5.

Oil stove installation

Building authority regulations:

When installing the oil stove it is always imperative to

follow the fire protection regulations as directed by the

authorities (see Chapter 2 “General information, safety

instructions”). Ask your master chimney-sweeper in this

regard.

Safety distances (Minimum distances):

A minimum distance of the heating appliance from

combustible or temperature-sensitive materials (e.g.

furniture, wallpaper, wood panelling) or from supporting

walls made of reinforced concrete of

20 cm

to all sides

must be maintained.

Installation surface:

On

combustible

or

temperature-sensitive

floor

coverings the appliance must be placed on a non-

combustible protective floor plate (e.g. steel plate,

glass). Protective floor plates (support plates) are

available in our accessories program. These can be

ordered from your specialist stove dealer if required.

Appliance installation:

Horizontally align the oil stove on the installation

surface in longitudinal and transverse directions using

a water level. Possible irregularities on the installation

surface must be evened out!

IMPORTANT:

If the oil stove is placed on uneven

ground the oil flow is inaccurate and operating

malfunctions can occur.

Appliance packaging:

The packaging of your new oil stove optimally protects

it from damage. However, damages to stove or

accessories may have occurred during transport

regardless. For this reason examine your oil stove for

damages

and

completeness

after

unpacking!

Immediately report defects to your specialist stove

dealer!

The

packaging

of

your

oil

stove is

largely

environmentally neutral. The cardboard, wooden parts

and the plastic materials can be disposed of to the

communal waste disposal without problems.

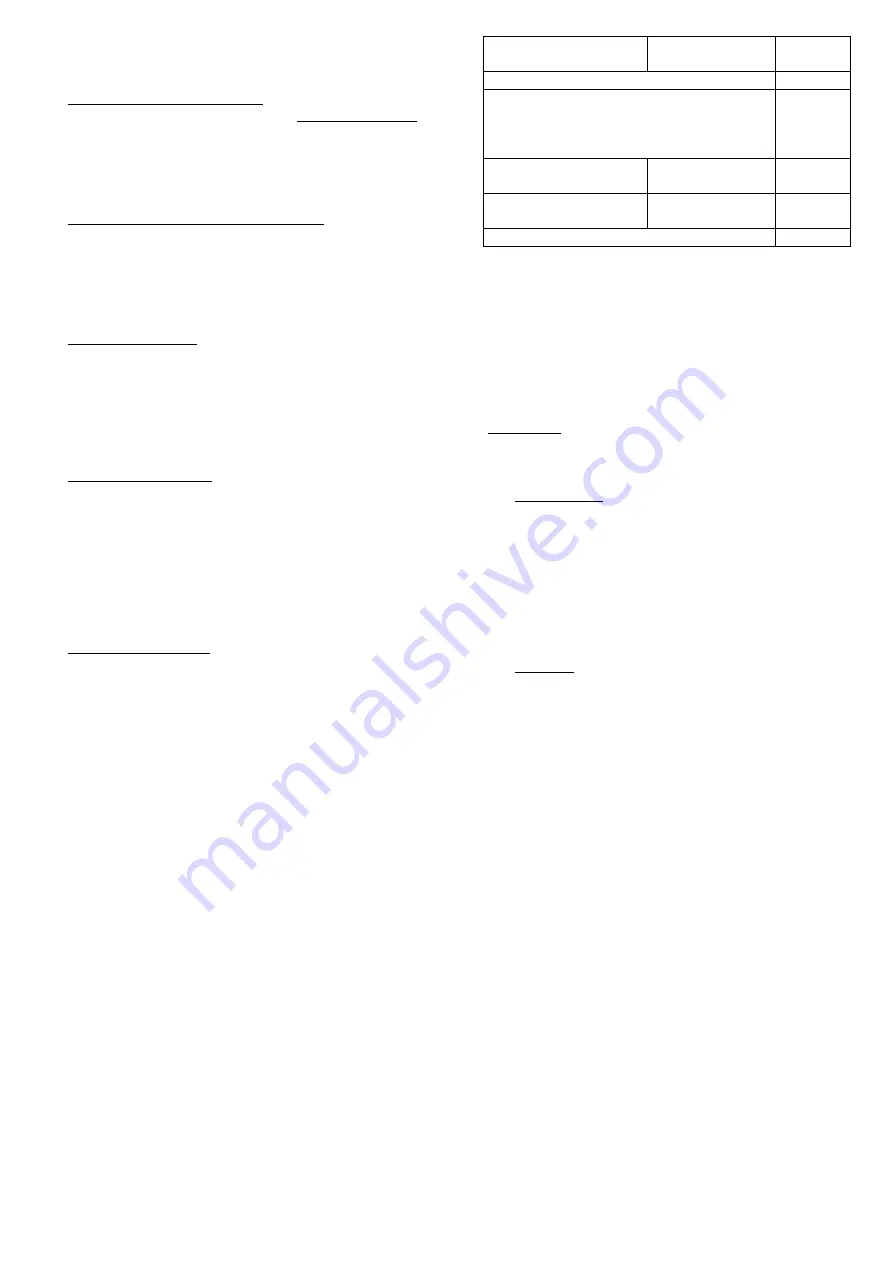

6. Connecting the appliance to a central oil supply

(COS) or to a living room tank

You will require at least the following accessories for

connecting your oil stove:

Connection to central

oil supply

Connection to

living room tank

Article

No.

1 straight ferrule screw connection 8x8

102151

1 flexible fuel oil hose:

50cm

75 cm

100 cm

104212

104213

104214

1 pressure controller

8x8

-

105170

1 oil pump

-

z.

B.100280

1 quick-closing valve

105146

Additional

accessories

(angular

ferrule

screw

connections, T-ferrule screw connections, reducing

screw connections, oil flow meter, filter, change-over

valves etc.) are always available from your specialist

dealer.

For subsequent conversion it is first necessary to drain

the oil tank or use up the tank content through heating

and to drain the oil in the oil controller.

Procedure:

1. To connect the oil stove to a central oil supply

(COS) or to a living room tank, unscrew the oil

connection line between oil tank and oil controller

from the tank.

2. Cut the line at a suitable point (e.g. in the middle,

with flexible oil lines at the end) (the screw

connection piece is not longer required) and

carefully bend the line so that the free end faces to

the back.

3. Fit the straight ferrule screw connection 8x8.

4. Connect another flexible fuel oil hose (see above

table) on the other side of the screw connection.

5. Next install the pressure controller which is

essential for connection to a COS. If the living

room tank is not installed on the same floor as the

oil stove, you will also require a pressure controller.

The working pressure on the oil controller must

not

exceed 30 kPa (300 mbar)!

6. Attach the quick closing valve.

7. You can now connect this valve to the line of the

COS or the living room tank

– you might need

reducing screw connections.

8. Finally check all oil lines and screw connections for

leaks. Seal loose screw connections by tightening

the union nuts. Do not tighten these connections

excessively (do not use force), otherwise the

connection threads could be damaged.

7. Installation and configuration of the oil tank and

inserting the oil pan

Your oil tank is equipped with an oil collection pan as

required. However the Haas+Sohn oil stove models

“Ibiza” and “Viking” can be optionally retrofitted with an

oil tank. To this end, an oil pan or an oil guide plate

must be additionally installed (see figures 1+ 2).

Pre-assembling the tank: