Betriebsanleitung

TGT, 26.06.2017

Technik

Seite 46 von 52

©Copyright by Habegger Maschinenfabrik AG

Version 03 / 26.06.2017

7

Maintenance

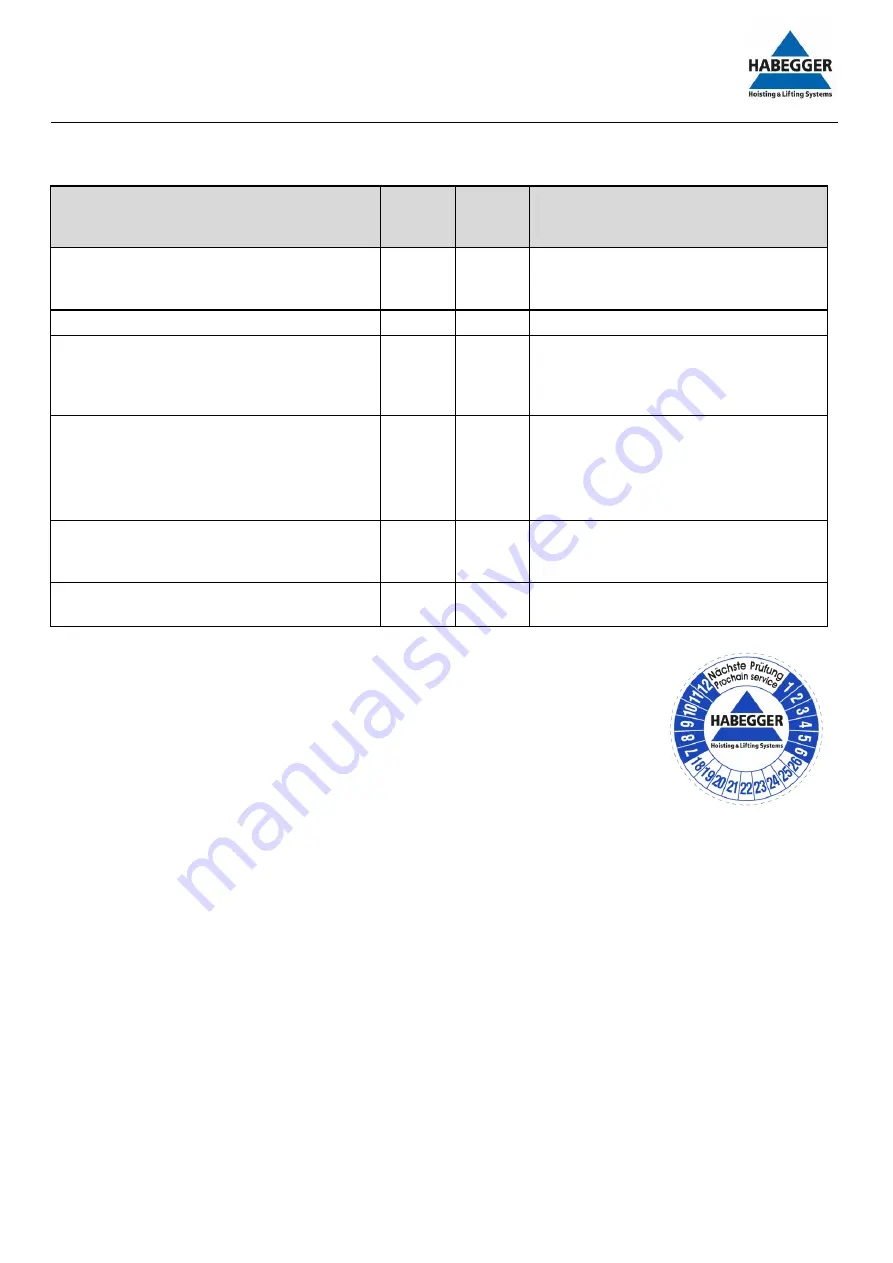

Perform the following checks and maintenance work:

Work

when

starting

work

as

needed

Remarks

General visual inspection:

- casing

- anchor bolts and retaining disc

X

X

Screw inspection

X

After first use or modification

Cleaning

X

In the event the device is very dirty, clean with

a pressure washer

If necessary, disassemble the casing and re-

move dirt/foreign objects

Lubrication

X

Drizzle in engine oil

After using a pressure washer:

Soak the device in engine oil and let the oil

drip off.

The clamping jaws and rope must remain dry.

Rope: Visual inspection

– Clamp

– Load hook with catch

X

X

Check for deformation, damage or breaks

Rope: Diameter check

X

if the rope is worn, replace it

See Chapter 3 for values

The device, rope and accessories must be checked by an expert at least every 2 years (see sticker

on device). All of the parts will be checked for deformation, wear and tear and cracks. The inspec-

tion results must be entered into an inspection log or on page 4 of this booklet.

The operator must order the inspections.

Additional inspections must also be performed by an expert at shorter intervals in accordance

with the local regulations and under harsh operating conditions.

8

Disposal

Comply with national disposal regulations.

When disassembling the device, separate defective parts by material type as much as possible in order to recycle them:

Store or recycle metal and plastic parts separately.

Remember, protecting the environment and recycling materials benefits us all.

Replacement parts lists

The replacement parts lists for the four pulley devices can be found on the last pages of these instructions.