18

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

6.2 - Lubrication table

Independently-lubricated bearings, motor-bearings, backstop device fitted to motor:

lubrication is «

for life

» (except some cases of motors in which relubrication device is adopted). Should there be either a possibility of the grease

becoming contaminated, or a very heavy type of duty-cycle, it is good policy to check on the state of the grease (between one change and the

next, or every year or 2 years) and remove and replace grease in independently-lubricated bearings (every change or every other change, or every

2 or 4 years). Bearings should be filled with SHELL Gadus S2 V100 bearing-grease for ball bearings, KLÜBER STABURAGS NBU 8 EP for roller

bearings; lubricate the backstop device with SHELL Alvania RL2.

Product

How supplied* and plugs

Directions for first filling

Worm

sizes

32 ... 81

Worm

sizes

100 ... 250

Coaxial

sizes

32 ... 41

Right angle

shaft

(cat. L)

sizes

80 ... 125

Coaxial

sizes

50 ... 81

Helical

and

bevel helical

sizes

40 ... 81

Coaxial

sizes

100 ... 180

Helical

and

bevel helical

sizes

100 ... 631

Right angle

shaft

(cat. L)

sizes

160 ... 320

Shaft mounted

FILLED WITH

SYNTHETIC OIL

AGIP Blasia S 320, KLÜBER

Klübersynth GH 6-320,

MOBIL Glygoyle HE 320,

SHELL Omala S4 WE 320

Worm speed

280 min

-1

KLÜBER Klübersynth GH6-680

MOBIL Glygoyle HE 680

SHELL Omala S4 WE 680

Filler plug

1 filler plug sizes 32 ... 64

Filler/drain plug

2 filler/drain plugs for sizes 80, 81

WITHOUT OIL

(except different statement on

lubrication name plate)

Filler plug with valve,

drain and level plug

Before putting

into service, fill

to specified level

with

synthetic

oil

(AGIP Blasia S,

ARAL Degol GS,

BP-Energol SG-XP,

MOBIL Glygoyle,

SHELL Omala S4

WE ... , KLÜBER

Klübersynth GH6...)

having the ISO visco-

sity grade given in

the table.

FILLED WITH

SYNTHETIC GREASE

SHELL Gadus S5 V142W00

IP Telesia Compound A

MOBIL Glygoyle Grease 00

Filler/drain plug

(only for coaxial)

FILLED WITH

SYNTHETIC OIL

KLÜBER Klübersynth GH 6-220

MOBIL Glygoyle 30

SHELL Omala S4 WE 220

Filler/drain plug

2 filler/drain plugs for sizes 80, 81

WITHOUT OIL**

(except different statement

on lubrication name plate)

Filler plug with valve

(with breathing for shaft

mounted gear reducers),

drain and level plugs

Before putting into service,

fill to specified level with

mineral oil

(AGIP Blasia,

ARAL

Degol BG, BP-En-

ergol GR-XP, IP Mellana

oil, MOBIL Mobilgear 600

XP, SHELL Omala S2 G,

TEXACO Meropa, TOTAL

Carter EP) or

poly glycol**

synthetic oil

(KLÜBER

Klübersynth GH6 ..., MOBIL

Glygoyle, SHELL Omala S4

WE) or

polyalphaolefi-

nes** synthetic oil

(AGIP

Blasia SX, CASTROL Alphasyn EP, ELF Reductelf SYNTHESE, SHELL Omala S4 GX, KLÜBER

Klübersynth GEM4, MOBIL SHC Gear) having the ISO viscosity grade given in the table.

