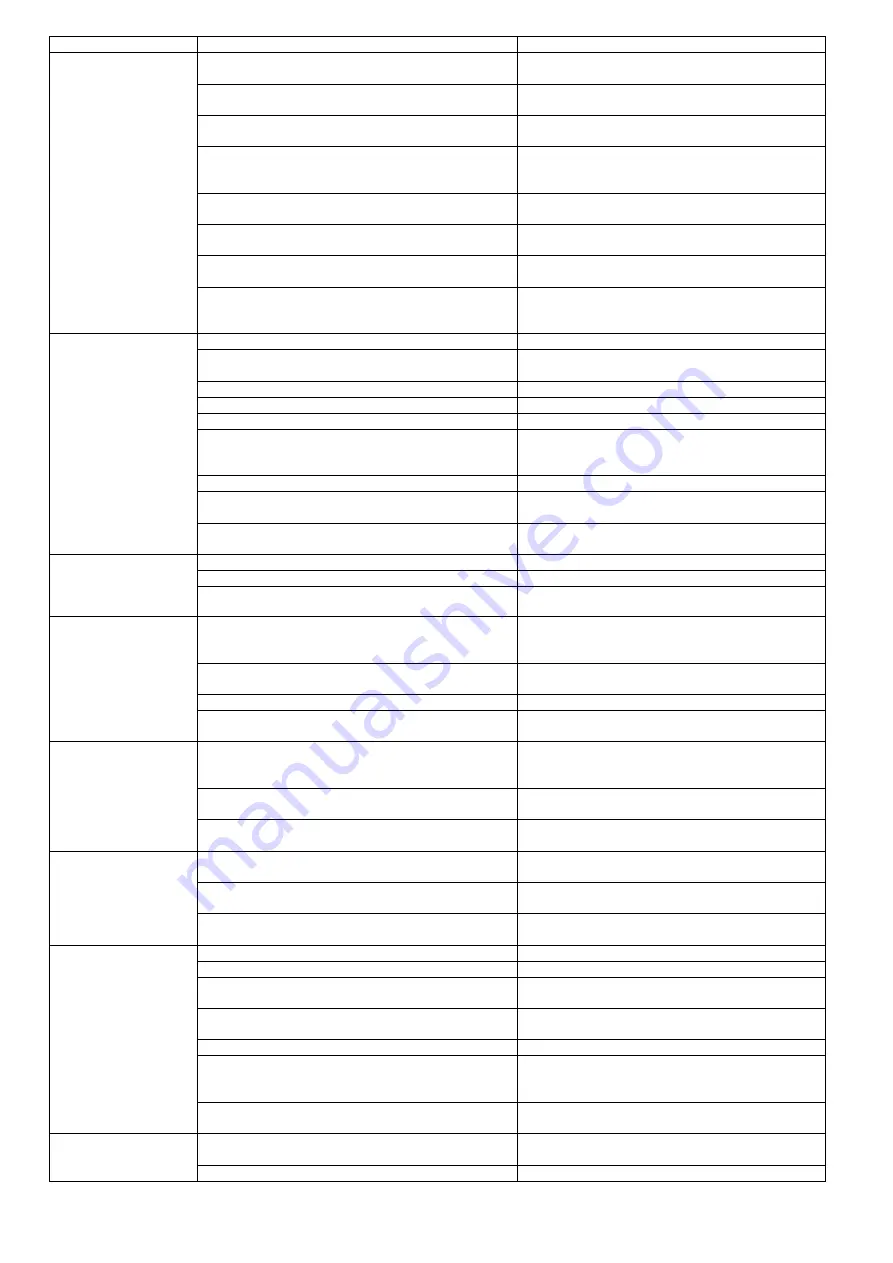

14

Problem

Reason

Solution

Effect of weather between the seasons.

See Chapter 11.5. “Operation between the

seasons”.

Primary air limiter (PAL) is dirty, blocking the

pendulum flap.

Clean primary air limiter (PAL)(see Chapter

12.3.).

