ES0755 rev A 1/11

29

c

oolant

s

ystem

i

nstallation

c

oolant

s

eParator

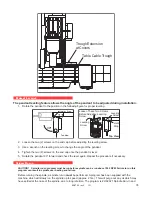

The coolant separator is mounted in its shipping position. Remove the two screws and remount the coolant

separator in the lower mounting location. Do this for

both of the coolant separators.

Cable

Trough

Coolant Separator

Operating Position

Coolant Pump,

coolant level sensor

and TSC cables

Coolant Trough

Route the coolant tank and TSC (optional) cables through the coolant trough. If necessary remove the trough

(2 screws) to ensure that the cables are properly routed.

c

oolant

t

ank

I

nstallation

1. Position the coolant tank.

Electrical Sub-Panel

NOTE:

It is important that the coolant tank is in place before leveling the

machine to ensure there is adequate clearance (height) between

the bottom of the auger trough and the tank.

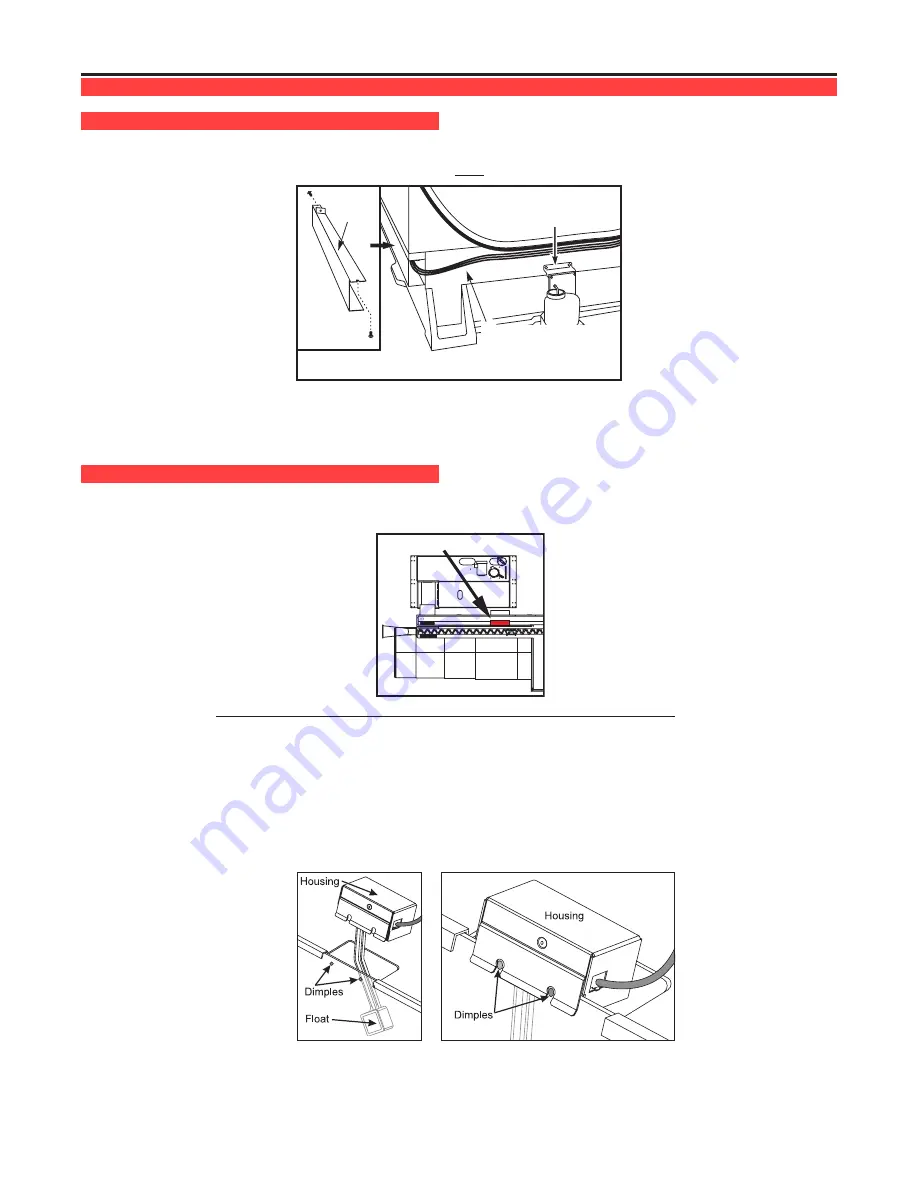

2. The Coolant Level Float Assembly is shipped in a separate box. It consists of a housing, float and cable.

Install the Coolant Level Float Assembly by lowering the float through the tank lid. Line up the slots in the

housing with the dimples on the side of the tank and press down so the float assembly clips onto the tank.

95-Gallon coolant tank

- The float can be mounted on either the edge of the coolant tank or the center.

3. Insert a plastic push wire mount into the hole in the tank lid, then route the cable to the coolant pump(s). Tie

wrap the coolant float cable to other cables, when available, when routing from the coolant tank (see figure).