1-15-96

96-8100

171

TABLE OF CONTENTS

TECHNICAL REFERENCE

S E R V I C E M A N U A L

VF-S

ERIES

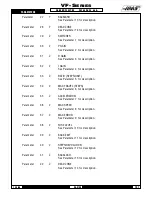

16. SWITCHES

16.1 LAMP ON/OFF SWITCH

An on/off switch is supplied for the operators lamp. It is located on the side of the control cabinet below all of the motor

connectors.

16.2 DOOR OPEN SENSE SWITCH

The DOOR OPEN sense switch is a magnetic reed switch type and consists of two switches; one on each half of the enclosure

front doors. These switches are normally closed and wired in series. When the doors open, one or both of these switches

will open and the machine will stop with a Door Hold function. When the door is closed again, operation will continue

normally.

The wiring for the door switches is wired in either of two paths. The first one applies to machines built before

March 1990; this uses connector P5 at the side of the cabinet and routes the wires past the oiler and through the base of the

mill. The second wiring routes through the front panel support arm and down through the top of the plastic enclosure.

If the doors are open, you will not be able to start a program. Door hold will not stop a tool change operation, will not turn

off the spindle, and will not turn off the coolant pump.

The door hold function can be temporarily disabled with Setting 51, but this setting will return to OFF when the control is

turned off.

16.3 LIMIT SWITCHES

NOTE:

There are fourteen (14) limit switches located on the VMC, and some are difficult

to reach. Ensure the problem is the switch before beginning removal procedures. The

following is a list of all switches, their general location, and a functional description:

CLAMP/UNCLAMP SWITCHES

[Tool Release Piston Assembly (2)]

There are two switches used to sense the position of the tool clamping mechanism. They are both normally closed and one

will activate at the end of travel during unclamping and the other during clamping. When both switches are closed, it

indicates that the draw bar is between positions.

A tool change operation will wait until the unclamped switch is sensed before the Z-axis pulls up from the tool. This prevents

any possibility of breaking the tool changer or its support mounts.

The diagnostic display can be used to display the status of the relay outputs and the switch inputs.

SPINDLE ORIENT SWITCH

[Top rear of transmission]

A normally-open switch that is held closed is used to sense when the pin drops in to lock the spindle. When the pin drops

the switch opens, indicating orientation is complete.

The normally-closed side of the same switch that is held open, is wired to the spindle drive and commands it into a Coast

Stop condition. This is done to ensure the spindle motor is not powered when the pin is locking the spindle.

Summary of Contents for VF-SERIES

Page 180: ...1 15 96 96 8100 177 TABLEOFCONTENTS TECHNICAL REFERENCE SERVICE M A N U A L VF SERIES ...

Page 235: ...96 8100 1 15 96 232 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 COLUMN ...

Page 237: ...96 8100 1 15 96 234 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 LEADSCREW ...

Page 239: ...96 8100 1 15 96 236 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 COLUMN ...

Page 241: ...96 8100 1 15 96 238 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 LEADSCREW ...

Page 245: ...96 8100 1 15 96 242 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS 3 4 2 1 ...