Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

5

5.

Storage

Prior to storage, inspect the valve for shipping damage. Keep all protective

packaging, flange covers and end caps attached to the valves during storage. It is

recommended to keep the valves in a clean and dry environment until it is ready

for use.

Carbon Steel valves have a

“black

o

xide”

and oil dipped finish. This nontoxic process

is performed to retard rusting during storage. It is not a substitute for paint or other

means of protective coating to be applied to the valve once installed.

Stainless steel valves have their natural finish and do not need any additional protection once

installed.

5.1.

L ong Term Storage

5.1.1.

It is advisable to store the valves in waterproof conditions. Ball valves

should be protected to safeguard against humidity, Moisture, dust, dirt,

sand, mud, salt spray, and sea water.

5.1.2.

Manual ball valves must remain in the open position during the period of storage.

5.1.3.

Actuated valves (fail to close position) remain in closed position during this time.

5.1.4.

Valves may be stored as shipped, provided the above storage location and

equipment orientation instructions are followed

5.1.5.

In order to prevent damage, protective covers on valve ends should

not be removed until immediately prior to installation.

5.1.6.

Visual inspection should be performed on a semi-annual basis and results recorded.

6.

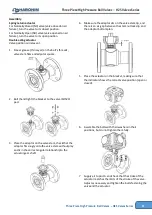

Installation

The installation procedure for Habonim ball valves is critical to ensuring both long life

and satisfying performance. Valves stored on site, awaiting installation, should be

kept in their original packing, in dry conditions, where damage will not occur (See

Para. 4).

Before carrying out the installation, it is important to follow the basic procedures described

below:

6.1.

G e ne ral

6.1.1.

It is essential to flush the line prior to assembling any valve on the line.

6.1.2.

Carefully unpack the valve and check valve nameplate for identification of materials.

6.1.3.

Remove any special packing materials surrounding the valve.

6.1.4.

Check the valve for the flow direction indication marks. Appropriate care must be

taken, to install the valve for proper flow orientation.

6.1.5.

Inspect the valve interior through the end ports to determine it is clean and free

from foreign matter according to ASME G93-03E1.

6.1.6.

Cycle the valve and inspect any functionally significant features.

6.1.7.

Read all the literature and note any special warning tags or plates attached to the valve.

6.1.8.

Before installation check to insure that the flow line balls are in the fully open

position in order to prevent possible damage to the balls and seats. The valve

performance depends on its original conditions. At any stage do not leave the

valve in the partially open position on either of the lines.