Primary air limiter (PAL) is incorrectly installed,

blocking the pendulum flap.

Correctly install primary air limiter (PAL) (see

chapter 12.3.).

The seals on the burner (on fire chamber door,

electric ignition bar, cooking plate, pressure

equalisation plate) are defective.

Replace seals.

Pressure equalisation plate is not supported

properly.

Carefully place the pressure equalization plate.

With electric ignition the ignition bar on the burner

is not sealed or only insufficiently so.

Carefully seal the ignition bar.

Incorrect fuel is used for heating.

Use only Extra light fuel oil (ELFO) (see Chapter

11.1.).

Remove soot deposits with the help of a soot

removing agent (e.g. Wunderblitz soot removing

agent).

-

Stove cannot be

ignited,

-

No oil supply to

the burner

Oil tank or living room tank is empty.

Fill up oil tank or living room tank.

Defect in the central oil supply.

Look for cause of problem in the central oil

supply.

Controller latch on oil controller clogs oil supply.

Lift controller latch (see Chapter 11.3.).

Clogged oil filter.

Clean filter (see Chapter 12.2).

Oil inlet in burner insert clogged.

Operate cleaning crank (see Chapter 12.1.).

Water in the oil controller and/or in the oil line.

Completely empty oil controller and clean (see

Chapter 12.2.), disconnect oil lines between oil

controller and burner and drain.

Tank shut-off valve is closed.

Open valve.

Quick closing valve with central oil supply is

closed.

Open valve.

The liquid oil stove igniter does not work with new

stove.

Use wax strip or paraffin-saturated wick.

-

The oil stove heat

output is

insufficient

The output controller is set too low.

Set output controller higher.

The stove is not installed horizontally.

Align oil stove with water level.

The delivery pressure (chimney draught) is too low. Clarify with chimney-sweeper.

-

The oil stove heat

output is

excessive

The seals on the burner (on fire chamber door,

electric ignition bar, pressure equalisation plate)

are defective.

Replace seals.

Pressure equalisation plate is not supported

properly.

Carefully position pressure equalisation plate.

The output controller is set too high.

Set output controller lower

The delivery pressure (chimney draught) is too

high.

Clarify with chimney-sweeper.

-

View window

pane quickly

covered with soot

Imperative: every glass window must be cleaned

from time to time after use, see Chapter 12.4.

“Cleaning the appliance surfaces”.

The delivery pressure (chimney draught ) is too

low.

Clarify with chimney-sweeper.

Operate the oven for starting as described in

Chapter 12.4. “Igniting and normal operation” .

-

Stove has a

strong smell or

smokes on the

outside

Burning-in phase of the protective varnish or stove

is dirty/dusty.

Complete burning-in phase and clean the outside

of the stove when cold.

Oil lines leaking.

Seal loose screw connections by carefully

tightening the union nuts (without force).

When filling the tank oil was spilt or the tank was

overfilled.

See Chapter 12.2. “Filling the oil tank”.

-

Defect in the

electrical ignition

Ignition bar is defective.

Replace ignition bar (see Chapter 12.5.).

Microfuse is blown.

Renew microfuse (see Chapter 12.5.).

Electrical contact on the bimetal switch fails to

close.

Turn adjusting screw on the bimetal switch 1 to 2

turns in a clockwise direction (see Figure 17).

Defect on the fork toggle switch on the oil

controller.

Have the fork toggle switch replaced by technical

personnel.

Defect in the socket, supply cable or fuse.

Request electrician to check the fuses.

Ignition bar produces insufficient heat output

because of poor electrical contact on the ignition

bar.

Secure cable mounting screws on the ignition bar

(see Chapter 12.5.).

Ignition bar produces inadequate heat output

because ignition transformer is defective.

Have the ignition transformer replaced by

technical personnel.

-

Stove burns with

loud noise

Primary air limiter fails to work properly.

Maintain the primary air limiter (see Chapter

12.3).

Delivery pressure is too high.

Clarify with chimney-sweeper, see Chapter 11.