17

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

could cause personal injury or property damage.

Whenever a leakage of lubricant could cause heavy damages, increase

the frequency of inspections and/or envisage appropriate control

devices (e.g.: remote level gauge, lubricant for food industry, etc.).

In polluting surroundings, take suitable precautions against lubri-

cant contamination through seal rings or other.

For outdoor installation or in a hostile environment (atmospheric cor-

rosivity category

C3

according to ISO 12944-2), protect the gear

reducer or gearmotor with a proper dual-compound anticorrosion

paint; added protection may be afforded by applying water-proof

grease (especialIy around the rotary seating of seal rings and at shaft

end access points).

Gear reducers and gearmotors should be protected whenever pos-

sible and by appropriate means from solar radiation and extremes

of weather: protection

becomes essential

when high or low

speed shafts are vertically disposed or when the motor is installed

vertical with fan uppermost.

For ambient temperature greater than +40 °C or less than 0 °C,

consult Rossi.

When gear reducer or gearmotor is supplied with water cooling by

coil or independent cooling unit, see ch 7.

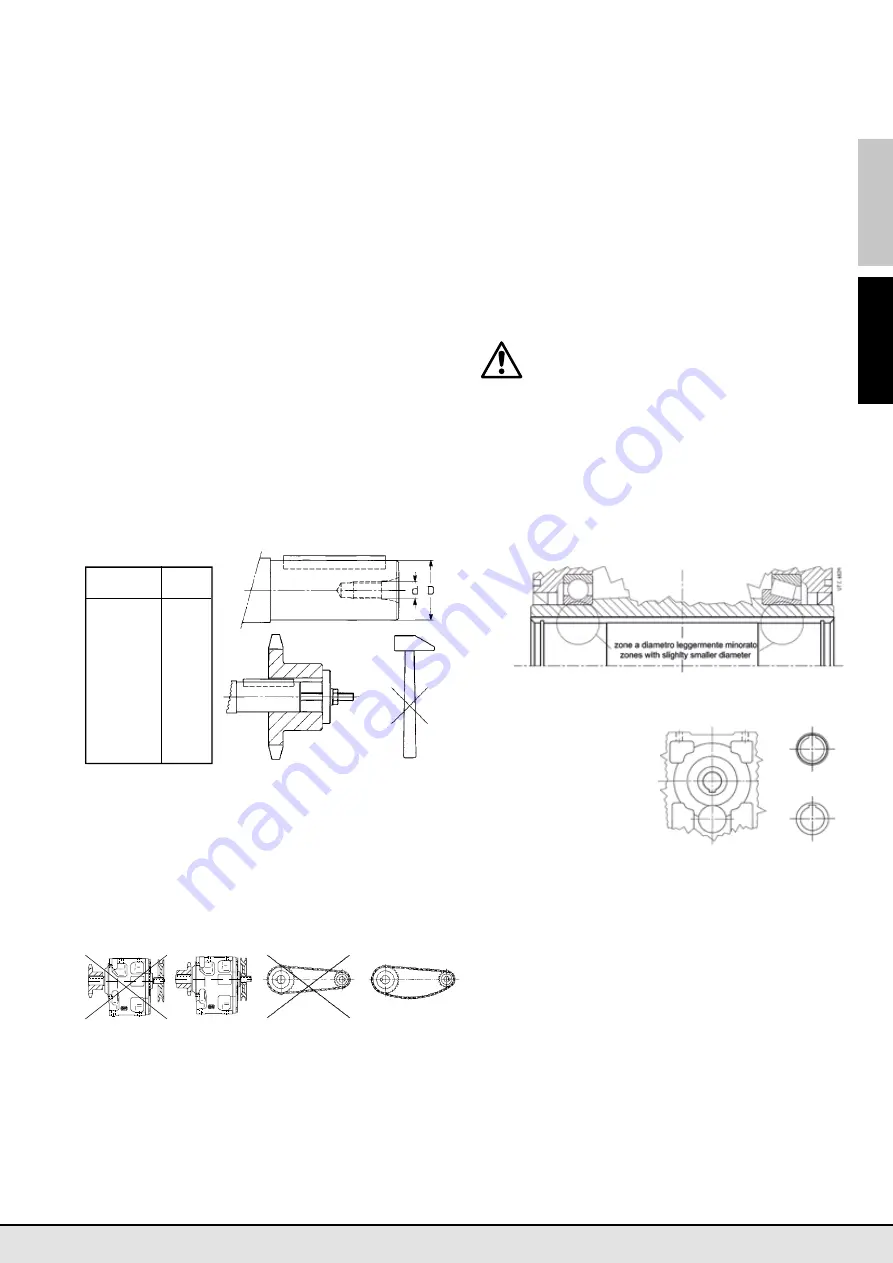

5.2 - Fitting of components to shaft ends

It is recommended that the holes of parts keyed onto shaft ends

should be machined to H7 tolerance; for high speed shaft ends hav-

ing D ≥ 55 mm, tolerance G7 is permissible provided that the load

is uniform and light; for low speed shaft end having D

≤

180 mm,

tolerance must be

K7

if load is not uniform and light.

Before mounting, thoroughly clean mating surfaces and lubricate

against seizure and fretting corrosion.

Attention!

Installing and removal operations should be carried out

with the aid of

jacking screws

and

pullers

using the tapped hole

at the shaft butt-end (see table in fig. 2) taking care to avoid impacts

and shocks which may

irremediably damage

the

bearings,

the

circlips

or other parts, for H7/m6 and K7/j6 fits it is advisable that

the part to be keyed is preheated to a temperature of 80

÷

100 °C.

