Section 3

Symptom:

Alarm

151

LOW THROUGH SPINDLE COOLANT.

Low coolant flow, no alarm. Low coolant flow, the pump

cavitates (cavitation sounds like heavy grit in the pump head, or

a suction sound) or is otherwise noisy.

Possible Cause:

Damage to the motor shaft key, shaft collar, or

wear in other parts of the pump head assembly.

Cutting abrasive materials causes premature wear on the

coolant system, resulting in reduced pressure. Use additional

filtration when you cut abrasive materials.

Corrective Action:

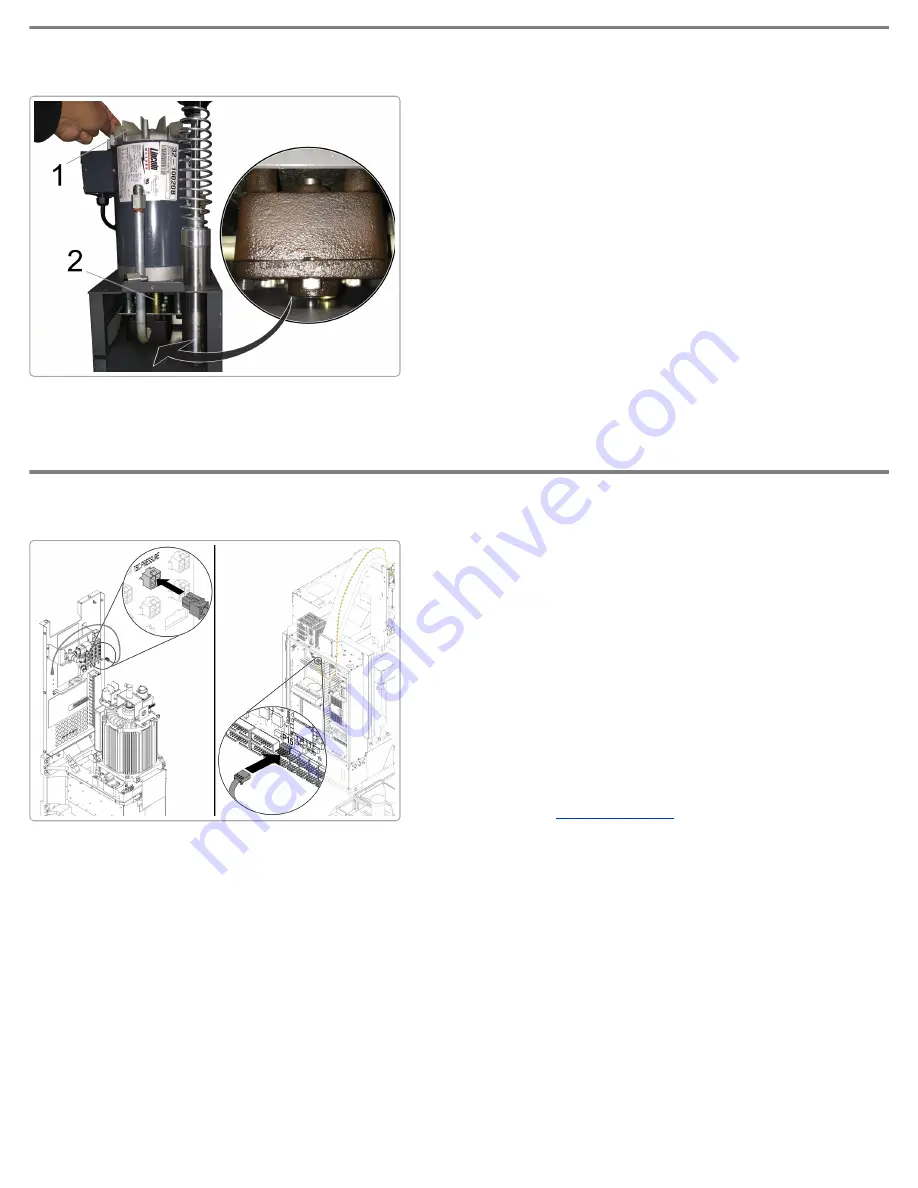

Remove the pump from the tank. Rotate the pump motor fan [1]

by hand clockwise. Make sure that the pump coupling [2] also

turns.

If it does not turn, separate the pump from the motor. Check for a damaged key on the motor shaft.

Section 4

Symptom:

Alarm

151

LOW THROUGH SPINDLE COOLANT.

Possible Cause:

The TSC pressure sensor does not work.

Some coolant flow may occur if this is the case.

Corrective Action:

Press

[PARAM/DGNOS]

. Go to the I/O diagnostics page.

Short the sensor connector leads. The

Low TSC Pressure

bit

state should change from 1 to 0.

If it does not change, then the cable or the I/O PCB is damaged.

Measure for resistance at both ends of the cable. If the cable has

resistance, go to

The pressure switch is connected to a bracket above the spindle. Replace the pressure switch if it is defective:

If the bit changes, use an inline pressure gauge to verify the pressure is correct. If the pressure is over 40 psi, replace the

switch.

Copyright 2020 by Haas Automation, Inc. No unauthorized reproduction | Last Published On December 26, 2016

6/8