12

5.52.624.01.01.00

108/22

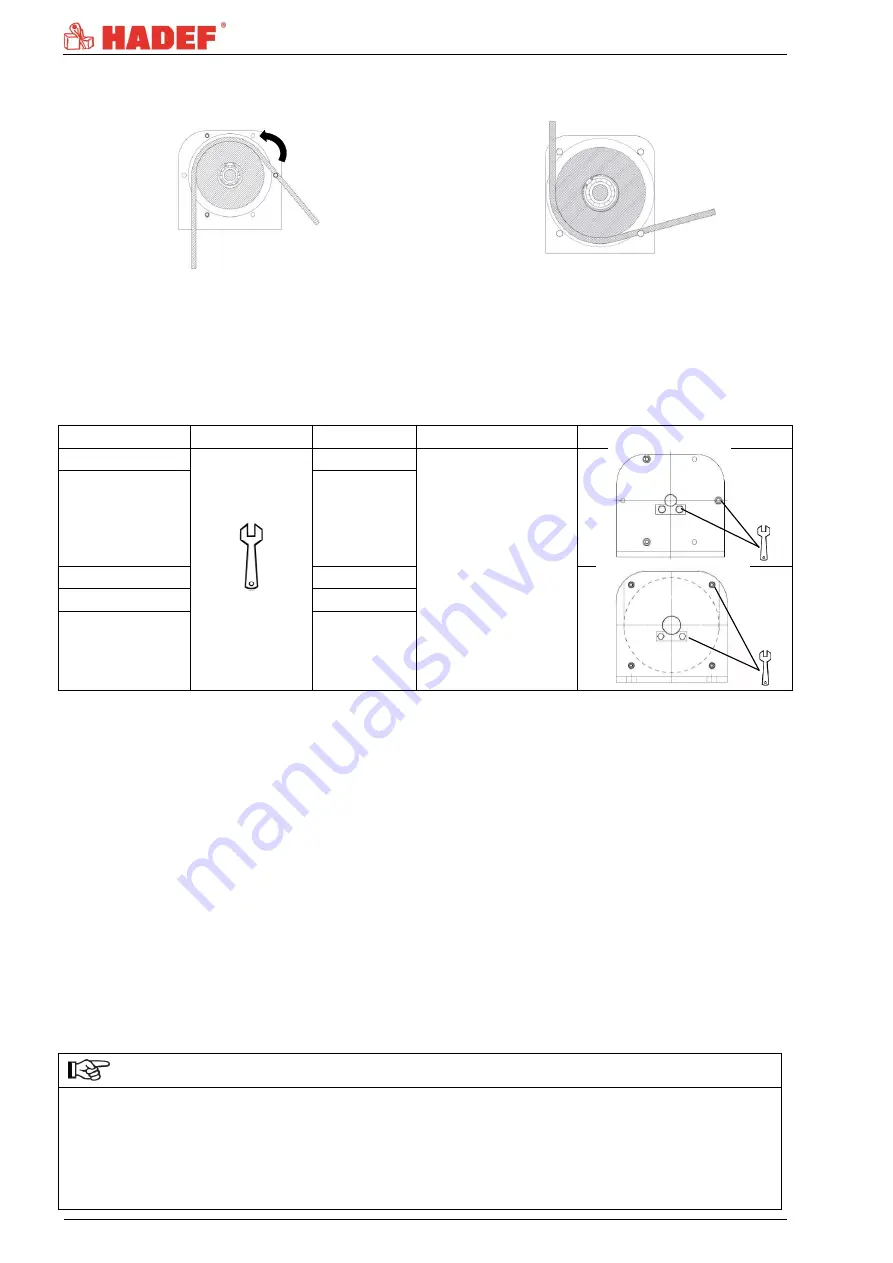

For rope exits at certain angles, individual rope slip off guard can be moved or removed.

up to 1000kg

from 2000kg

To prevent the rope from slipping off when slack, the rope must be guided under at least one rope slip off

guard.

6.3

Tools

108-22

7

Control

Only people that are familiar with the operation of the lifting devices and cranes may be entrusted with their

operation. They must be authorized by the employer for the operation of the equipment. The employer must

ensure that the operating instructions are available near the equipment and that they are accessible for the

operating personnel.

Only use wire ropes, that do not exceed the maximum permitted diameter.

Put the wire rope properly on the pulley and ensure that the rope rests on the groove base.

Check screw connections.

8

Commissioning

8.1

General

The operator of the unit is responsible for the entire system.

According to the Ordinance on Industrial Safety and Health, a hazard analysis must be carried out by the

operator.

Observe the respective national standards, regulations and directives of the responsible bodies at the place

of operation.

NOTICE!

Hoists up to 1000 kg capacity and without motor-driven trolleys of hoisting unit must be tested by a

“qualified person” before putting into operation for the first time.

Hoists of 1000 kg capacity and up or with more than one motor-driven hoist movement; i.e. lifting and

trolley movement, must be

tested by a “licensed qualified person” before putting in operation.

An exception is “hoists ready for operation” acc. validated national regulations with EU-declaration of

conformity.

capacity

tool

size

usage

250kg

– 500kg

M6

axial securing

Rope slip off guard

1000kg

M8

2000 - 5000kg

M10

12500kg

M16

20000kg

M20