ES0755 rev A 1/11

13

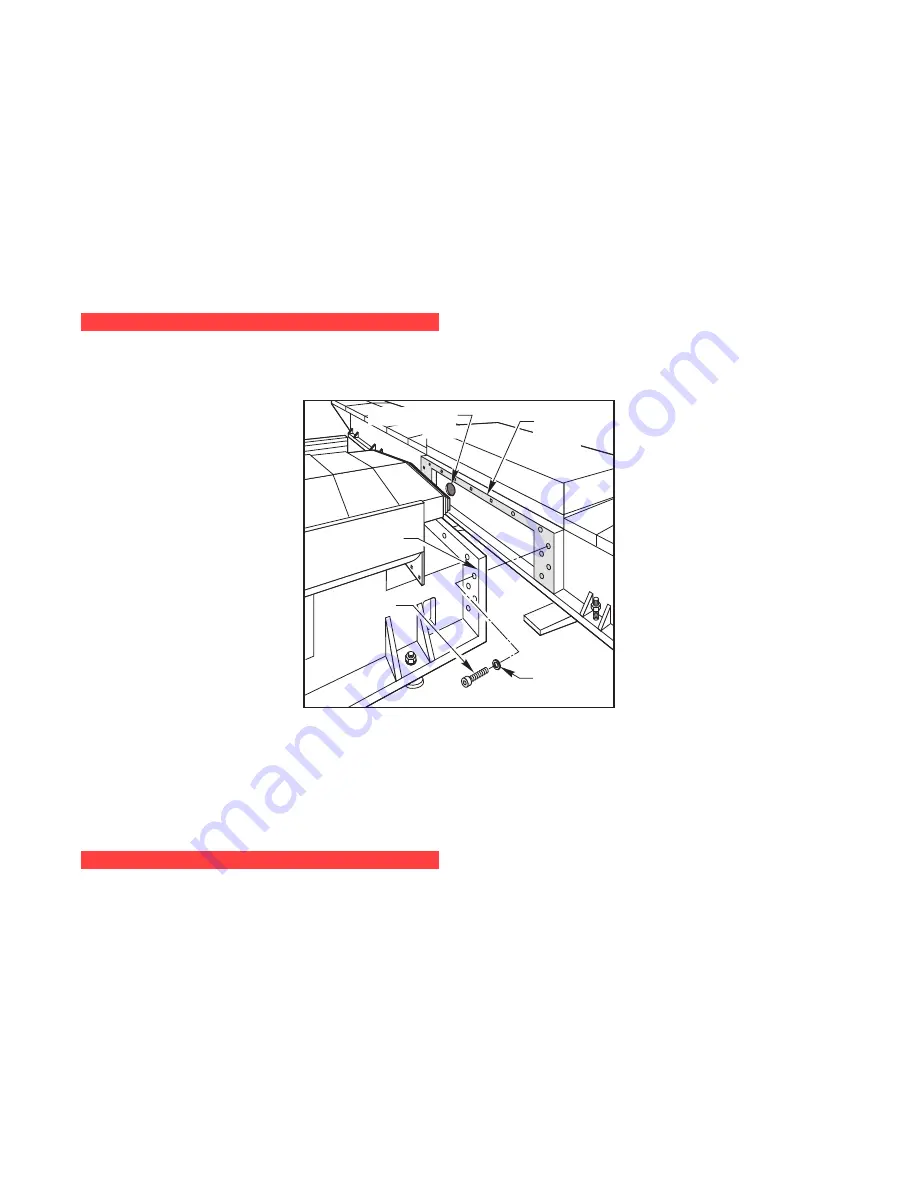

2. Remove the two shipping blocks and hardware completely from the column base.

3. Raise the spindle head to the full up position and support the bellows.

4. While ensuring the lower bellows do not fall, handle jog (without zero return) the Z-axis (HS) /

Y-axis (VS) toward the rear of the machine until access to the bolts holding the forward shipping

blocks are accessible.

5. Remove the front shipping blocks completely from the column base.

6. Check that the Y-axis (HS) / Z-axis (VS) cables are properly routed and the cable guide is secure

-

ly attached to the base.

7. Zero return the Y-axis (HS) / Z-axis (VS).

m

achine

l

evelinG

and

G

eometry

c

heck

At this point the machine is completely unblocked and all axes are enabled. The process of leveling can now

begin.

Lockwasher

(19)

SHCS (19)

Column Base

Mating Flange

Cable Access

Hole

Table Base

Mating

Flange

The following criteria should have already been met at this point

• The machine correctly placed with respect to the anchoring points.

• The very rough leveling has taken place, ensuring that the bottom of the two bases are very close to

2 inches off the floor.

• The mating flanges of the two bases have been pulled into contact.

• The screws that connect the two bases have been backed off and can rotate freely.

o

verview

of

l

evelinG

the

m

achine

When leveling the machine the best results are achieved when the entire machine is leveled with respect to

the earth. For the table that means that over the entire travel of the X-axis the table is level to earth in the

direction across the table as well as along the length of the table. For the column base the same concept ap-

plies, but a slight modification may occur when checking the perpendicularity of the Z-axis to the X-Y plane of

the machine.

Leveling and squaring the machine is an iterative process where a change of level in one part of the machine

can and will affect the geometry in another part of the machine. The process is begun by establishing a known

level datum plane that is the table surface in the center of travel, and all subsequent geometry is with respect

to that plane.

The general profile of the process of leveling and squaring the machine is as follows: