5.52.624.00.01.01

9

10

Maintenance

10.1

General

All monitoring, servicing and maintenance operations are to ensure correct functioning of the equipment;

they must be effected with utmost care.

Only

“qualified persons” may do this work.

Servicing and maintenance work must only be done when the hoist is not loaded.

Records must be kept of all test results and measures taken.

10.2

Monitoring

The monitoring and servicing intervals stated are valid for operation under normal conditions and single-shift

operation. In case of severe operating conditions (e.g. frequent operation with full load) or special

environmental conditions (e.g., heat, dust, etc.), the intervals must be shortened correspondingly

11

Inspection

11.1

Periodic checks

Independently from the regulations of the individual countries, lifting devices must be checked at least yearly

by a qualified person or licensed qualified person regarding its functional safety.

11.2

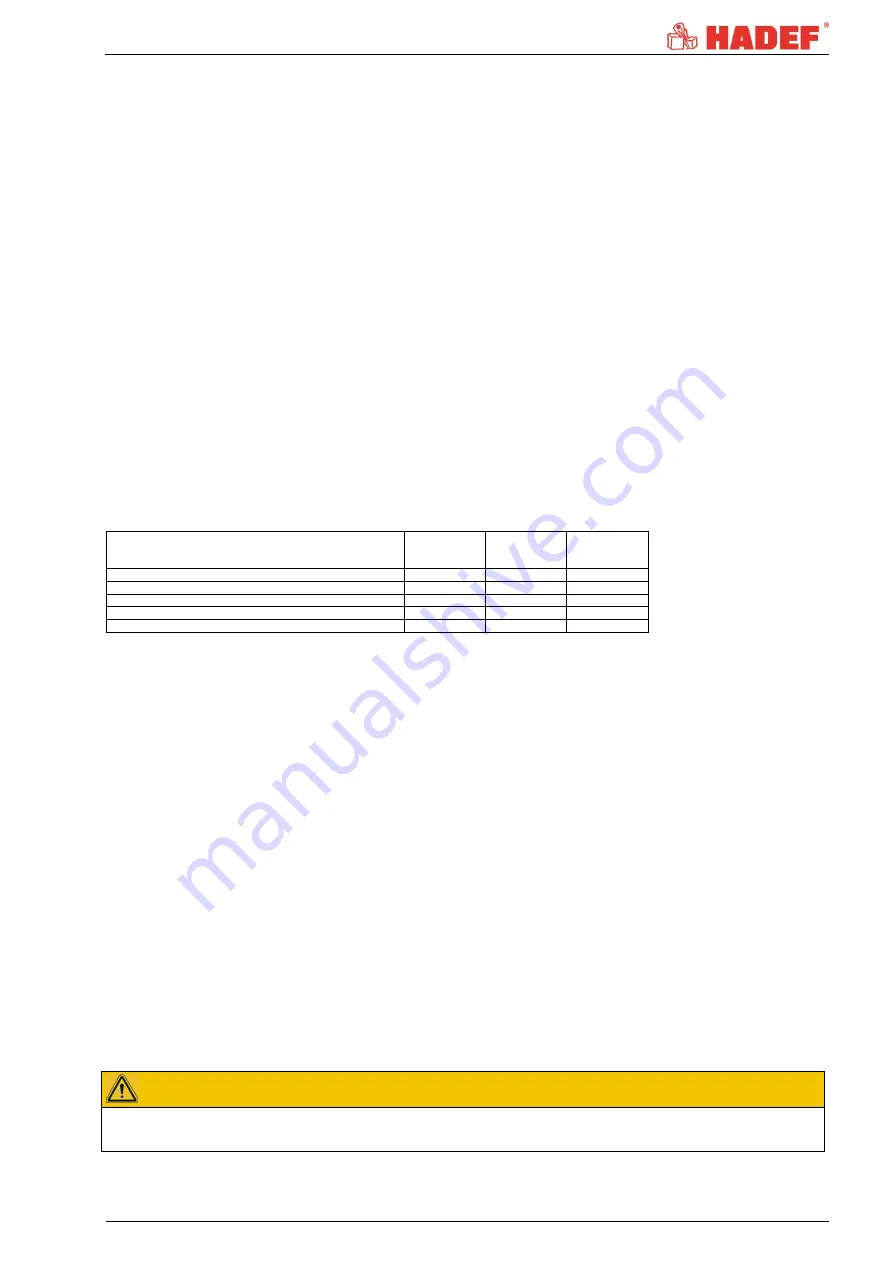

Inspection intervals

daily

checks

inspection,

service every

3 months

inspection,

service every

12 months

check screw connections

X

check wear and tear of rope pulley

X

check smooth running of rope pulley

X

check smooth running of rope within pulley

X

equipment check by a qualified person (periodic inspection)

X

11.3

Inspection

Examine for bearing damage.

The rope pulley should have a firm seating on ist axle and should turn smoothly.

Check for wear and tear.

The wire rope must not stick in the groove and has to be liftable effortlessly.

12

Service

The wire rope pulley and the ball bearings are maintenance-free.

13

Trouble

Please pay attention to the following in case of problems:

Troubles with the equipment must only be repaired by qualified personnel.

Secure the unit against unintended operation start.

Put up a warning note indicating that the unit is not to be used.

Secure the working area of moving parts of the unit.

Please read the chapter "Safety instructions".

Notes on the repair of faults are found in the following table.

For the repair of failures please contact our service department.

CAUTION!

Trouble caused by wear or damage to parts such as wire ropes, chains, chain wheels, axes, bearings,

brake parts, etc., must be remedied by replacing the parts with original spare parts.