(

In case of doubt on the pump or any circulation devices, please contact After Sales Service directly, co

ntact details in the following affix.

the address or telephone number where the consumer/installer can obtain additional information during

the installation in the event of problems.)

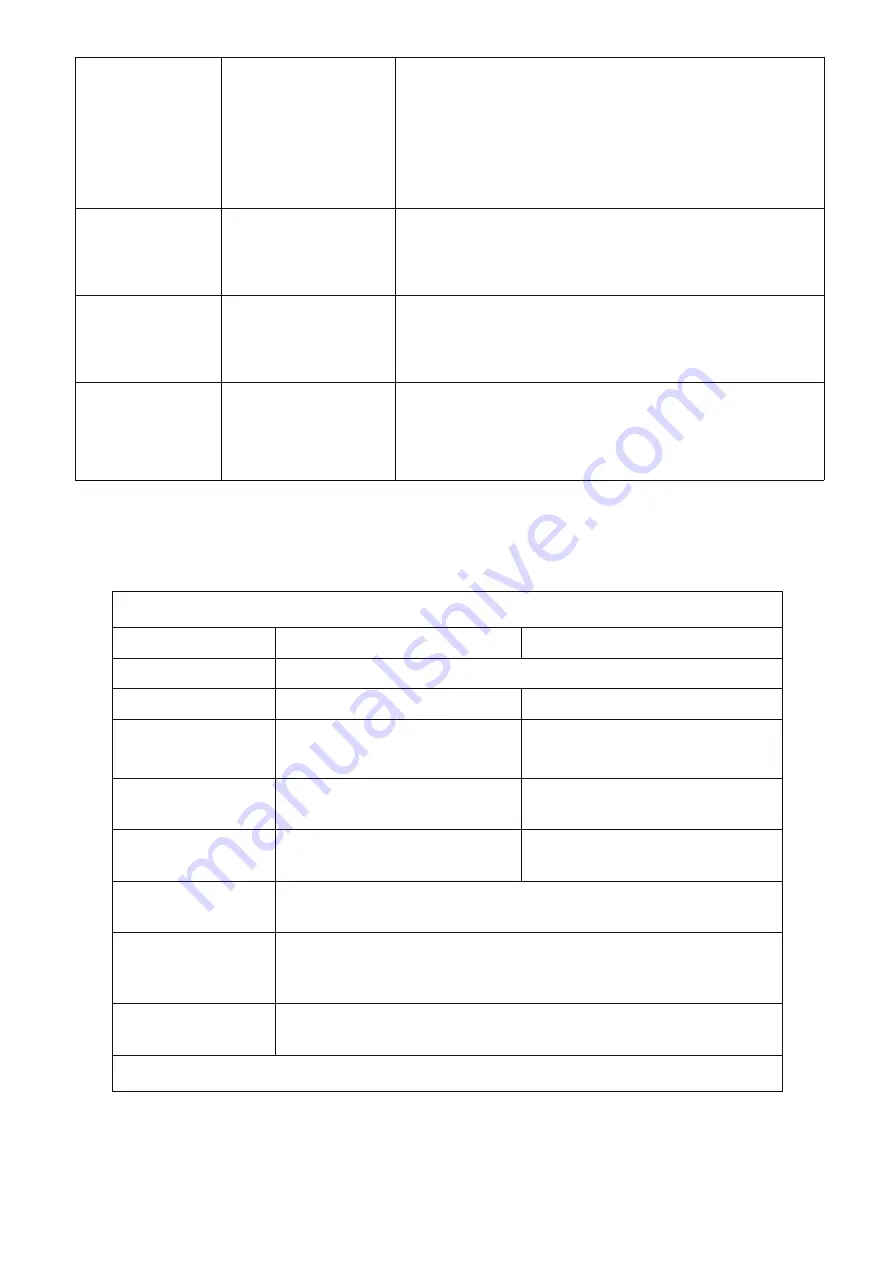

The control valve or

its upper cover is

leaked

The body seal is lost

The body seal is too

dirty

The control valve buckle

is not fastened

The control valve is

damaged

Remove the upper control valve cover and install the body seal

Use a water hose to clean the body seal

Use a screwdriver to tighten the bolt

Please contact Customer Service Center for replacement

The

bellows

is

leaked

The bellows hoop is not

tightened

The water port seal is

lost

Tighten the hoop

The water port seal is no damaged in place

The pressure gauge

does not action

The inner wall of the

pressure

gauge

is

blocked

Pressure gauge damage

Remove the pressure gauge from the control valve and clean the

impurities on the inner wall

Please contact Customer Service Center for replacement

The sand enters into

the tank

The sand particles are

too fine

Use only No. 20 silica sand, with the sand particle size of

0.45-0.85 mm

ˈ

˄

i.e. 0.018-0.033 inches

˅

, and the overall particle

uniformity coefficient of which is smaller than 1.75.

Or replace the sand

Product specifications

Model

103109

BC002A

Voltage

220-240V

Power

60W

90W

Maximum operating

pressure

<0.2bar (3psi)

<

0.3(4.5psi)

Effective

filtrating

area

0.058m² (0.62ft²)

0.058m² (0.62ft²)

Maximum water flow

rate

800 gallons/hr (3028 l / h)

1000 gallons/hr (3785 l / h)

Maximum

water

temperature

35

℃

Recommended filter

media

20# quartz sand or glass sand, with particle size of 0.45-0.85 mm

,

(

i.e. 0.018-0.033 inches

)

, and the overall particle uniformity

coefficient of which is smaller than 1.75.

Recommended

number of media

Quartz sand or glass sand, 10 kg

Please read carefully and save it for future reference

Summary of Contents for 103109

Page 1: ...6DQG ILOWHU PDQXDO...

Page 3: ...List of parts in the package box Optical...

Page 4: ...LJ...