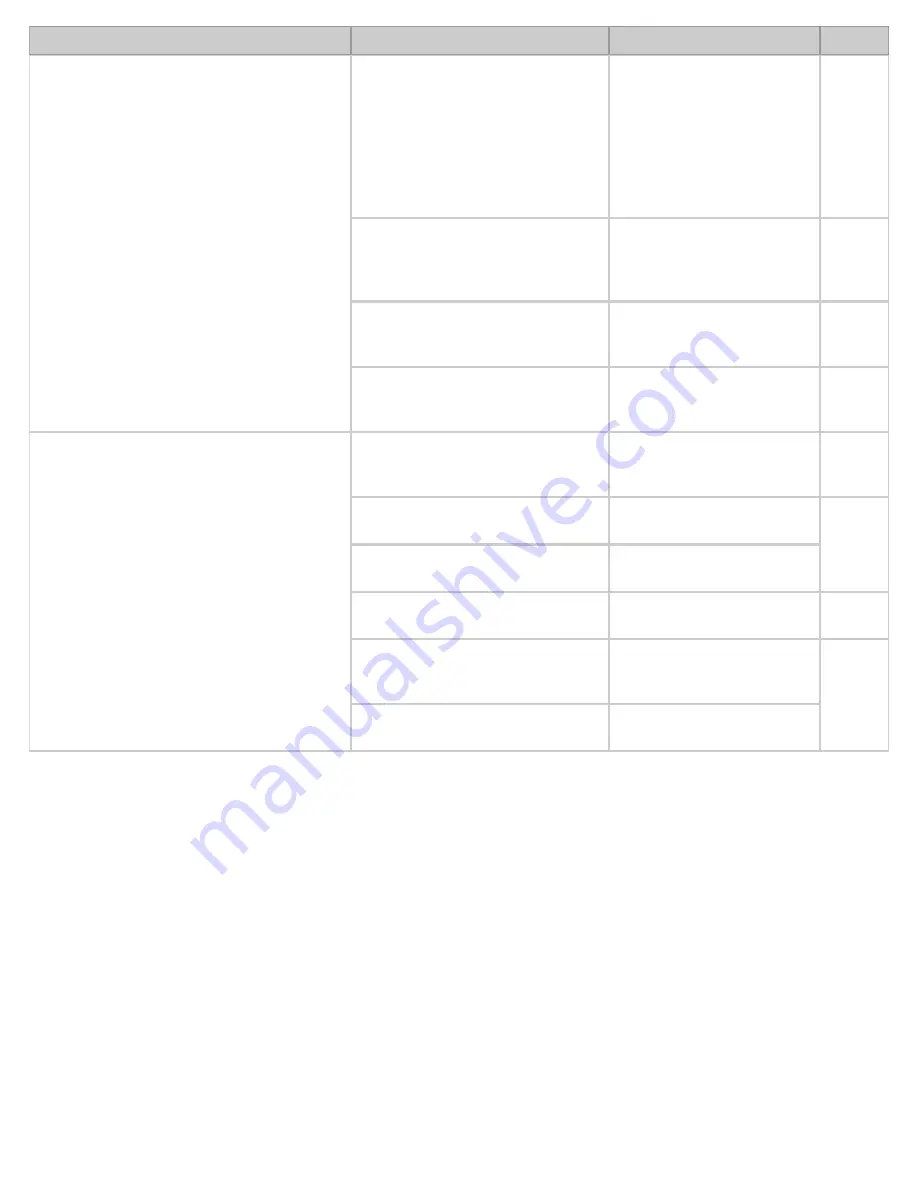

Symptom

Possible Cause(s)

Corrective Action(s)

Section

Alarm

151

LOW THROUGH SPINDLE

COOLANT

A short circuit in the pump motor or

pump motor cable caused a fuse to

blow or a circuit breaker to trip.

Check the circuit breakers

and fuses on the power

supply PCB.

Check for shorts in the TSC

pump cable and the motor

leads.

1

Incorrect power phasing - the

pump motor is running backward.

Check the phasing

indicators and change the

incoming power cables, if

necessary.

2

Damage to the motor shaft key,

shaft collar, or wear in other parts

of the pump head assembly.

Inspect the motor shaft /

pump head assembly.

3

The TSC pressure sensor is

defective. Some coolant flow may

occur if this is the case.

Troubleshoot the coolant

pressure sensor.

4

Low coolant flow, no alarm.

Low coolant flow, the pump cavitates

(cavitation sounds like heavy grit in the

pump head, or a suction sound) or is

otherwise noisy

Damage to the motor shaft key,

shaft collar, or wear in other parts

of the pump head assembly.

Inspect the motor shaft /

pump head assembly.

3

The coolant does not return to the

coolant tank fast enough.

Remove chip buildup from

the coolant return path.

5

The coolant level in the coolant

tank is low.

Fill the coolant tank.

The pressure relief spring in the

pump head is damaged.

Inspect the pressure relief

spring.

6

The TSC pump filter or intake

strainer is clogged.

Clean the filters. Remove

chips from the coolant

system.

7

The Auto-clean coolant pump filter

does not work (if equipped).

Test and troubleshoot the

Auto-clean pump filter.

Copyright 2020 by Haas Automation, Inc. No unauthorized reproduction | Last Published On December 26, 2016

3/8