ES0755 rev A 1/11

24

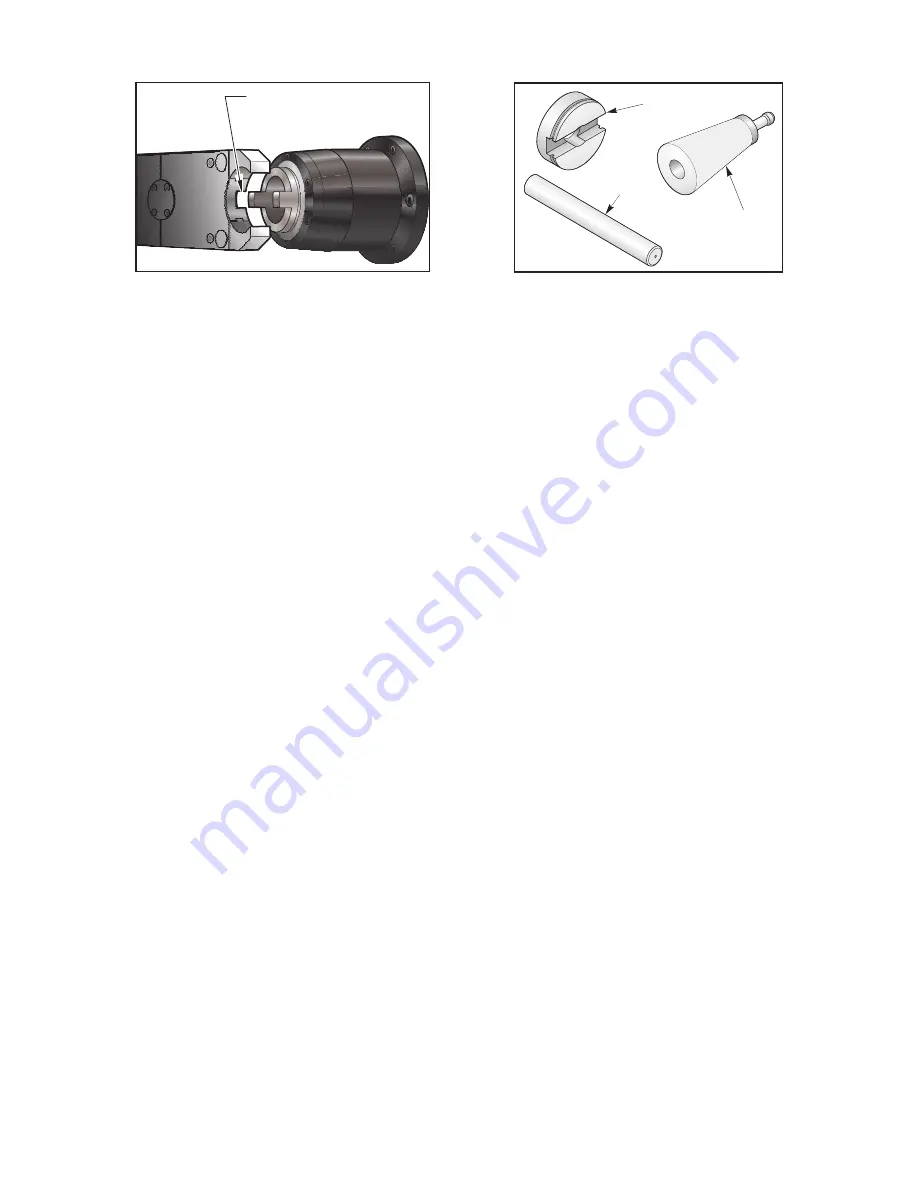

Key Tab

Jig

Dowel Pin

Taper

Key Tab Alignment

Alignment Jig

9. Press

PAGE DOWN

until the tool changer is back to the stow position. Using the alignment jig dowel pin,

push the top half of the jig into the double arm fingers. Insure that it is inserted properly and that the flat side

faces the spindle. Press

TOOL RELEASE

and install the taper into the spindle.

10. Press

HOME

and swing the tool changer towards the spindle. Insure it is in hydraulic lock.

11. Press

>

and slide the double arm all the way to the spindle until it locks. Adjust the three transition (slide)

bolts until the jig halves are aligned by sight. Insert the dowel pin, if it goes all the way through, the alignment

is complete. Tighten the lock nuts on the slide and leveling bolts. If the dowel pin does not go through all the

way, continue with fine adjustments using the slide and leveling bolts to adjust the tool changer left, right and

perpendicular to the spindle.

12. Press

ALARM MESGS

, type “DEBUG” and press

ENTER

. Press

POSIT

, Press

HANDLE JOG

and

jog the Z axis until the air gap between the jig halves is 1.5mm (.059”) in all directions. Enter the value into

parameter number 64 (omit the decimal point).

13. Handle jog the Y-axis moving the spindle up or down to align jig halves. Enter the value into parameter

number 211 (omit the decimal point).

14. Rotate the arm and switch the alignment jig to the other side. Adjust as necessary so that the alignment

pin inserts fully. Repeat steps 11-13 until the dowel pin inserts fully in both sides of the arm.

15. Tighten all locking nuts. Home tool changer and magazine. Exit from tool changer restore mode by

pressing jog handle mode.

Setting the Tool Change Position Parameters

Without moving the tool changer arm, spindle or column from the position achieved in Step 15:

1. Go to the

SETTINGS/GRAPH

display screen by pressing the <

SETNG/GRAPH

> button.

2. Go to Setting

#7

,

PARAMETER LOCK

and change it to

OFF

by pressing <

>

> (right arrow) button and then

press the <

WRITE/ENTER

> button to save it in memory.

3. Go to the

ALARMS

display screen by pressing the <

ALARM/MESGS

> button. Type in

DEBUG

from the

keypad and press the <

WRITE/ENTER>

button.

4. Move to the

POSITION

display screen by pressing the <

POSIT

> button. Press the <

PAGE UP

> button to

move to the

POS-RAW DAT

screen.

5. Record the values shown in the

ACTUAL

column for the position of the Y and Z-axes.

6. Go back to the

ALARMS

screen, type in

DEBUG

and press the <

WRITE/ENTER>

button to exit the

DEBUG

mode.

7. Press the <

E-STOP

> button to allow parameters to be changed.

8. Go to the

PARAMETERS

display screen by pressing the <

PARAM/DGNOS

> button. Go to Parameter

#211, Y Tool Change Offset,

on the

“Y PARAM B”

screen. Enter the number (with the correct sign) recorded

from the

POS-RAW DAT

screen for the Y-axis and press the

WRITE/ENTER

button.