2. General information, safety instructions

Always observe the valid official regulations concerning

fire protection applicable in your country and the building

regulations applicable at the place of installation and

consult the responsible district master chimney-sweeper

when installing your stove. He will check the proper

connection of the appliance to the chimney. Obviously,

fuel oil will also have to be stored in accordance with the

regulations of the fire protection authorities and the

building authorities.

Your oil stove has been subjected to all tests required by

the legislator and it meets the specified requirements in

terms of design and operation, efficiency, safety

equipment and flue gas emissions.

Your stove described in these instructions has been tested

in accordance with DIN EN

1 (“heating stoves for liquid

fuels with evaporation burners and chimney connection”).

Oil stoves may be connected to a chimney with multiple

connections if such is permitted by the chimney dimension

(e.g. according to DIN 4705 Part 2).

Because of the necessary combustion supply air, windows

and doors in the installation room must not seal too tightly.

Adequate fresh air supply to the installation room of your

appliance must be ensured. The necessary minimum

amount of air must be able to flow to the oil stove

unobstructed even during the operation of exhaust

systems (bathroom exhaust fans, kitchen extractors etc.)

in your home or in any other connected rooms. Stove

operation is not jeopardized when the systems only

circulate the air within a room or the systems are equipped

with safety installations that automatically and reliably

prevent vacuum in the installation room. It is imperative

that you should clarify the adequate combustion air supply

with your master chimney-sweeper.

Please note that heat energy is liberated when burning

fuel materials which can heat the surfaces of the heating

appliance (doors, door and control handles, view window

panes, sidewalls, front wall, flue pipes). For this reason,

employ the necessary care when handling the appliance.

Do not wear any loose or easily combustible clothing when

heating up your stove!

Please note at all times: If the appliance has already been

heated the oil stove must only be restarted once the

burner insert has cooled down (hand warm) to avoid the

risk of a detonation with additional consequential

damages.

3. Data for calculating the chimney dimension

according to DIN 4705 Part

Models

Rate

d h

ea

t l

oa

d [

k

W

]

F

lue

ga

s

ma

s

s

fl

ow [g

/s

]

F

lue

ga

s

te

mp

erature at

rate

d h

ea

t l

oa

d [

°C]

Mi

ni

mu

m d

el

iv

ery

pres

s

ure at

rate

d h

ea

t

loa

d [

P

a]

Mi

ni

mu

m d

el

iv

ery

pres

s

ure at

0.8

ti

me

s

rate

d h

ea

t l

oa

d [

P

a]

F

lue

pi

pe

di

am

ete

r [m

m]

Ibiza 469.50

5,5 3,60 290

14

11

120

Viking 468.50 5,5 3,60 290

14

11

120

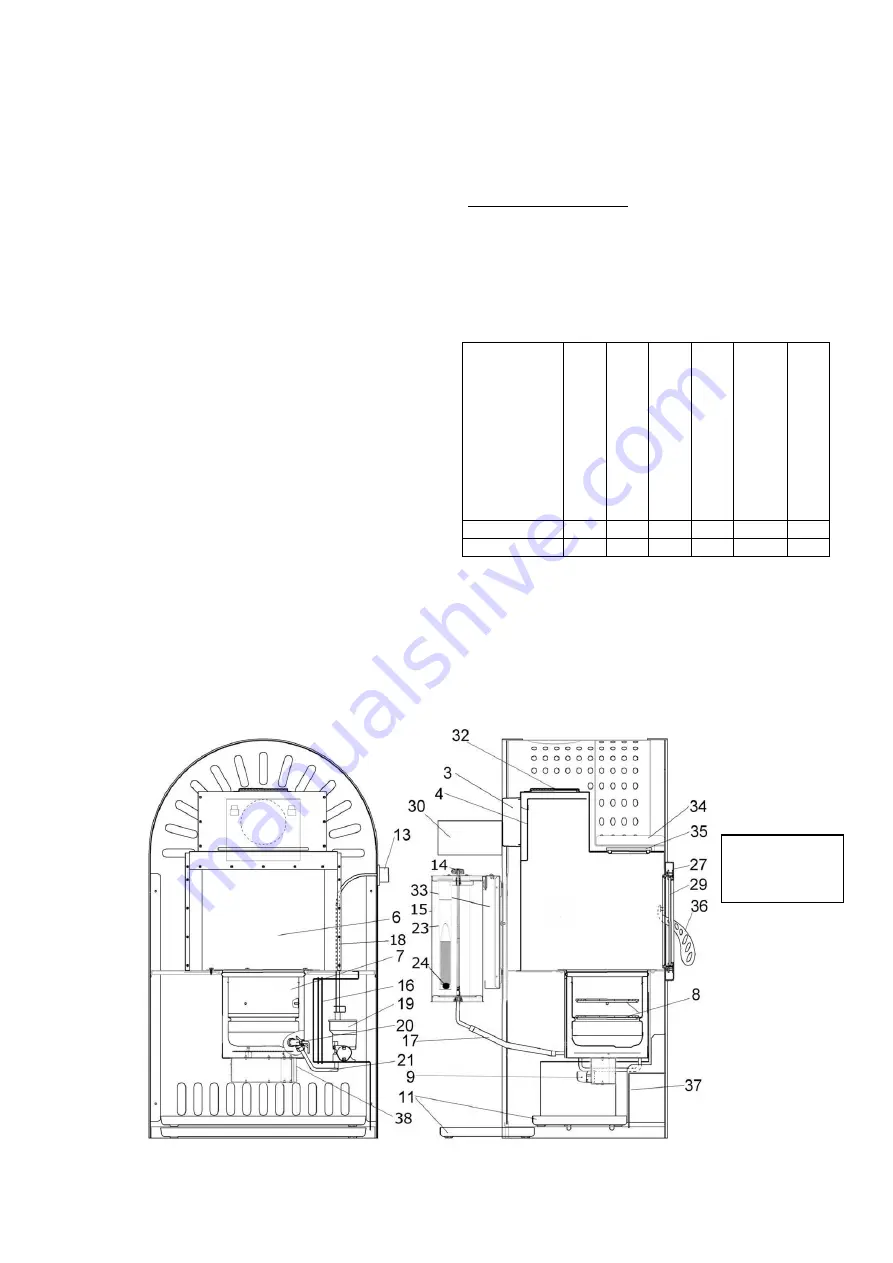

4.

Construction of the HAAS+SOHN oil stoves

Figure 1:

Oil stove

Viking 468.50