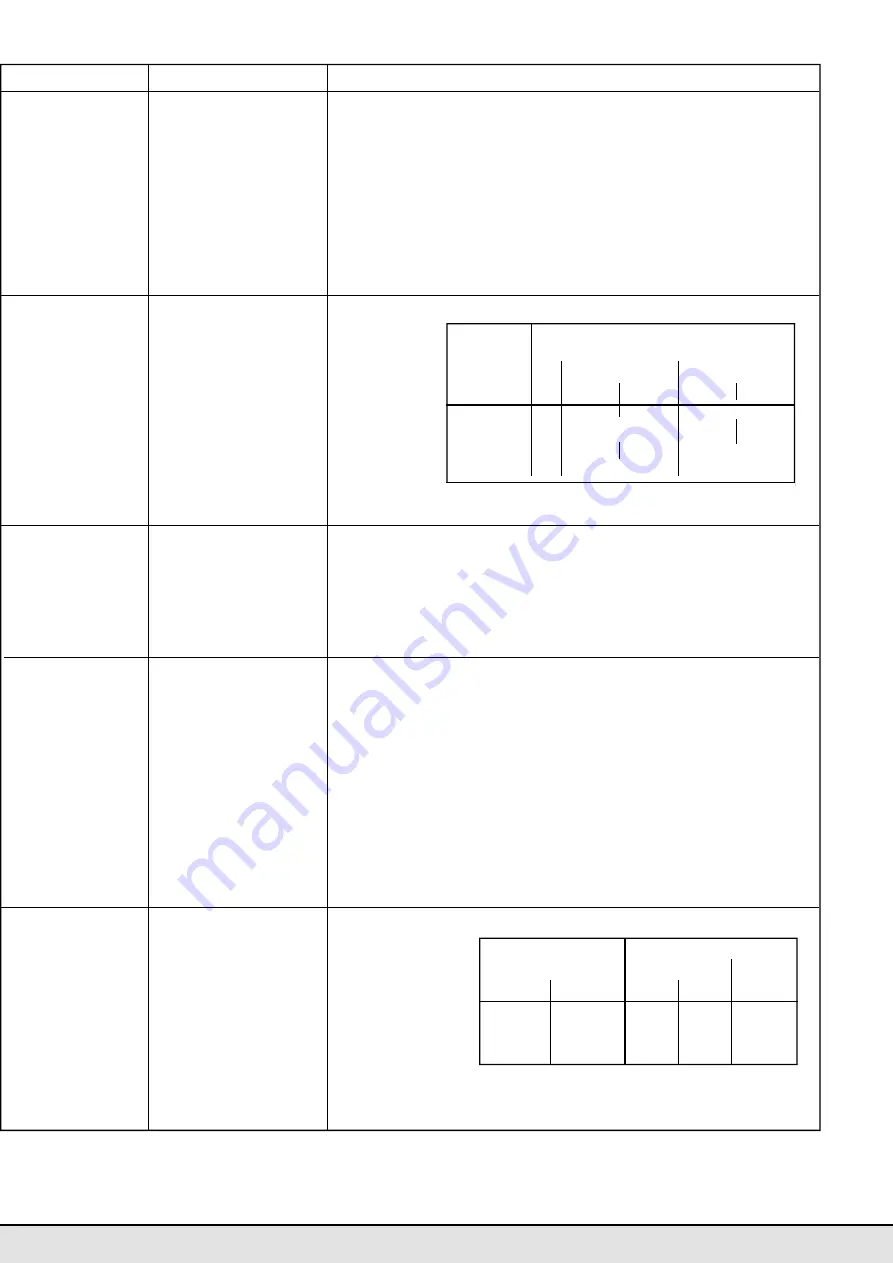

ISO viscosity grade [cSt]

Ambient temperature 0

÷

+40 °C

2)

Worm speed

Gear reducer size

min

-1

100

125 ... 161

200, 250

B3

1)

, V5, V6 B6, B7, B8 B3

1)

, V5, V6 B6, B7, B8

2 800

÷

1 400

3)

320 320 220

220

1 400

÷

710

3)

320 320

320 220

710

÷

355

3)

460 460

460 320

355

÷

180

3)

680 680 460

460

<

180

680 680

680

1) Not stated on the name plate.

2) Peaks of 10 °C above and 10 °C (20 °C for

≤

460 cSt) below the ambient tem-

perature range are acceptable.

3) For these speeds we advise to replace oil after running-in.

ISO viscosity grade [cSt]

Speed

n

2

Ambient temperature

1)

[°C]

min

-1

mineral oil

synthetic oil

Bevel

helical Others 0

÷

20 10

÷

40

0

÷

40

>

710

000

>

224

150 150 150

710

÷

280

224

÷

22,4

150 220 220

280

÷

90 22,4

÷

5,6

220 320 320

<

90

000

<

5,6

320 460 460

1) Peaks of 10 °C (20 °C) below and 10 °C above the ambient temperature

range are acceptable.