User Guide

TGT. 12.03.2019

Technical

Page 20 of 21

©Copyright by Habegger Maschinenfabrik AG

Version 03 / 12.03.2019

6.1

Emergency lowering

Optional emergency operation controls

If the control system is equipped with emergency operation controls, the power unit’s frequency converter can be bypassed.

The load can be hoisted and lowered in this manner.

Switch on emergency operation

Switch off emergency operation

1.

press EMERGENCY STOP button

1.

press EMERGENCY STOP button

2.

switch on emergency operation

2.

switch off emergency operation

3.

release EMERGENCY STOP button

3.

release EMERGENCY STOP button

7

Maintenance

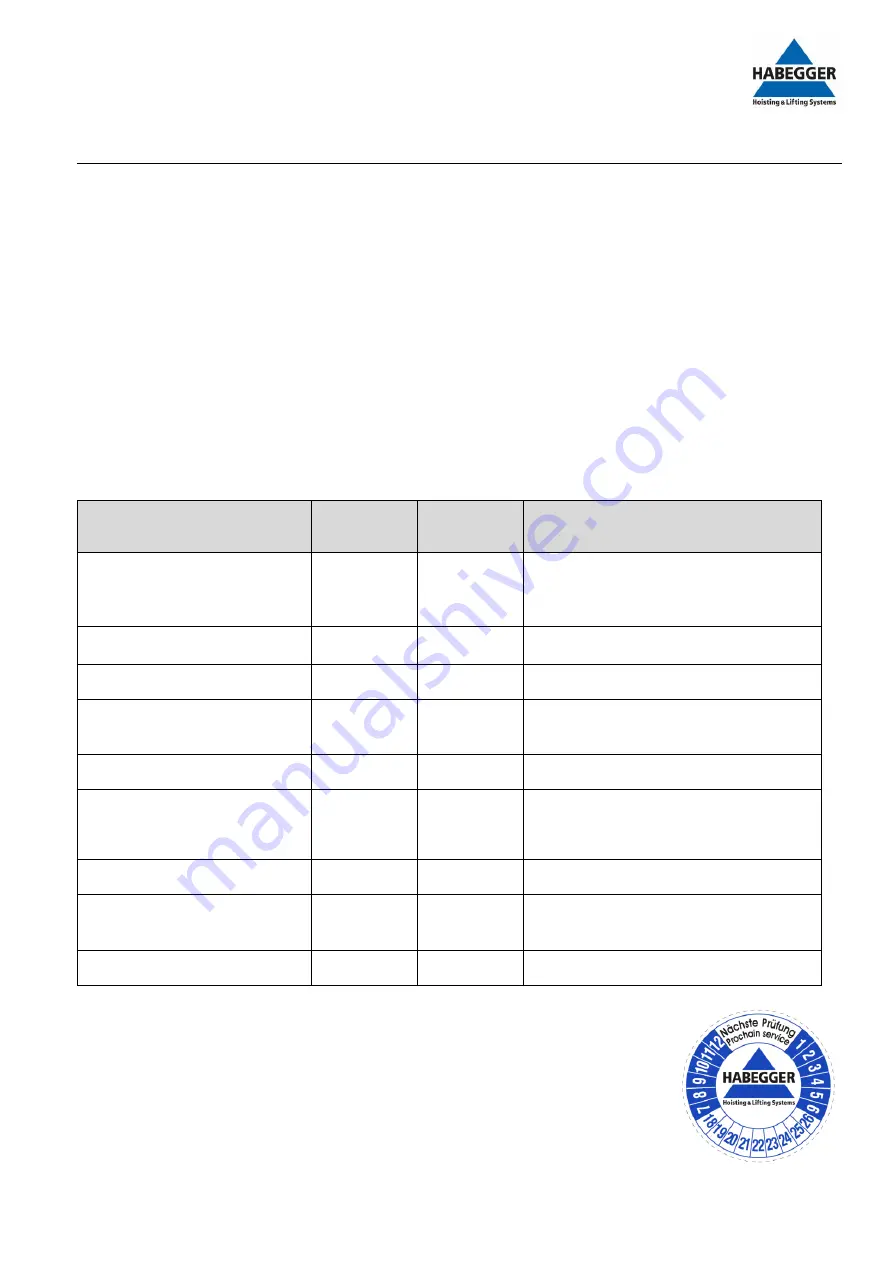

The following checks and maintenance work should be carried out:

Task

At the start of

operation

As required

Comments

General visual checks:

- driving system

- housing

- Anchor bolts, anchoring straps

X

Screw check

X

after first use or

Overhauls

Clean driving wheel

X

Direction of rotation for electric mo-

tor

X

X

UP button =

Rotation of driving wheel in

anticlockwise direction

Sprocket re-lubrication

X

Gear grease

Rope: Visual checks

- compression sleeve

- eye hooks with fastenings

X

Checking for deformities,

Damage, tears

or broken wires

Rope: Cleaning

X

Rope: Diameter check

X

for worn out ropes,

when rope diameter < 26 mm

Change the rope!

Oil level in sight gauge

X

The machine, the rope and the accessories must be checked at least every 2 years (see sticker

on machine) by a qualified professional. In this way all parts will be checked for deformities,

wear and tear, and cracks. The results of these checks should be entered into the test book.

The checks should be arranged by the operator.

Additionally, local regulations, as well as additional checks for severe operating conditions in

short operating distances, must be implemented by a qualified professional.

8

Replacement parts

Replacement parts are provided on a separate list. This can be requested from HABEGGER.