10

96-0012 rev G

June 2003

O

M

PERATOR’S

ANUAL

A u t o m a t i c

A u t o m a t i c

A u t o m a t i c

A u t o m a t i c

P a l l e t C h a n g e r

P a l l e t C h a n g e r

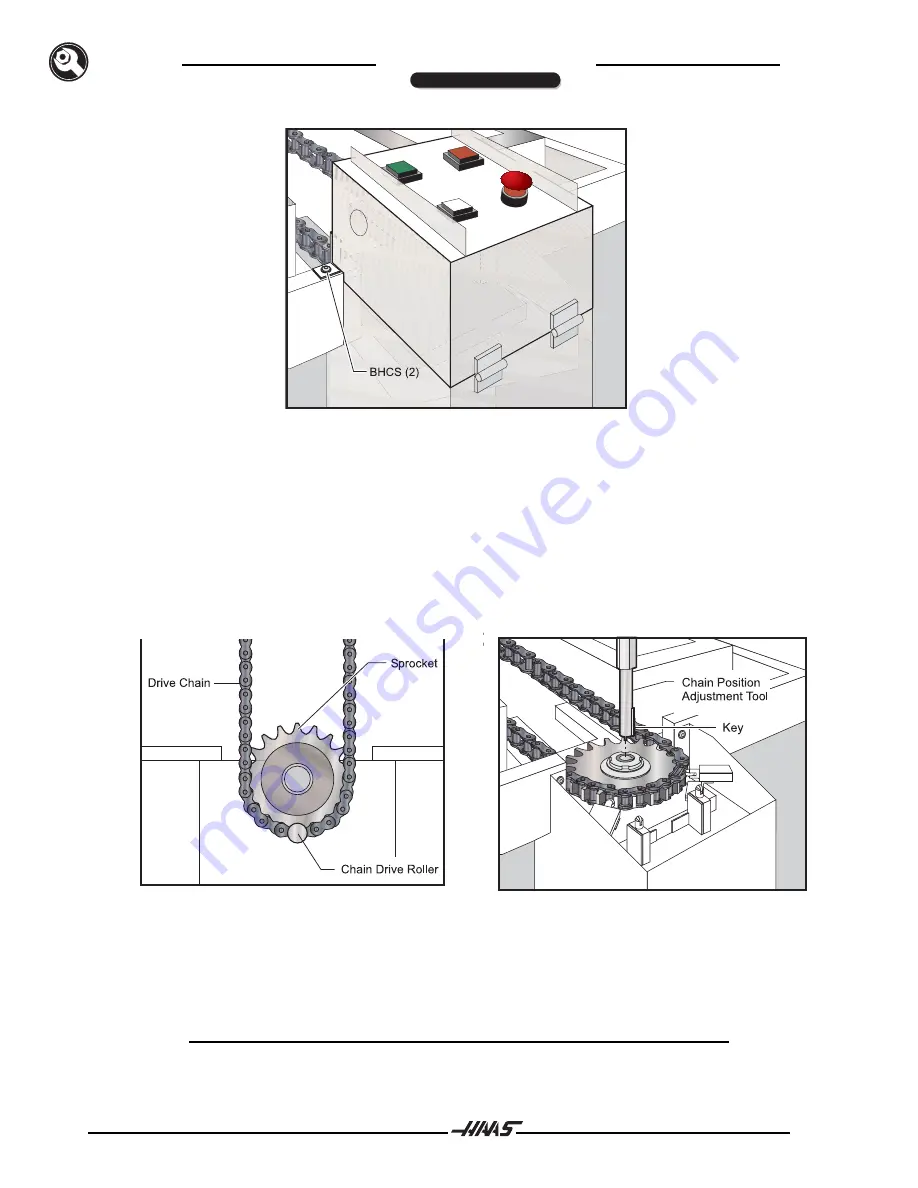

Figure 3.8 APC operator's panel cover.

17.

Ensure that the drive roller on the APC chain is centered under the control box, as shown in Figure

3.9. If not, use the chain position adjustment tool to rotate it into this position.

To use this tool, place it into the center of the drive sprocket with the key in the sprocket's keyway (see Figure

3.10). Note that the tool only goes about 1/4" into the sprocket. Push down and turn the tool with a wrench in

order to position the chain.

Important! Remember to remove the adjustment tool when finished.

Figure 3.9 Chain drive roller positioning.

Figure 3.10 Chain position adjustment tool placement.

18.

Insert two 1/2"-13 eyebolts into each pallet (see Figure 3.11). Attach straps or chains to the

eyebolts, and use a forklift or hoist to lift each of the pallets onto the APC. Ensure that each pallet

is placed with it's drive leg pawl under the APC operator's panel, and that the APC rollers fit into

the grooves on the bottom of the pallets (see Figure 3.12).

NOTE:

Be careful not to set the pallets on top of the chain drive roller. If necessary,

rotate the chain slightly using the chain position adjustment tool.

INSTALLATION