ES0755 rev A 1/11

23

position press

<A>

to go to the control screen for the tool changer’s arm functions. The next screen states:

Hydraulic tool changer bump arm

Using arrow keys attempt to move the arm into its home position

Pressing the cursor keys will move the tool changer’s arm and carriage.

NOTE

: The tool changer arm and carriage assembly will ‘jerk’ and ‘shake’

when it is operated manually by using the control panel keys.

Because the motion is somewhat erratic, the safety of personnel

and equipment should be taken into consideration when operating

in this mode.

WARNING!

When operated in the manual mode it is possible to move the tool changer arm and carriage into a

position that may damage the tool changer and/or the horizontal mill. Before manually operating the

tool changer the machine operator must fully understand the motion of the tool changer’s arm and

carriage during a normal tool change cycle.

Most importantly do not attempt to swing the tool changer arm towards the spindle unless the

phrase “Arm Home” is displayed on the T/C recover screen.

4. The next step in the alignment procedure is to move the tool changer arm to its

HOME

position by using

the cursor buttons. The following buttons are used to manually jog the tool changer:

Home Button

Swing arm towards spindle

Page Down

Swing arm towards magazine

Up Arrow

Pull arm in

Down Arrow

Push arm in

End Button

Rotate arm counterclockwise

Page Up

Rotate arm clockwise

Left arrow

Slide arm to left

Right arrow

Slide arm to right

The

HOME

position is defined as

:

a. The arm is

fully rotated

toward the magazine, using the

<PAGE DOWN >

button.

b. The arm is

fully pulled in

, using the

<^>

up arrow button.

c. The arm is rotated

fully clockwise

or

fully counterclockwise

, using the

<END>

button or the

<PAGE

UP>

button until the arm is in a horizontal position.

d. The arm is moved

fully to the right

, using the

<>>

right arrow button.

When the tool changer arm has been moved into its

HOME

position the control panel screen will display a

highlighted line that states

ARM HOME

. Prior to reaching the

HOME

position the display screen will be blank

in this area. As a check, when the arm is in the

HOME

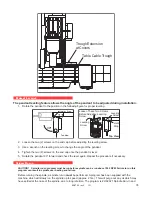

position, the cam follower on the bottom of the slide

mechanism will be in-line with the cam slot on the guide plate.

By using the cursor keys and the messages displayed on the

TOOL RECOVERY

screen, move the tool

changer’s arm into its

HOME

position. The tool changer arm and carriage must be moved to their

full limit

of

travel to achieve the

HOME

position. Even when it appears that the full limit of travel has been reached, push

the button several more times to ensure that, in fact, the full limit of travel has been reached.

5. Zero return all axis. Press

MDI

then

ORIENT SPINDLE

.

6. Press

TOOL CHANGER RESTORE

. Follow the displayed instructions until

TC RECOVER

screen appears.

7. Press

HOME

until the tool changer swings in and into hydraulic lock, this can be achieved by bumping the

key several times after the tool changer comes to a stop.

8. Press

>

until the tool changer double arm slides all the way in and into hydraulic lock. Place a magnetic

level on the face of double arm, plumb and level the tool changer by adjusting leveling screws at the base of

tool changer. Insure that the key tab on double arm aligns with the dog on the spindle.