D d

Ø

Ø

11

4

00

M 5

14

÷

19

M 6

24

÷

28

M 8

30

÷

38

M 10

42

÷

55

M 12

60

÷

75

M 16

80

÷

95

M 20

100

÷

110

M 24

125

÷

140

M 30

160

÷

210

M 36

240

÷

320

M 45

Shaft ends

Fig. 2

UT

.C 886

The couplings having a tip speed on external diameter up to 20 m/s

must be statically balanced; for higher tip speeds they must be

dynamically balanced.

Where the transmission link between gear reducer and machine or

motor generates shaft end loads, (see fig. 3), ensure that:

– loads do not rise above catalog values;

– transmission overhang is kept to a minimum;

– gear-type transmissions must guarantee a minimum of backlash

on all mating flanks;

– drive-chains should not be tensioned (if necessary – alternating

loads and/or motion – foresee suitable chain tighteners);

– drive-belts should not be over-tensioned.

Fig. 3

Incorrect

Correct

Incorrect

Correct

UT

.C 666

UT.C 117

5.3 - Shaft-mounting

When shaft mounted, the gear reducer must be supported both axi-

ally and radially (also for mounting positions B3 ... B8) by the machine

shaft end, as well as anchored against rotation only, by means of a

reaction having

freedom of axial movement

and sufficient

clear-

ance in its couplings

to permit minor oscillations always in evi-

dence without provoking dangerous overloading on the gear reducer.

Lubricate with proper products the hinges and the parts subject to

sliding; when mounting the screws it is recommended to apply

locking adhesives

.

For the mounting of the “kit using reaction disc springs” (sizes

≤

125

helical gear units) use the tapped butt end hole on the shaft end of

the driven machine and the flat machined chamfered surface for

compressing and fitting the disc springs into the reaction recess.

Concerning the reaction system, follow the project indications sta-

ted in the technical catalogs Rossi. Whenever personal injury or

property damage may occur, foresee

adequate supplementary

protection devices

against:

– rotation or unthreading of the gear reducer from shaft end of driven

machine following to accidental breakage of the reaction arrangement;

– accidental breakage of shaft end of driven machine.

5.4 - Hollow low speed shaft

For machine shaft ends onto which the hollow shafts of gear reduc-

ers are to be keyed, h6, j6, and k6 tolerances are recommended,

according to requirements.

Important!

The shoulder diameter of the shaft end of the driven

machine abutting with the gear reducer must be at least 1,18

÷

1,25

times the internal diameter of hollow shaft. For other data on

machine shaft end, in case of standard hollow low speed shaft,

stepped shaft, with locking rings or bush, with shrink disc see Rossi

technical catalogs.

Attention!

For

vertical ceiling-type

mounting and

only for gear reducers equipped with locking rings or

bush, gear reducer support is due only to friction, for this

reason it is advisable to provide it with a fastening sys-

tem.

When

installing

and

removing

gear reducers and gearmotors

with hollow low speed shaft incorporating a circlip groove –

whether with keyway or shrink disc – proceed as per fig. 4a and

4b, respectively, on page 14.

Warning

. Even if low speed shafts are principally machined

within H7 tolerance, a check using a plug could detect two areas

with

slightly smaller diameters

(see Fig. 5a): this reduction is

intentional and does not affect the

quality of keying

- which in

fact will be

improved

in terms of

duration

and

precision

- and it

does not represent an obstacle to the assembly of a machine shaft

end executed according to the usual methods, such as to the one

shown on Fig. 4a.

Fig. 5a

In order to remove the hollow low speed shaft of the helical and bevel

helical gear reducers (this is the first operation to perform when disassem-

bling the gear reducer) turn the

shaft until the keyway is fac ing the

intermediate shaft as indicated in

fig. 5b and push the shaft from the

reference groove side (circumfer-

encial keyway on shaft shoulder).

The system shown in fig. 4c and

4d, page 14, is good for

axial

fastening

; when the shaft end of

the driven machine has no shoul-

der (as in the lower half of the

drawing) a spacer may be located

between the circlip and the shaft end itself. Parts in contact with the circlip

must have sharp edges.

The use of

locking rings

(fig. 4e, page 14) or

locking bush

(fig. 4f page

14) will permit easier and more accurate installing and removing and elimi-

nate backlash between the key and keyway.

The locking rings or bush are fitted after mounting and after having care-

fully degreased the coupling surfaces. Do not use molybdenum bisulphide

or equivalent lubricant for the lubrication of the parts in contact. When

tightening the bolt, we recommend the use of a

locking adhesive

.

Respect the tightening torques stated in the table on page 24.

In case of axial fastening with locking rings or bush – especially when hav-

ing heavy duty cycles, with frequent reversals – verify, after some hours of

running, the bolt tightening torque and eventually apply the locking adhe-

sive again.

When fitting with

shrink disc

(fig. 4g, page 14) proceed as follows:

– carefully degrease the surfaces of hollow shaft and shaft end of driven machine to be

fitted;

– mount the gear reducer onto the shaft end of driven machine following the method

indicated in fig. 4a, page 14;

– gradually and uniformly tighten the screws of shrink disc by a continuous sequence

(not crossing) and during several phases up to a torque stated in the table on page 24;

– at operation end verify the screw tightening torque by means of a dynamometric key

(flat, when it is mounted onto machine end).

groove side

d

opposite side to groove

Fig. 5b

UT.C 322