37

Rossi

HB-1.0001 РЭ

torque Mfmax (see Tab. 5) with a tolerance of ± 18%.

Table 5 Periodic maintenance

For a correct application it is necessary to adjust the braking torque according to specifi cations of

the driven unit.

For general applications it is normally advisable to set braking torque at about two times the nominal

braking torque of the motor.

Anyway, the braking torque value must be specifi ed on the nameplate. If the braking torque is set

at a value less than the minimum stated on nameplate, it is possible to have inconstant brakings

strongly aff ected by temperature, duty cycle and wear conditions. If there is a value set higher than

the maximum one stated on the nameplate, it is possible to have missing or partial brake release

with consequent vibrations and overheatings of electromagnet and also of motor and mechanical

stresses aff ecting brake and motor life.

Braking torque is directly proportional to preload of braking springs 17 and can be changed by

modifying the self-locking nuts 44 making sure to preload uniformly all springs (see. fi g.3).

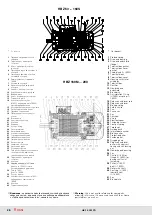

Figure 3 Brake

For the adjustment follow Table 5 stating the values of springs length according to the braking

torque percentage (Mf %) compared to maximum value Mfmax.

Important: values thus obtained can slightly diff er from value desired. Therefore, it is advisable to

verify eff ective braking torques achieved through

a dynamometric key inserted on the drive end motor shaft. Before commissioning, close the motor

with the brake cover.

Insulation resistance control

Before putting into service and after long stillstanding or storing periods it is necessary to

measure insulation resistance between the windings and to earth by adequate d.c. instrument

(500 V).

Attention! Do not touch the terminals during and just after the measurement because of live

terminals.

Insulation resistance, measured on winding at +25°C, must not be lower than 10 MΩ for new

winding, lower than 1 MΩ (GOST R IEC 60204-1-2007) for winding run for a long time.

Lower values usually mean the presence of humidity in the windings; in this case let them dry

(with warm air fl ow or by applying the AC voltage not exceeding 10% of the rated voltage to the

windings connected in series).

For use under long overloads or jamming conditions, cut-outs, motor protections, electronic

torque limiters or other similar devices should be provided.

Where duty cycles involve a high number of on-load, it is advisable to utilize thermal probes for

motor protection (fi tted on the wiring);

magnetothermic breaker is unsuitable since its threshold must be set higher than the motor

Размер тормоза

Brake size

Размер двигателя

Motor size

g

Люфт

Air-Gap

S

min

M

f

[N m]

таблички

of name plate

L

пружины для

%

M

fmax

[mm]

L of spring for % M

fmax

[mm]

35,5

50

71

100

mm

mm

mm

min

max

3)

nom. max

2)

BF 12

63, 71

0,5

0,25

0,40

6

–

–

–

–

–

–

BF 53, 13

71, 80

0,5

0,25

0,40

6

–

–

–

–

–

–

BF 04, 14

80, 90

0,6

0,30

0,45

6

–

–

–

–

–

–

BF 05, 15

90, 100, 112 0,6

0,30

0,45

8

–

–

–

–

–

–

BF 06S

112

0,7

0,35

0,55

7

–

–

–

–

–

–

BF 06

132

0,7

0,35

0,55

7

–

–

–

–

–

–

BF 07

132, 160S

0,7

0,40

0,60

7,5

–

–

–

–

–

–

FA 09

160

–

0,50

1

12

40

200

25,4

24,6

23,5

22

FA G9

180M

–

0,65

1,15

6

60

300

22,2

21

19,3

17

FA 10

180M, 200

–

0,65

1,15

6

80

400

37,8

36,5

35,2

33,5

Summary of Contents for Rossi HB

Page 2: ...2 Rossi HB 1 0001...

Page 6: ...6 Rossi HB 1 0001 1 3 15 40 C 20 C 50 C 1 000 52776 2007 60034 1 2004 1 4 1 5 1 6 1 7...

Page 7: ...7 Rossi HB 1 0001 1 8 1 2 20 C 50 C 10 70 1 9...

Page 8: ...8 Rossi HB 1 0001 2 2 1 2 2 20 5 C 60 2 ATEX 94 9 EG II 1 6 2...

Page 9: ...9 Rossi HB 1 0001 2 3 1 2 3 4 5 Rossi 1 Ve 3 5 PN 15 Ve 4 5 PN 15 Ra 6 3 m...

Page 12: ...12 Rossi HB 1 0001 3 5 Mf Mfmax 500 25 C 10 M 1 M 60204 1 2007 10 4...

Page 14: ...14 Rossi HB 1 0001 HBZ HBV HBVM RN1 RR1 RR8 30804 6 1 2013 160S 160M HBZ HBV HBVM 6...

Page 16: ...16 Rossi HB 1 0001 7 HBZ HBV HBVM 6 HBZ SB SU 7 HBF 160S Y Y 160M Y 8...

Page 18: ...18 Rossi HB 1 0001 2 4 1 2 3 4 1 2 1 2 3 4 5 6 7 2 5...

Page 19: ...19 Rossi HB 1 0001 3...

Page 20: ...20 Rossi HB 1 0001 1 4 Rossi 2 Y tcarc tamb 70 C 1 Rossi Y Rossi 1 Rossi...

Page 21: ...21 Rossi HB 1 0001 Y Rossi Rossi HBF 160M Rossi...

Page 22: ...22 Rossi HB 1 0001 4 WEEE 5 5 12...

Page 24: ...24 Rossi HB 1 0001...