Installation of gear reducer

5

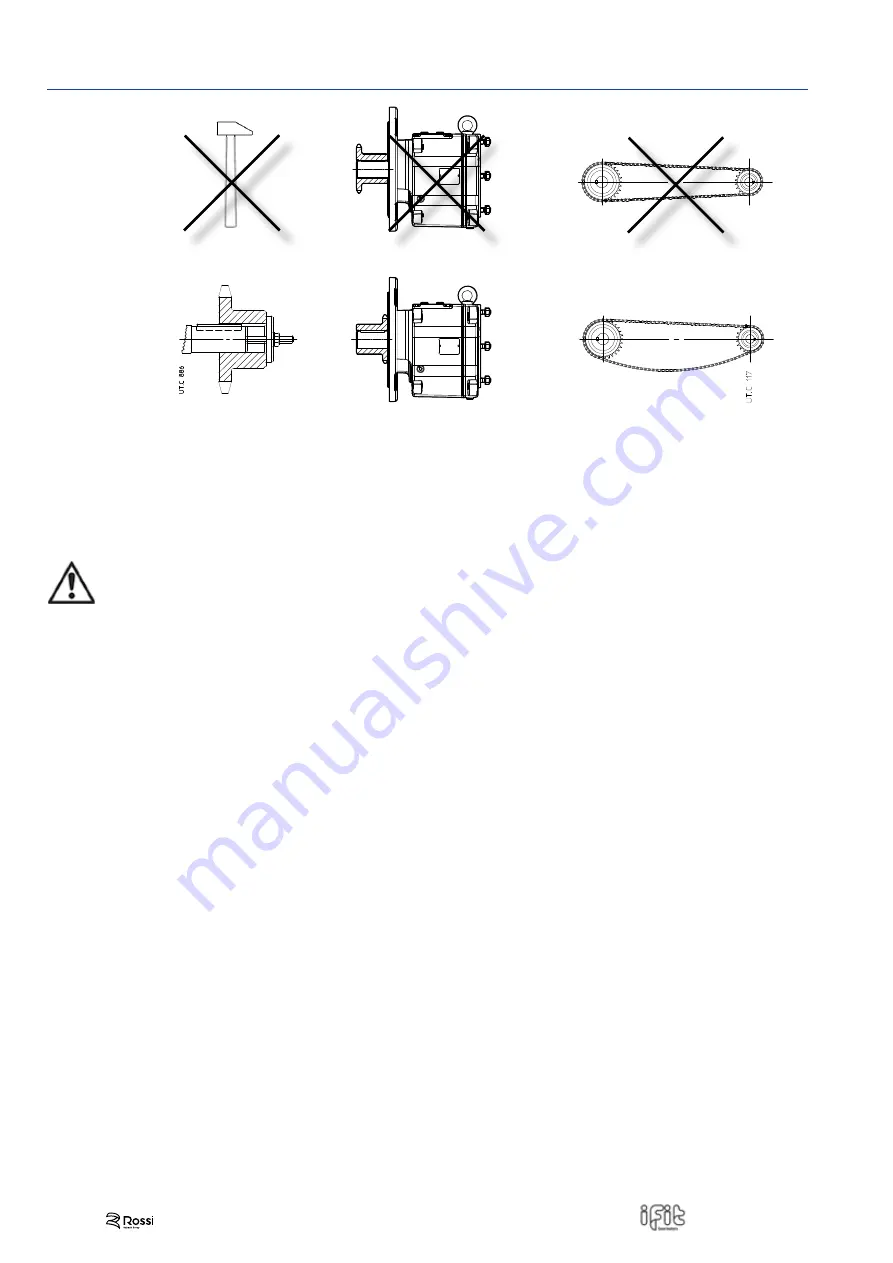

Incorrect

Correct

UT

.C. 2437

Generally, it is recommended to machine the hole of parts keyed onto shaft end, tolerance

H7

.

For low speed shaft ends, provided that load is not uniform and light, tolerance must be

K7

.

Before mounting, thoroughly clean mating surfaces with proper antirust products, and lubricate against seizure and fretting

corrosion.

Attention!

Assemble and disassemble with the aid of

jacking screws

and

pullers

using tapped holes at shaft butt-end, taking

care to avoid impacts and shocks which may

irremediably damage the bearings, the circlips or other parts.

For couplings H7/m6 and K7/j6 it is advisable that the part to be keyed is preheated to a temperature of 80 ÷ 100 °C.

The couplings having a tip speed on external diameter up to 20 m/s must be statically balanced; for higher tip speeds they must

be dynamically balanced.

Where the transmission link between gear reducer and machine or motor generates shaft end loads, ensure that: loads do not

rise above catalog values:

•

loads do not rise above catalog values;

•

transmission overhang is kept to a minimum;

•

drive-chains should not be tensioned (if necessary – alternating loads and/or motion – foresee suitable chain tighteners);

•

in the gear transmission systems there is a proper backlash (≈ 0,03 ÷ 0,04 mm) between pinion and rack;

•

drive-belts should not be over-tensioned.

18

UT.D 208-2021.12-EN